Partitioned side wall friction stir welding integration universal fixture

A friction stir welding and side wall technology, applied in manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of reducing the service life of the fixture, low work efficiency, and large storage space for the fixture, and achieves a flexible pressing position and takes up space. Small, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

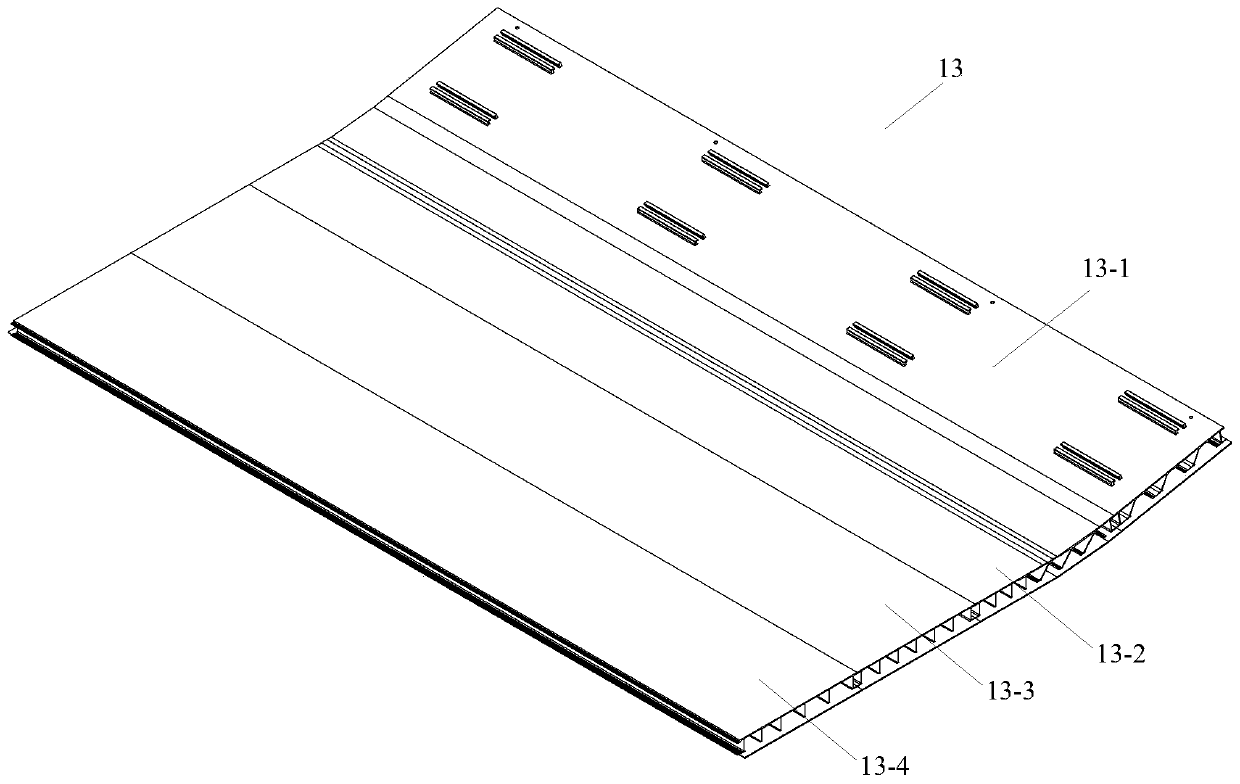

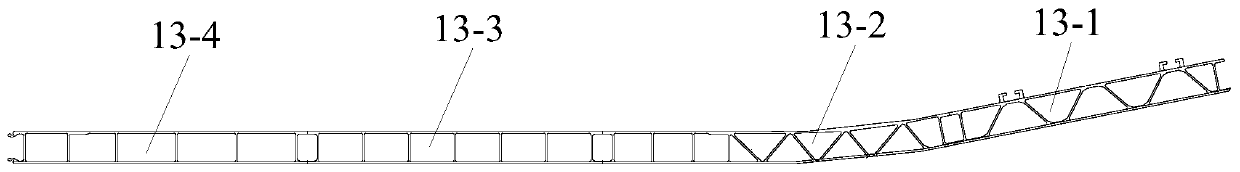

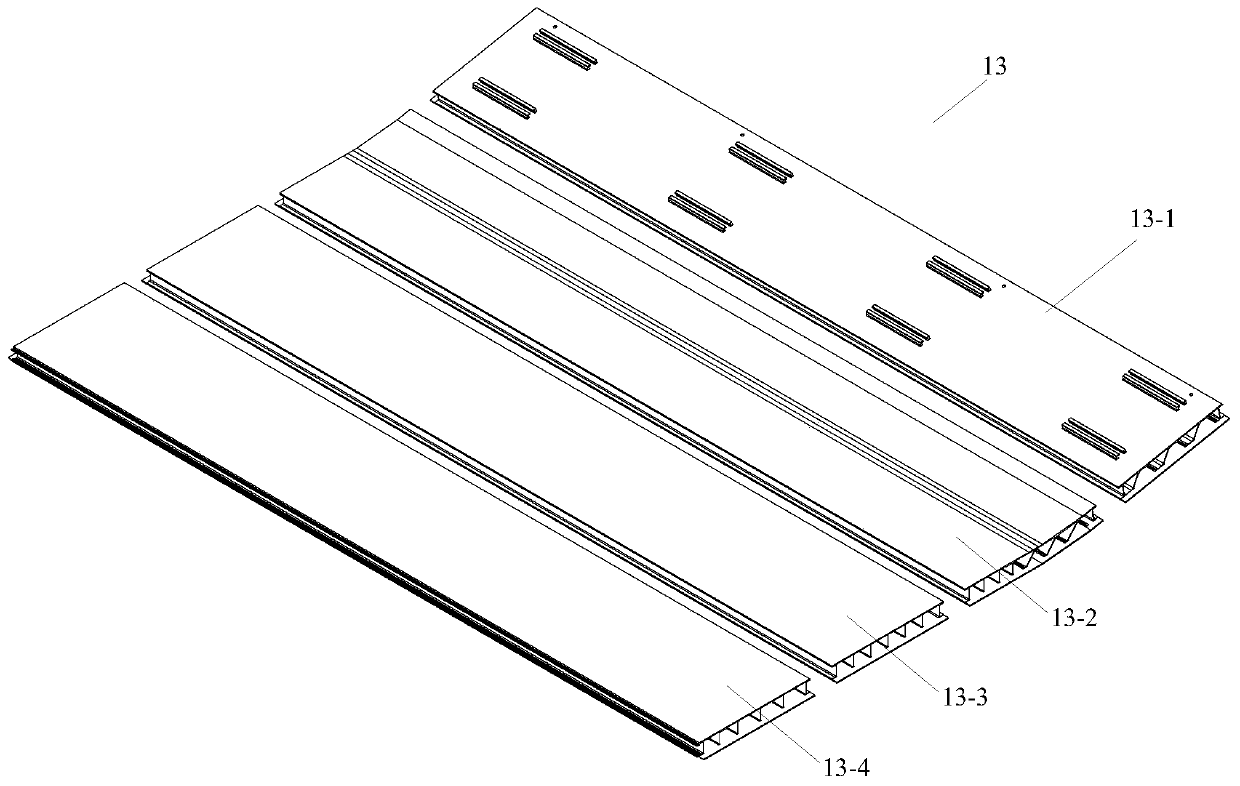

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Such as Figure 4 to Figure 15 As shown, the block side wall friction stir welding integrated universal fixture of the present invention includes: a clamp body, a moving clamping mechanism, multiple horizontal clamps 7, multiple C-shaped clamps 8 and multiple vertical clamps 9.

[0036] The clamp body includes a plurality of parallel beams 1, a plurality of parallel longitudinal beams 2, a plurality of lateral limit plates 3, a plurality of horizontal compactor mounts 4, and a plurality of vertical compactor mounts 5 and a plurality of connection seats 6, a plurality of beams 1 and a plurality of longitudinal beams 2 are interlaced and vertically fixed to form a basic support frame of the clip body, and a plurality of connection seats 6 are symmetrically fixed on the bottom end surface of the outer ring of the above-mentioned basic support frame.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com