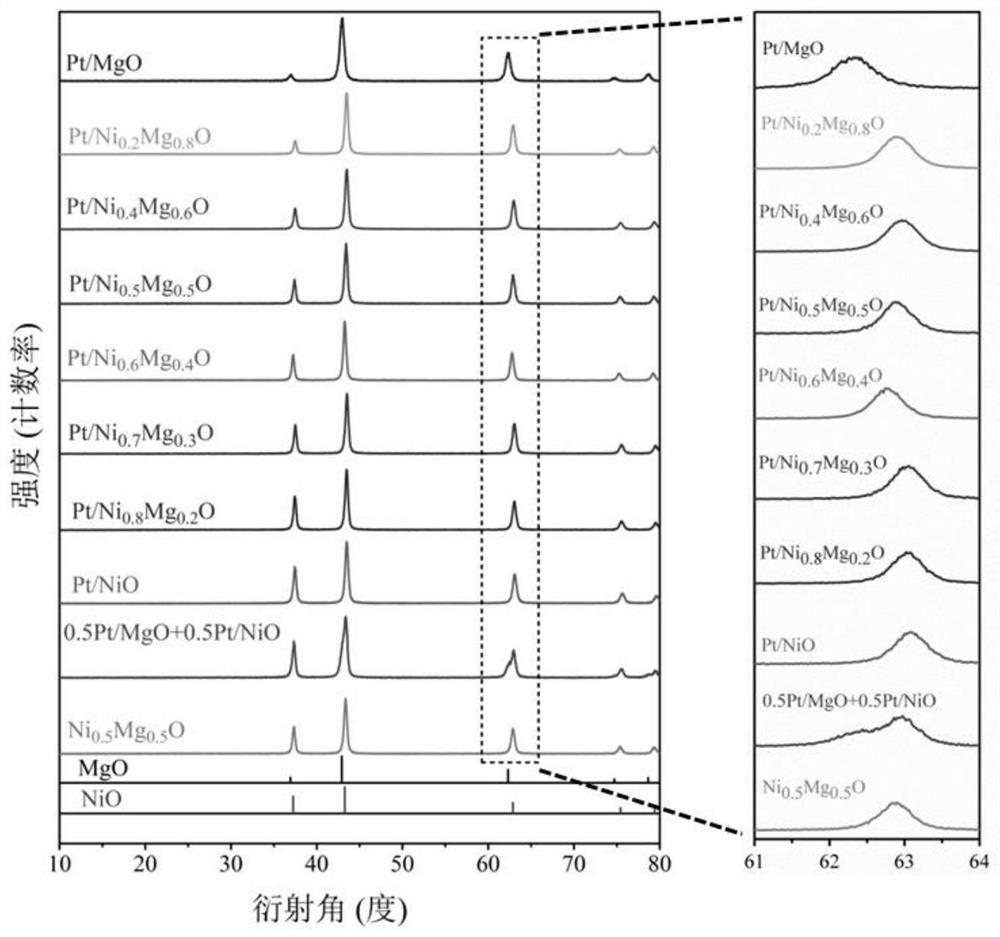

A kind of preparation method of nickel-magnesium solid solution catalyst

A solid solution and catalyst technology, applied in the field of preparation of nickel-magnesium solid solution catalyst, can solve problems such as scarcity, and achieve the effects of wide temperature window, high catalytic activity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

