Semiconductor anode material for hydrogen peroxide preparation by photoelectrocatalysis and preparation method thereof

A photoelectric catalysis and anode material technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of simple and easy preparation method, mild reaction conditions and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) TiO 2 Preparation of nanorod precursor solution

[0043] a) Add 20mL deionized water and 20mL concentrated hydrochloric acid (aqueous hydrogen chloride solution, the mass percentage of hydrogen chloride is 37%) into a beaker, and stir for 5min to prepare TiO 2 Nanorod precursor a solution;

[0044] b) on TiO 2 Add 0.65mL tetra-n-butyl titanate to the nanorod precursor a solution, and continue stirring for 5 minutes to obtain TiO 2 Nanorod precursor b solution.

[0045] c) on TiO 2 In the nanorod precursor b solution, add 3.35mL NaCl aqueous solution with a concentration of 5mol / L, and continue stirring for 5 minutes to obtain TiO 2 Nanorod precursor solution.

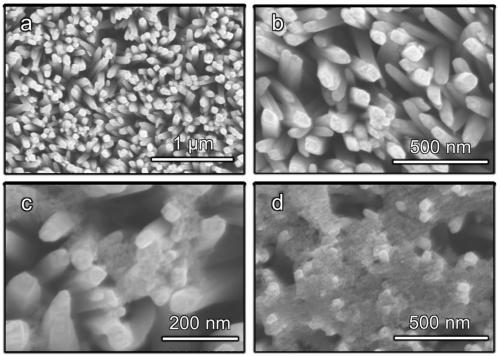

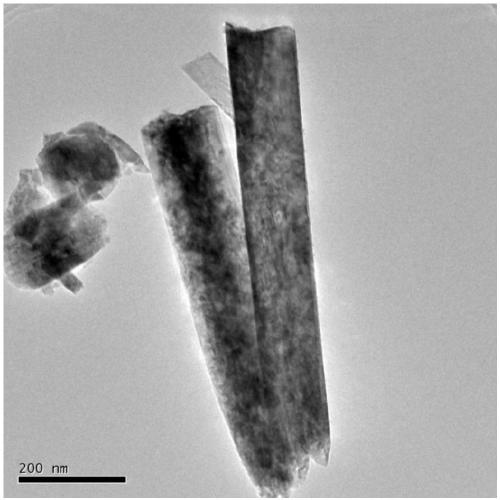

[0046] (2)TiO 2 Hydrothermal Growth of Nanorods

[0047] Add TiO to the hydrothermal kettle 2 Nanorod precursor solution and 5*1cm 2 The FTO conductive glass was hydrothermally grown at 150 °C for 10 h. The obtained sample was washed and fired at 500° C. for 2 hours (air atmosphere). Finally get T...

Embodiment 2

[0060] (1) TiO 2 Preparation of nanorod precursor solution

[0061] a) Add 20mL deionized water and 20mL concentrated hydrochloric acid into a beaker and stir for 5min to prepare TiO 2 Nanorod precursor a solution;

[0062] b) on TiO 2 Add 0.3mL tetra-n-butyl titanate to the nanorod precursor a solution, and continue stirring for 5 minutes to obtain TiO 2 Nanorod precursor b solution.

[0063] c) on TiO 2 In the nanorod precursor b solution, add 3.35mL NaCl solution with a concentration of 5mol / L, and continue stirring for 5 minutes to obtain TiO 2 Nanorod precursor solution.

[0064] (2)TiO 2 The hydrothermal growth of nanorods is the same as in Example 1.

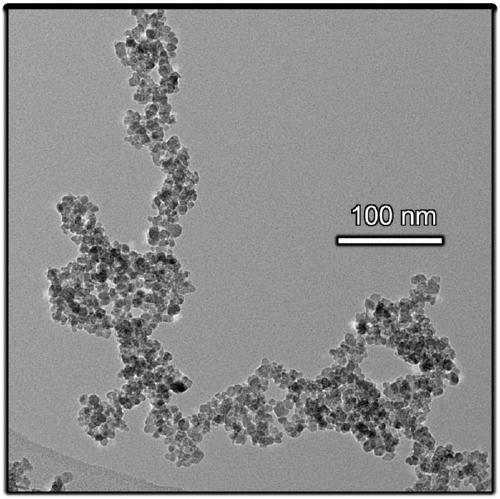

[0065] (3)Co 3 o 4 The preparation of nanoparticles is the same as in Example 1.

[0066] (4)Co 3 o 4 / TiO 2 The preparation of the composite photoanode material is the same as in Example 1.

[0067] TiO 2 The nanorod grows on the conductive surface of the FTO conductive glass, and its shape is in the shap...

Embodiment 3

[0073] (1) TiO 2 Preparation of nanorod precursor solution

[0074] a) Add 20mL deionized water and 20mL concentrated hydrochloric acid into a beaker and stir for 5min to prepare TiO 2 Nanorod precursor a solution;

[0075] b) on TiO 2 Add 1.0mL tetra-n-butyl titanate to the nanorod precursor a solution, and continue stirring for 5 minutes to obtain TiO 2 Nanorod precursor b solution.

[0076] c) on TiO 2 In the nanorod precursor b solution, add 3.35mL NaCl solution with a concentration of 5mol / L, and continue stirring for 5 minutes to obtain TiO 2 Nanorod precursor solution.

[0077] (2)TiO 2 The hydrothermal growth of nanorods is the same as in Example 1.

[0078] (3)Co 3 o 4 The preparation of nanoparticles is the same as in Example 1.

[0079] (4)Co 3 o 4 / TiO 2 The preparation of the composite photoanode material is the same as in Example 1.

[0080] TiO 2 The nanorod grows on the conductive surface of the FTO conductive glass, and its shape is in the shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com