A crane time optimal anti-sway control method and system

A time-optimized, control-system technology, applied in design optimization/simulation, load suspension components, geometric CAD, etc., can solve problems such as affecting the safety of crane operation, increasing displacement, and difficulty in crane operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

[0028] The cart of the crane refers to the bridge running mechanism of the crane, and the trolley is the operating part of the hoisting mechanism.

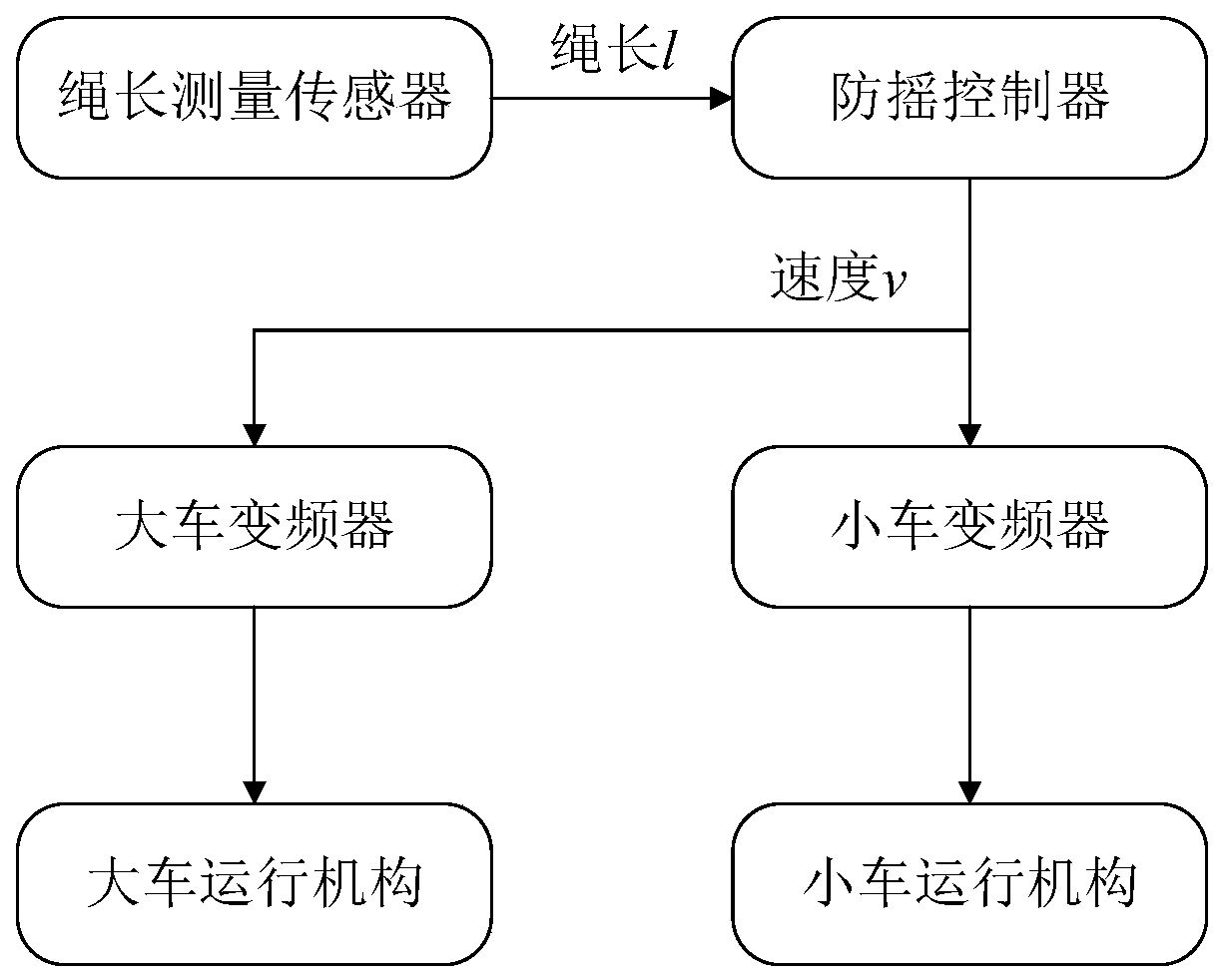

[0029] The control system adopted by the crane time optimal anti-sway control method of the present invention mainly includes a rope length measuring sensor, an anti-sway controller, a cart inverter, a trolley inverter, a cart operating mechanism and a trolley operating mechanism. The rope length measuring sensor can be an encoder, a distance measuring sensor, etc., which are used to measure the length of the hoisting rope in real time and transmit it to the anti-sway controller in real time. The anti-sway controller can be an industrial computer, PLC, embedded control system, etc., according to the real-time measurement of the rope length, setting the running speed of the cart and the trolley, and using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com