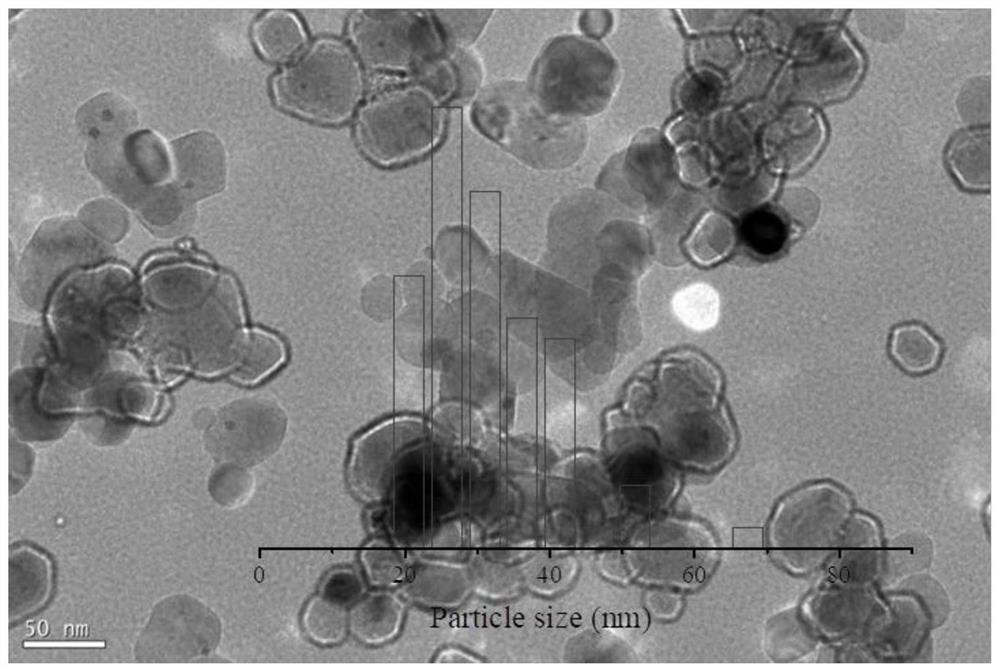

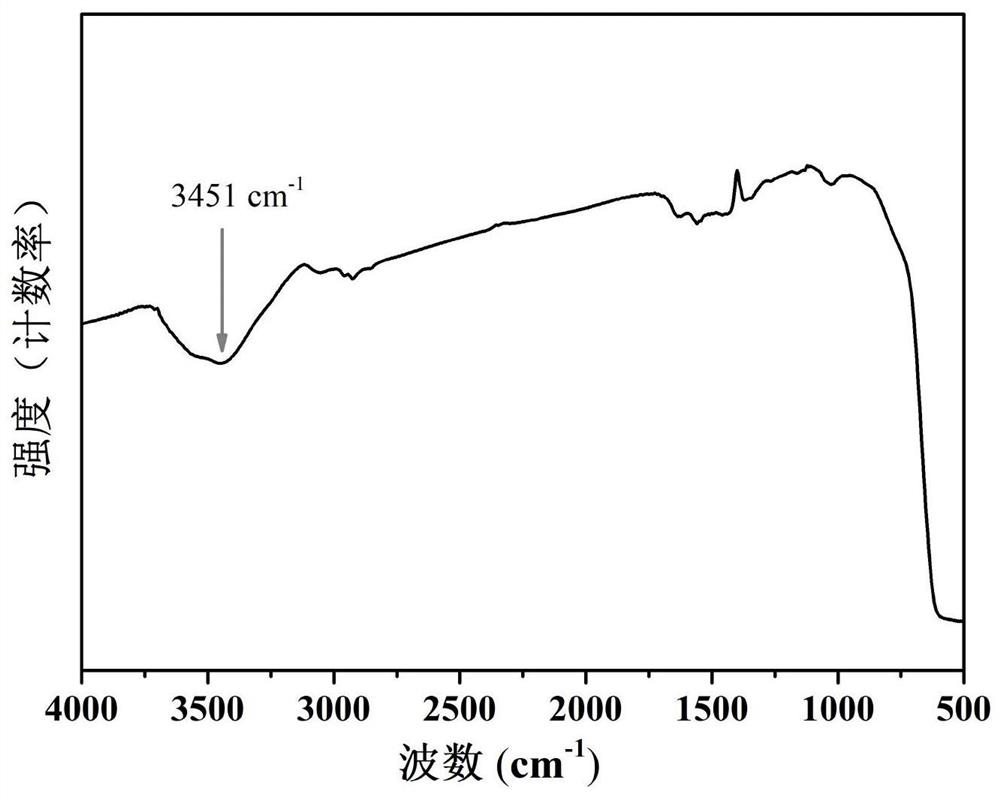

[0031] Embodiment 1 preparation sample #1 nickel-magnesium molar ratio is 1:0.5 flake nickel-magnesium solid solution catalyst carrier

[0032] Dissolve 10mmol of magnesium chloride hexahydrate in 100ml of distilled water and stir to dissolve, then add dropwise 10ml of NaOH solution (concentration is 2mol / L) and stir for 15 minutes, then continue to add 10mmol of nickel chloride hexahydrate to the solution, stir and dissolve, then pour into the solution Add 10ml of NaOH solution dropwise and continue to stir for 1h, let stand for a while, wash with a large amount of distilled water, filter with suction, dry at 60°C overnight to obtain a light green precursor, grind the precursor evenly, and roast at 500°C 5h, the heating rate was 2°C / min to obtain the final black powder sample. The catalytic reaction conditions are: the temperature range of the catalytic reaction: 30-240°C, the pressure is 0.2Mpa, and the reaction space velocity is 80000h -1 , gas composition: CO: 1%, O 2 :1...

Embodiment 2

[0033] Embodiment 2 preparation sample #2 nickel-magnesium molar ratio is the plate-shaped nickel-magnesium solid solution catalyst carrier of 0.8:0.2

[0034] Dissolve 2mmol of magnesium chloride hexahydrate in 100ml of distilled water and stir to dissolve, then add dropwise 10ml of NaOH solution (concentration is 2mol / L) and stir for 15 minutes, then continue to add 10mmol of nickel chloride hexahydrate to the solution, stir and dissolve, then pour into the solution Add 10ml of NaOH solution dropwise and continue to stir for 1h, let stand for a while, wash with a large amount of distilled water, filter with suction, dry at 60°C overnight to obtain a light green precursor, grind the precursor evenly, and roast at 500°C 5h, the final black powder sample with a heating rate of 2°C / min. The catalytic reaction conditions are: the temperature range of the catalytic reaction: 30-240°C, the pressure is 0.2Mpa, and the reaction space velocity is 80000h -1 , gas composition: CO: 1%, ...

Embodiment 3

[0035] Embodiment 3 preparation nickel-magnesium molar ratio is the flaky nickel-magnesium solid solution catalyst support of 0.7:0.3

[0036] Dissolve 4mmol of magnesium chloride hexahydrate in 100ml of distilled water, stir and dissolve, then add dropwise 10ml of NaOH solution (concentration is 2mol / L) and stir for 15 minutes, then continue to add 10mmol of nickel chloride hexahydrate to the solution, stir and dissolve, then pour into the solution Add 10ml of NaOH solution dropwise and continue to stir for 1h, let stand for a while, wash with a large amount of distilled water, filter with suction, dry at 60°C overnight to obtain a light green precursor, grind the precursor evenly, and roast at 500°C 5h, the final black powder sample with a heating rate of 2°C / min. The catalytic reaction conditions are: temperature range of catalytic reaction: 30-240°C, pressure 0.2Mpa, reaction space velocity 80000h-1, gas components: CO: 1%, O 2 :1.25%, H 2 : 50%, He balance. The flaky n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com