Crushing machine of raw material for preparing wood shaving artificial board

A raw material and shredder technology, which is applied in the field of particleboard manufacturing, can solve the problems of easy damage of cutting tools, fixed wood limit, cumbersome replacement of tools, etc., and achieves the effect of reducing hidden dangers, stable structure and large quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

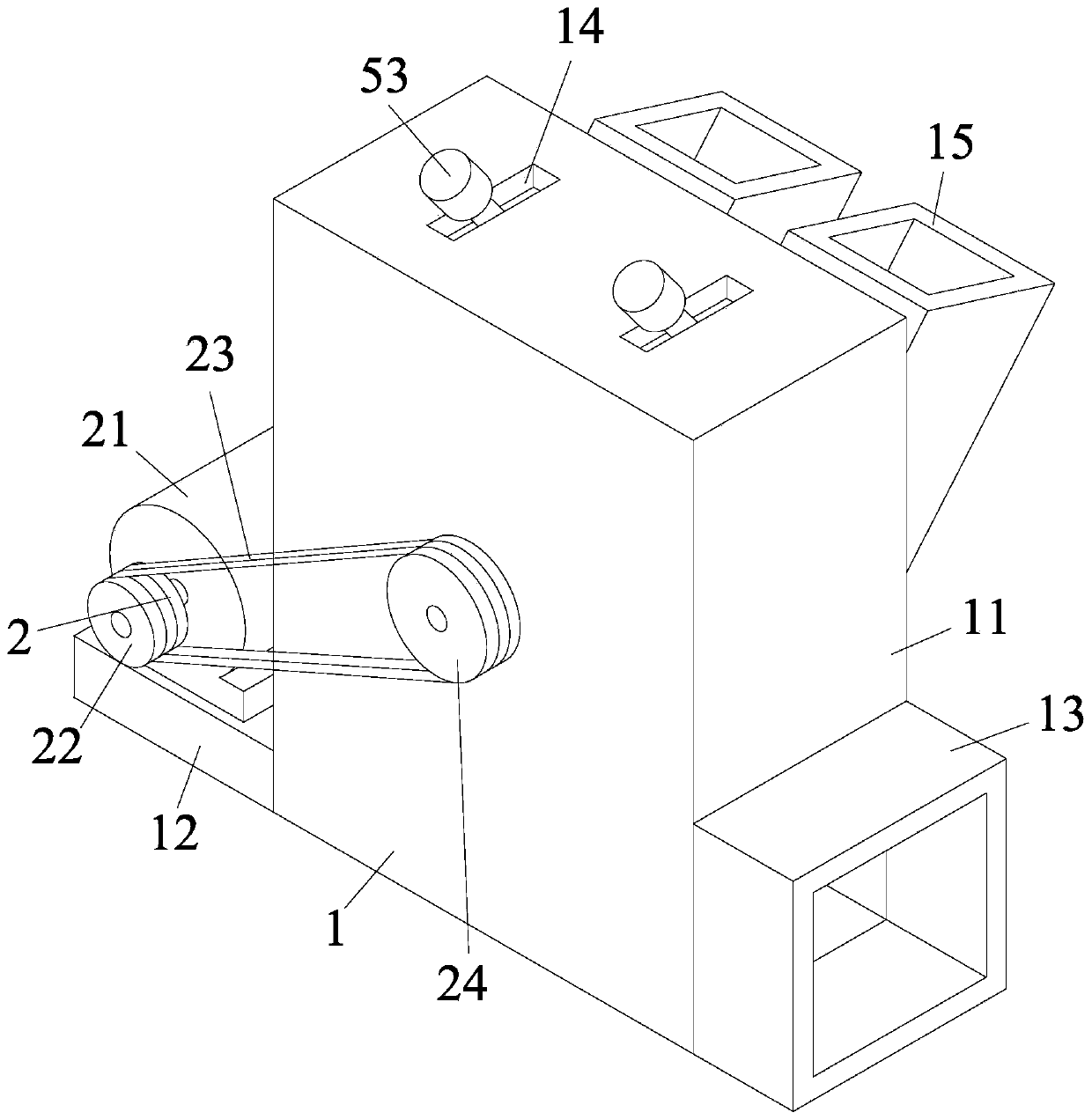

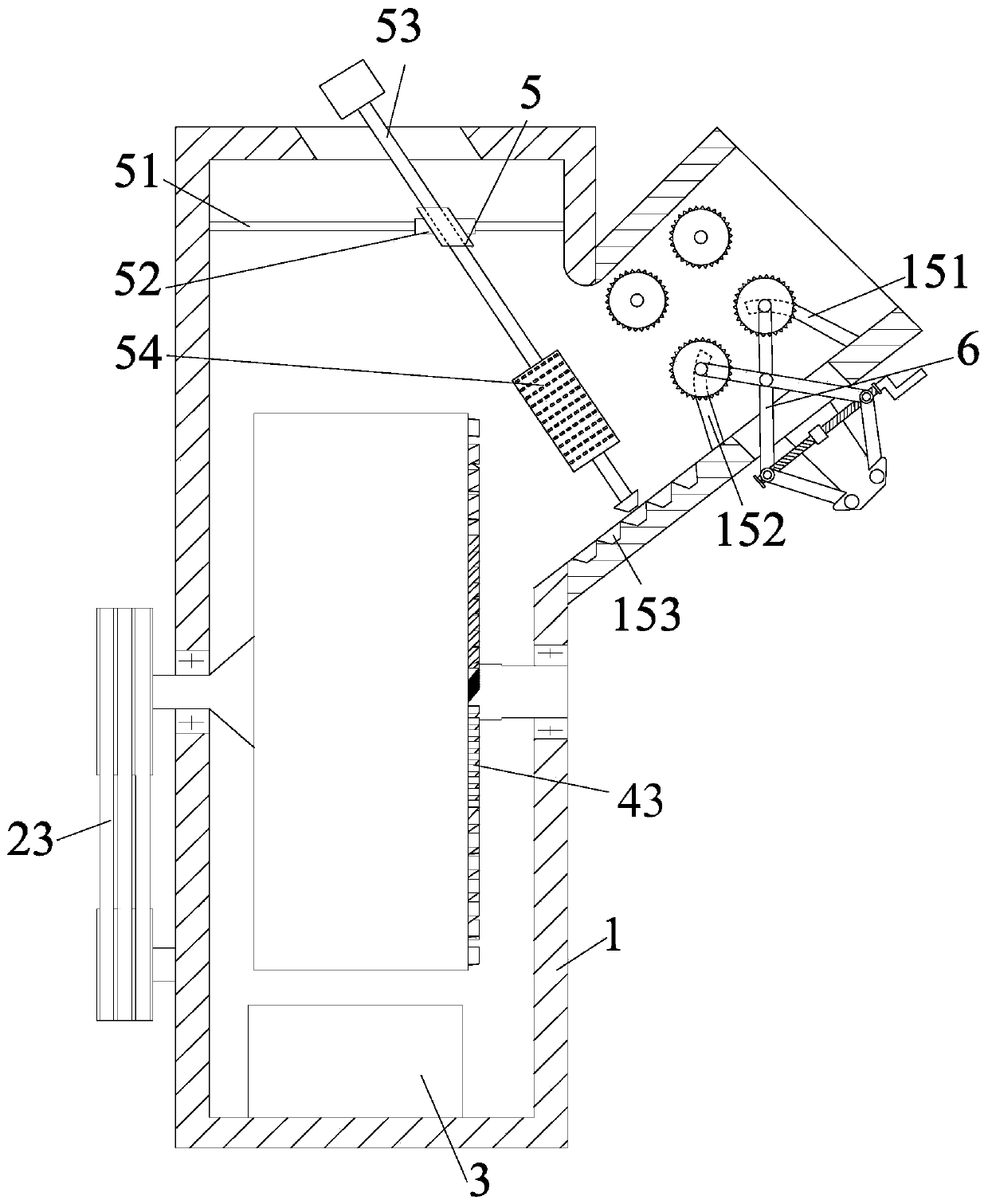

