Comprehensive waste acid utilization device

A technology for supporting the bottom plate and the reaction box, which is applied to the control of water treatment parameters, water/sludge/sewage treatment, water pollutants, etc. It can solve the problems that affect the user's experience of using the waste acid recycling device and the treatment effect is poor. Achieve the effects of improving user experience, increasing neutralization speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

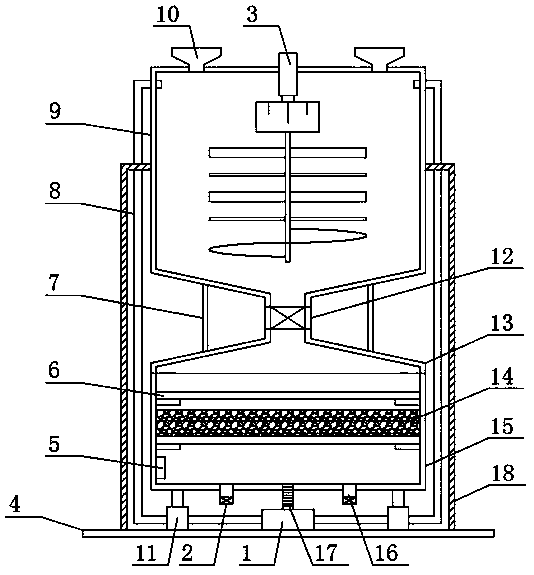

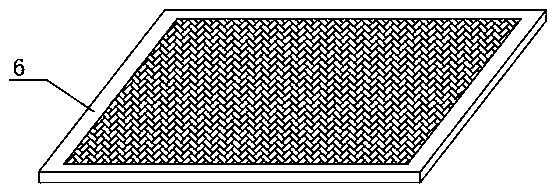

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a waste acid comprehensive utilization device, including a support base plate 4, a reaction box 9 is arranged above the support base plate 4, and a support member 18 is welded at the connection between the support base plate 4 and the reaction box 9, and the reaction The two ends of the upper surface of the case 9 are welded with a feed hopper 10, the bottom of the reaction case 9 is provided with a liquid storage tank 15, and the bottom of the reaction case 9 is provided with a top cover 13 corresponding to the liquid storage case 15, and the reaction case 9 is connected to the liquid storage case 15. The joint of the top cover 13 is provided with a second electromagnetic valve 12, and the two ends of the upper surface of the support base plate 4 are provided with the first hydraulic cylinder 11 corresponding to the liquid storage tank 15, and the top of the liquid storage tank 15 is provided ...

Embodiment 2

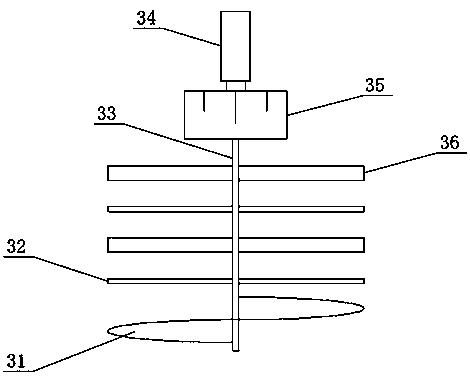

[0026] On the basis of Embodiment 1, in order to enrich the functions of the waste acid comprehensive utilization device, in this embodiment, preferably, the top of the reaction box 9 is provided with a stirring mechanism 3, and the stirring mechanism 3 includes a second hydraulic cylinder 34. The second hydraulic cylinder 34 is fixedly connected with the reaction box 9 by welding, the bottom end of the second hydraulic cylinder 34 is welded with a driving motor 35, the output end of the driving motor 35 is welded with a transmission rod 33, and the two sides of the transmission rod 33 are welded with stirring parts 36. The drive motor 35 is electrically connected to the power supply through a switch. When in use, the power supply of the drive motor 35 is turned on, so that the drive motor 35 drives the stirring member 36 to rotate through the transmission rod 33, so that the waste acid in the reaction tank 9 is treated by the stirring member 36. Stir with calcium carbonate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com