Environmental-protection ship ballast water treatment system

A technology of ship ballast water and treatment system, which is applied in the field of ship system, can solve the problems of microbial invasion and pollution, and achieve the effect of reasonable structure and environmental protection of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

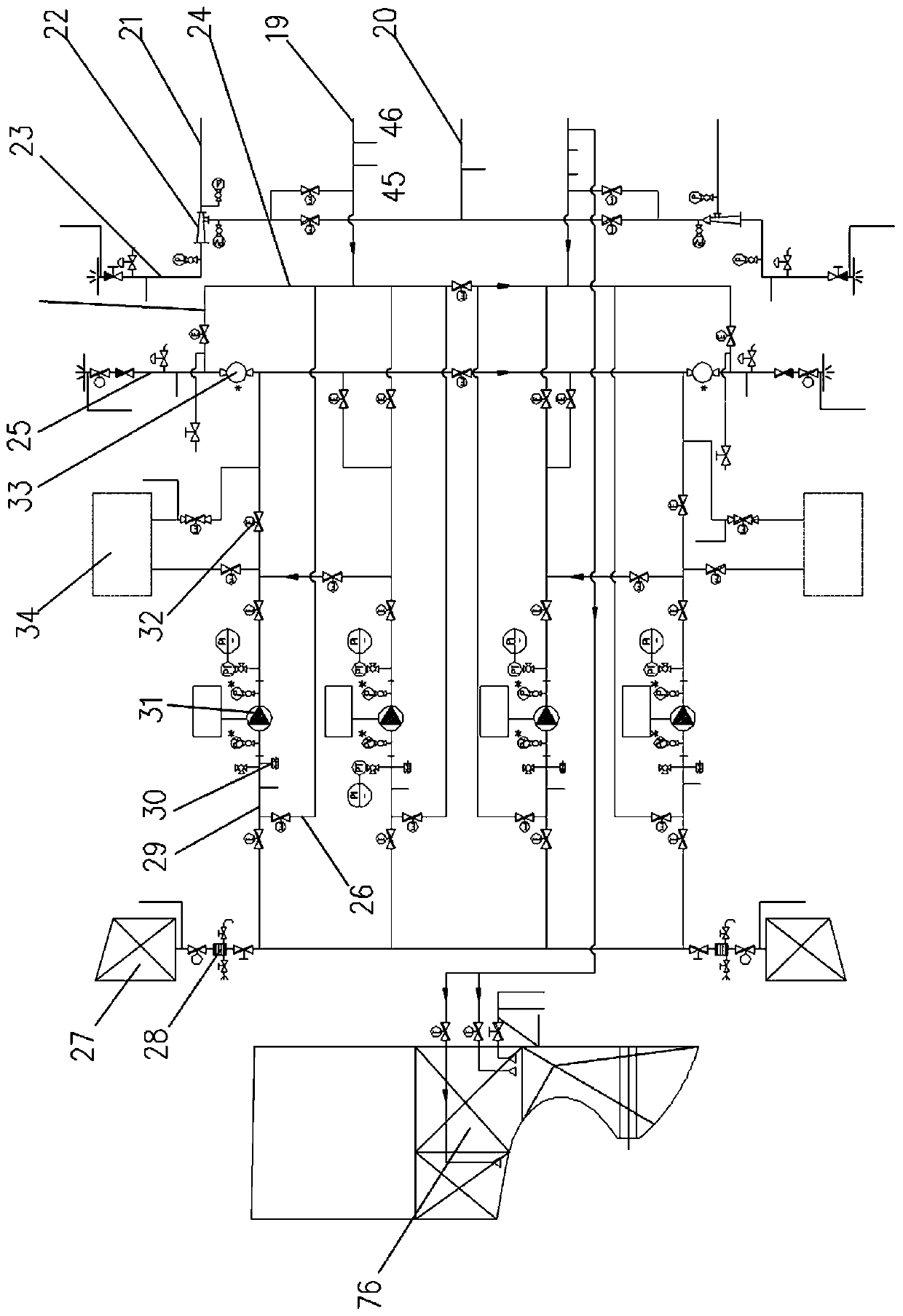

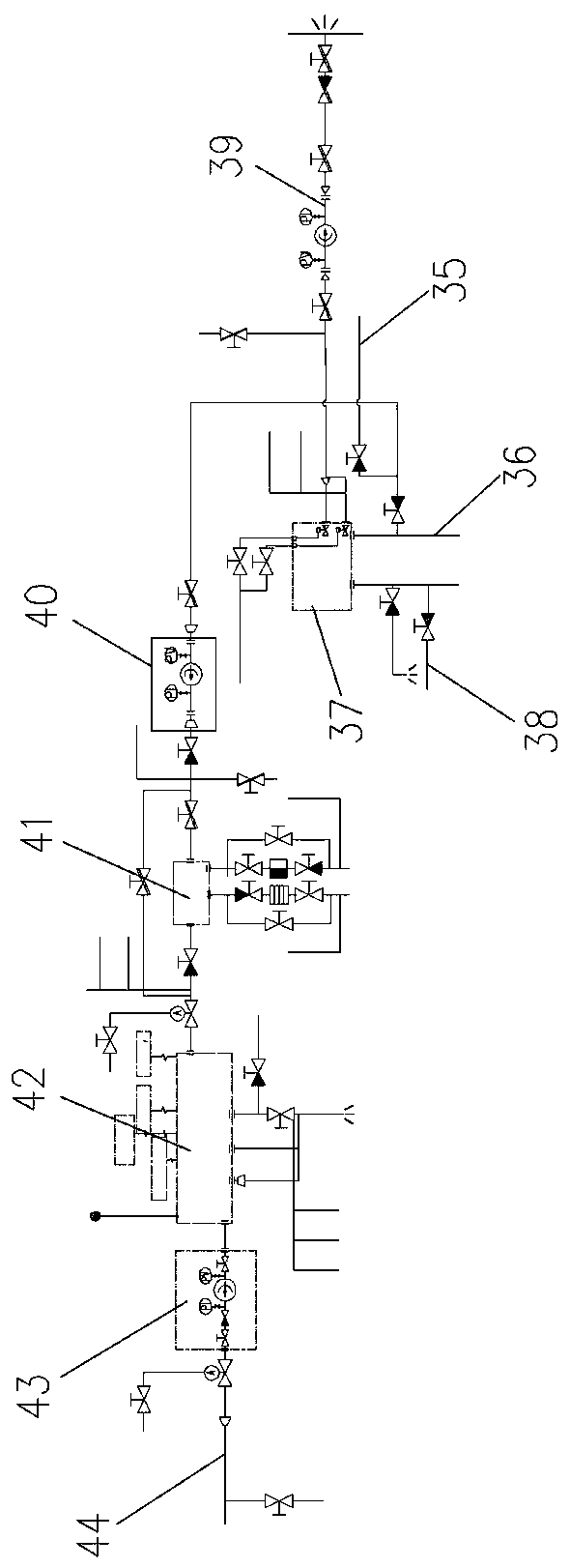

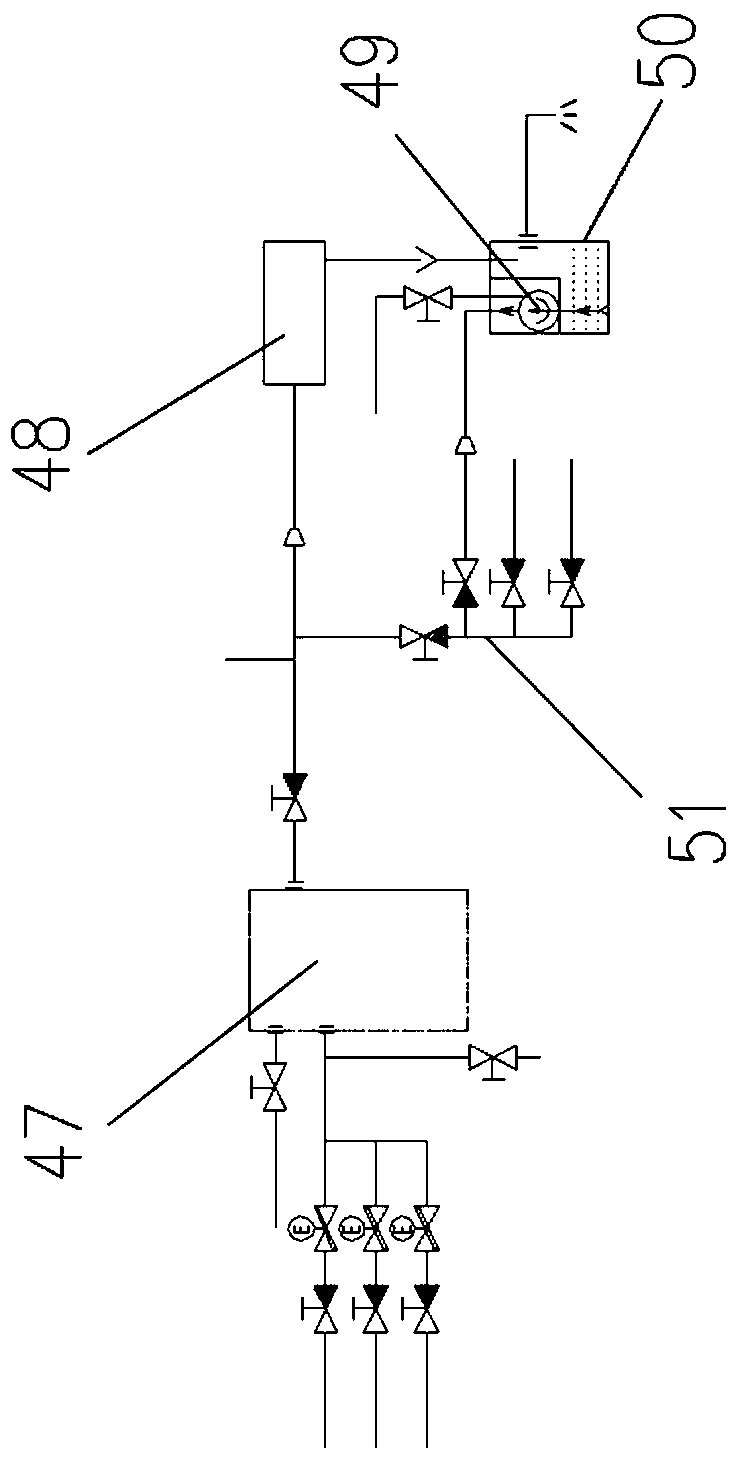

[0015] Figure 1-3 As shown, a green environmental protection ship ballast water treatment system, the ballast water treatment system includes a ballast water main pipe 19, a stripping water main pipe 20, a fire main pipe 21, a ballast stripping jet pump 22, a ballast stripping water discharge Pipe 23, electrolyzed water injection pipe 24, ballast water discharge pipe 25, ballast water injection pipe 26, ballast sea water tank 27, ballast injection filter 28, ballast self-suction pipe 29, ballast sampling liquid return port 30, Ballast self-priming pump 31, ballast filter switching valve 32, ballast discharge flowmeter 33, filter electrolysis device 34, electrolysis input pipe 35, ballast filter pipe 36, ballast filter 37, fresh water inlet pipe 38, filter Recoil discharge pipe 39, electrolysis booster pump 40, electrolysis steam heater 41, electrolysis un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com