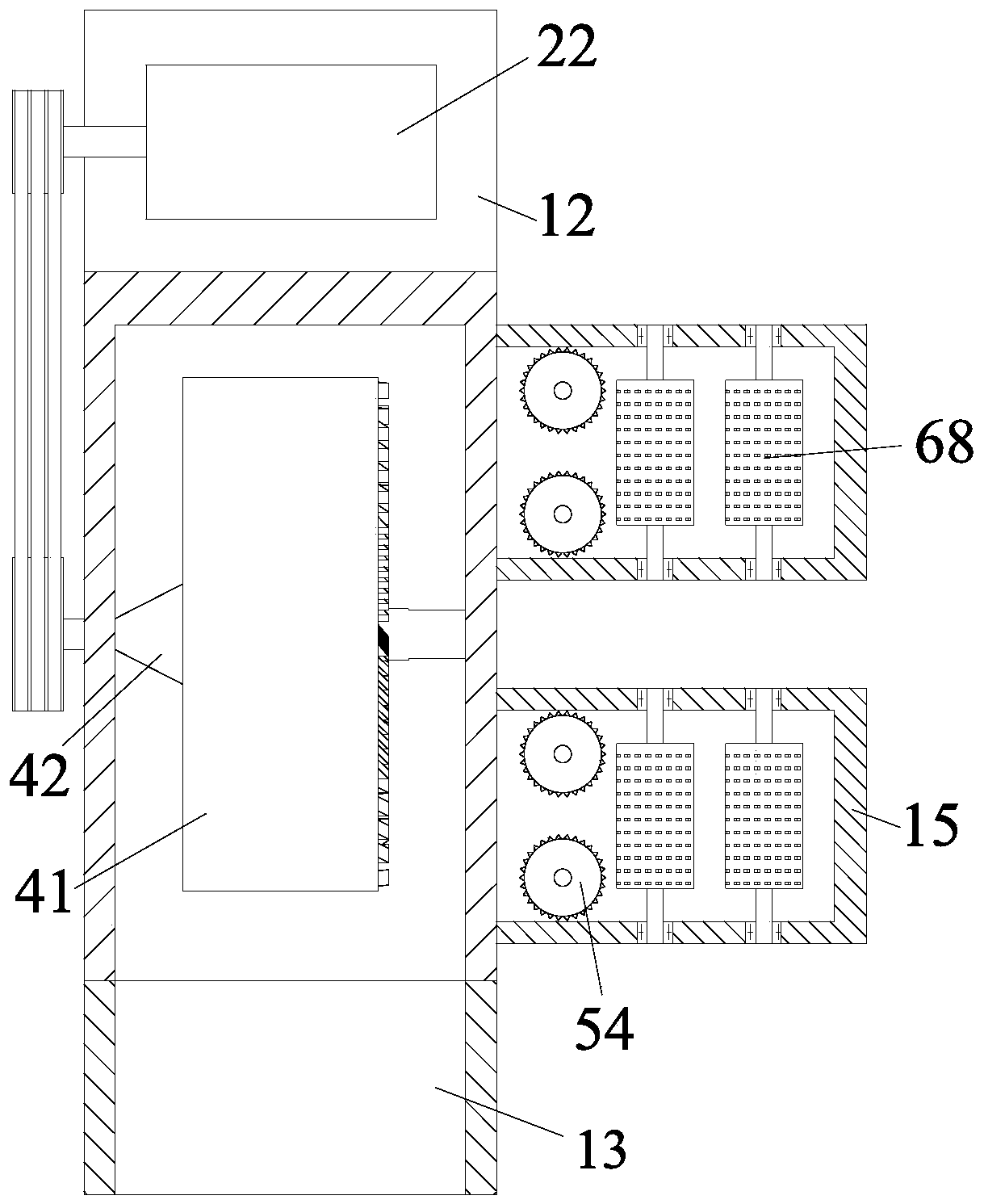

[0035] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following is combined Figure 1 to Figure 8 , To further explain the present invention.

[0036] A shredder for preparing raw material from particle-based wood-based panels, comprising a box body 1, a driving device 2, a blower 3, a shredder device 4, an auxiliary fixing device 5 and a feeding device 6. A driving device 2 is installed on the front side of the box body 1 A blower 3 is installed at the lower end of the box 1, a crushing device 4 is installed in the middle of the box 1, and the crushing device 4 is located at the upper end of the blower 3, an auxiliary fixing device 5 is installed at the upper end of the box 1, and a feeder is installed at the right end of the box 1. 料装置6; Among them:

[0037] The box body 1 includes a housing 11, a motor mounting plate 12, a discharge port 13, a rectangular groove 14 and two feed ports 15. The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com