Wear-resistant and cigarette-firing-resistant melamine impregnated paper and preparation method thereof

A first melamine and melamine technology, applied in paper, papermaking, paper coating and other directions, can solve the problem of yellowing of plain color base paper or printing decorative paper, poor resistance to cigarette burning, poor thermal insulation ability of urea-formaldehyde resin layer, etc. problems, to achieve the effect of low production cost, excellent resistance to cigarette burning, and avoiding high temperature yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

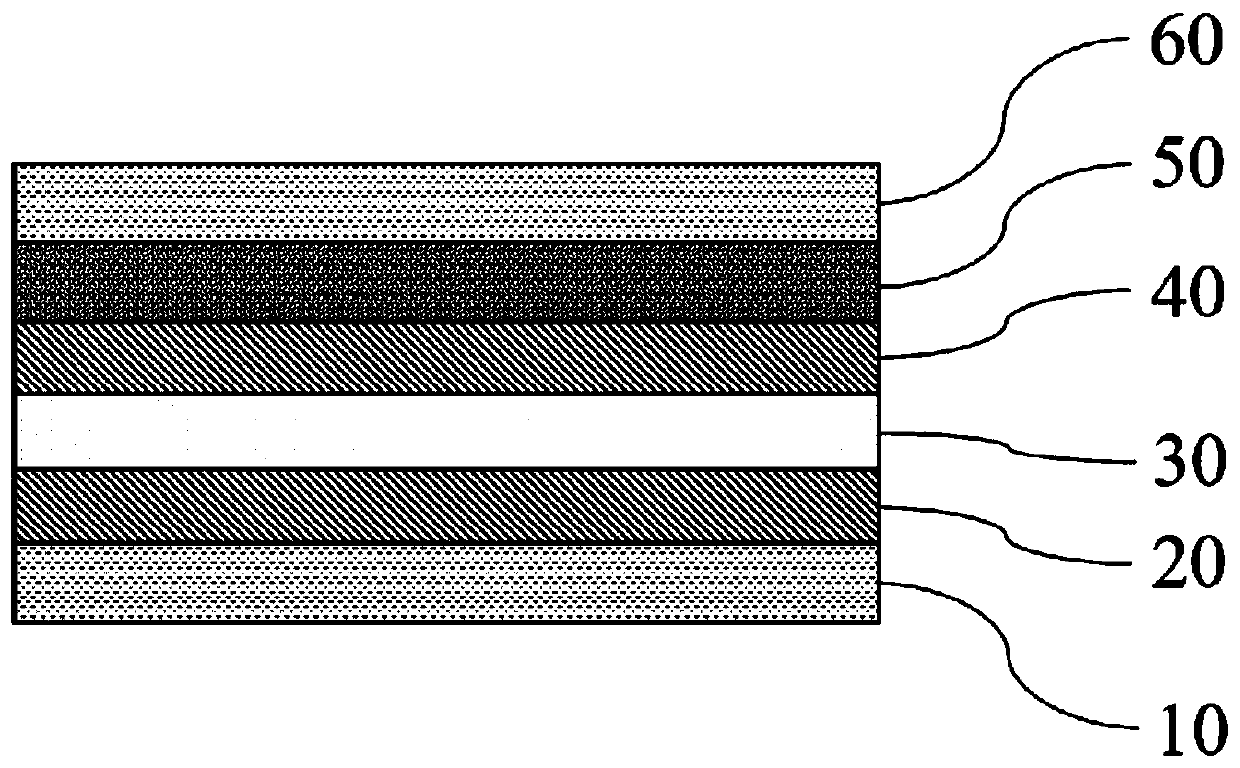

[0043] A kind of wear-resistant cigarette burning melamine impregnated paper (structural schematic diagram as figure 1 shown), including the first melamine resin layer (thickness 150 μm), the first urea-formaldehyde resin layer (thickness 200 μm), printed decorative paper (gram weight 80 g / m) arranged in sequence from bottom to top 2 ), the second urea-formaldehyde resin layer (thickness 200 μm), heat-insulating and wear-resistant melamine resin layer (thickness 80 μm) and the second melamine resin layer (thickness 120 μm).

[0044] The preparation method of the above-mentioned wear-resistant and cigarette-burning-resistant melamine-impregnated paper comprises the following steps:

[0045] 1) Add 350 parts by mass of formaldehyde solution (mass fraction 37%), 90 parts by mass of urea and 3 parts by mass of urotropine into the reaction kettle, heat up to 90°C for 30 minutes, then keep warm at 90-95°C for 60 minutes, and test the resin Whether there is an atomization point in w...

Embodiment 2

[0059] A kind of wear-resistant cigarette burning melamine impregnated paper (structural schematic diagram as figure 1 shown), including the first melamine resin layer (thickness 150 μm), the first urea-formaldehyde resin layer (thickness 240 μm), printed decorative paper (gram weight 90 g / m) arranged in sequence from bottom to top 2 ), a second urea-formaldehyde resin layer (thickness 240 μm), heat-insulating and wear-resistant melamine resin layer (thickness 50 μm) and a second melamine resin layer (thickness 150 μm).

[0060] The preparation method of the above-mentioned wear-resistant and cigarette-burning-resistant melamine-impregnated paper comprises the following steps:

[0061] 1) Add 350 parts by mass of formaldehyde solution (mass fraction 37%), 90 parts by mass of urea and 3 parts by mass of urotropine into the reaction kettle, heat up to 90°C for 30 minutes, then keep warm at 90-95°C for 60 minutes, and test the resin Whether there is an atomization point in water...

Embodiment 3

[0072] A kind of wear-resistant cigarette burning melamine impregnated paper (structural schematic diagram as figure 1 shown), including the first melamine resin layer (thickness 160 μm), the first urea-formaldehyde resin layer (thickness 270 μm), plain base paper, the second urea-formaldehyde resin layer (thickness 270 μm), thermal insulation and wear-resistant A melamine resin layer (thickness 90 μm) and a second melamine resin layer (thickness 130 μm).

[0073] The preparation method of the above-mentioned wear-resistant and cigarette-burning-resistant melamine-impregnated paper comprises the following steps:

[0074] 1) Add 350 parts by mass of formaldehyde solution (mass fraction 37%), 90 parts by mass of urea and 3 parts by mass of urotropine into the reaction kettle, heat up to 90°C for 30 minutes, then keep warm at 90-95°C for 60 minutes, and test the resin Whether there is an atomization point in water at 10°C, until the atomization point appears at 32°C, then add 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com