Device and method for manufacturing non-diagenetic hydrate siltstone core

A technology for making devices and hydrates, which is applied in the preparation of test samples, etc., and can solve problems such as refractory hydrate cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method aims at making a hydrate-containing siltstone core with a diameter of 25 mm and a height of 50 mm for quartz sand with a small size range and a particle size larger than 250 mesh and smaller than 1500 mesh. The method is now described in detail.

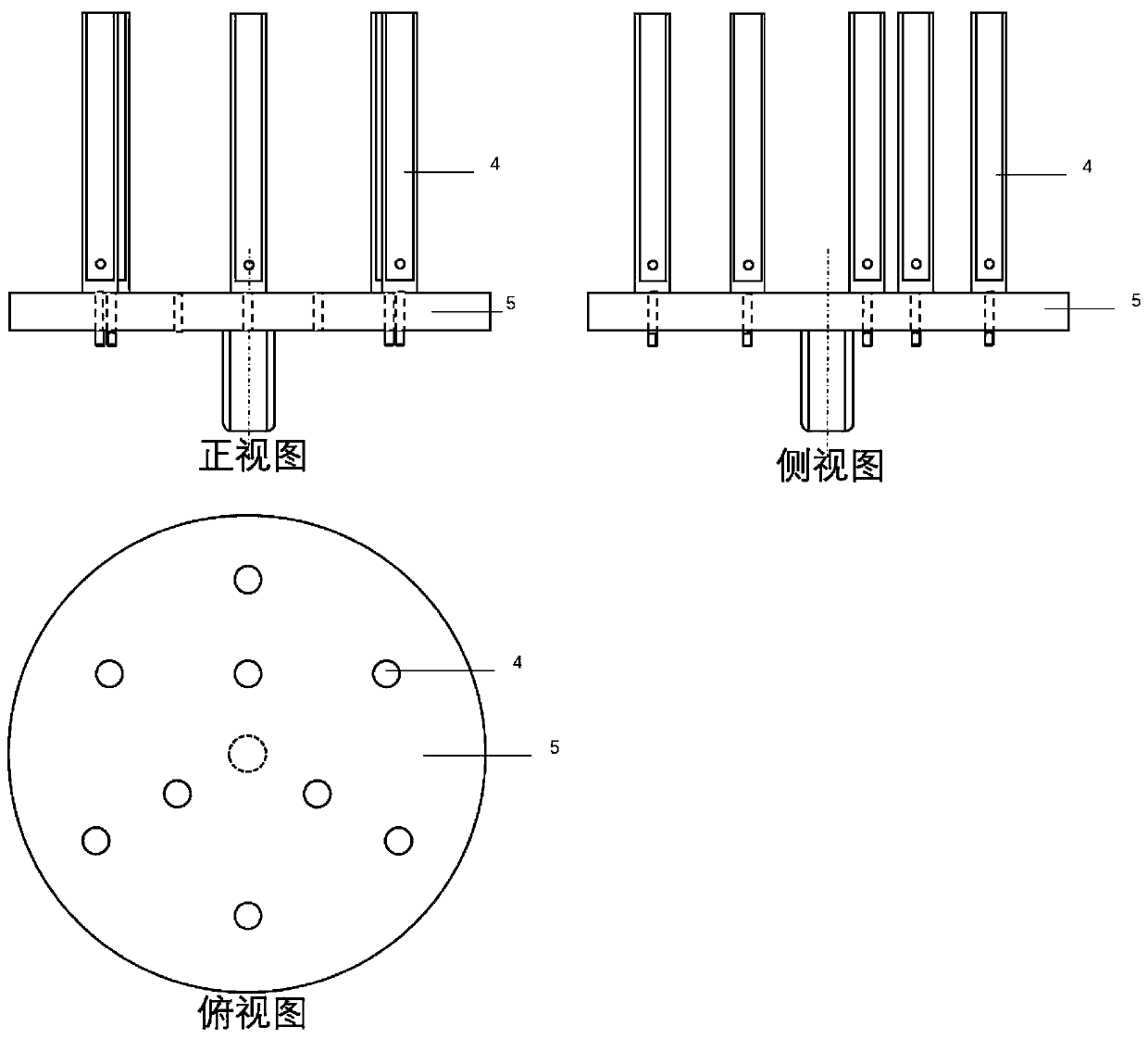

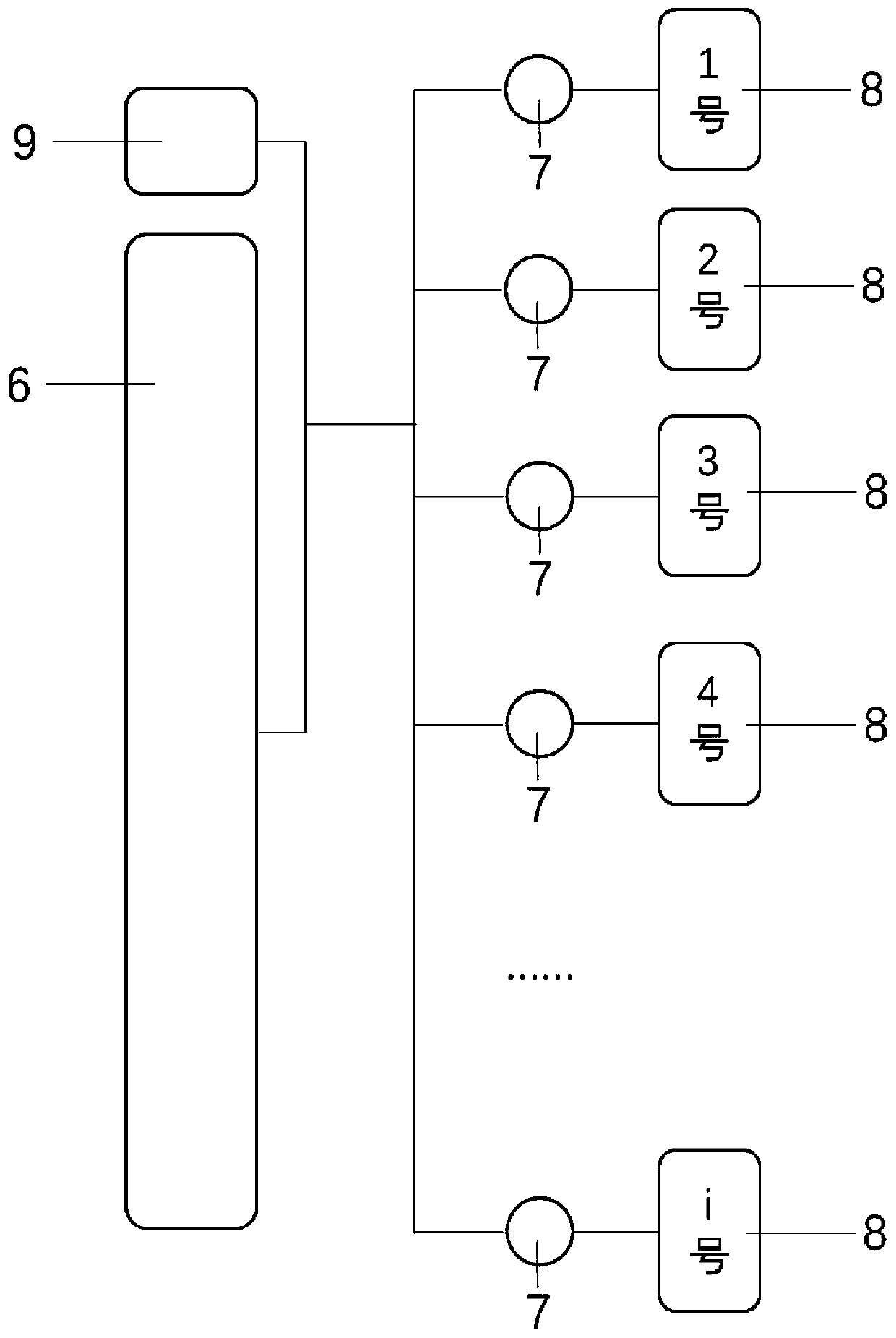

[0019] Step 1: Assemble the detachable particle sedimentation device and add materials to it. The specific steps are:

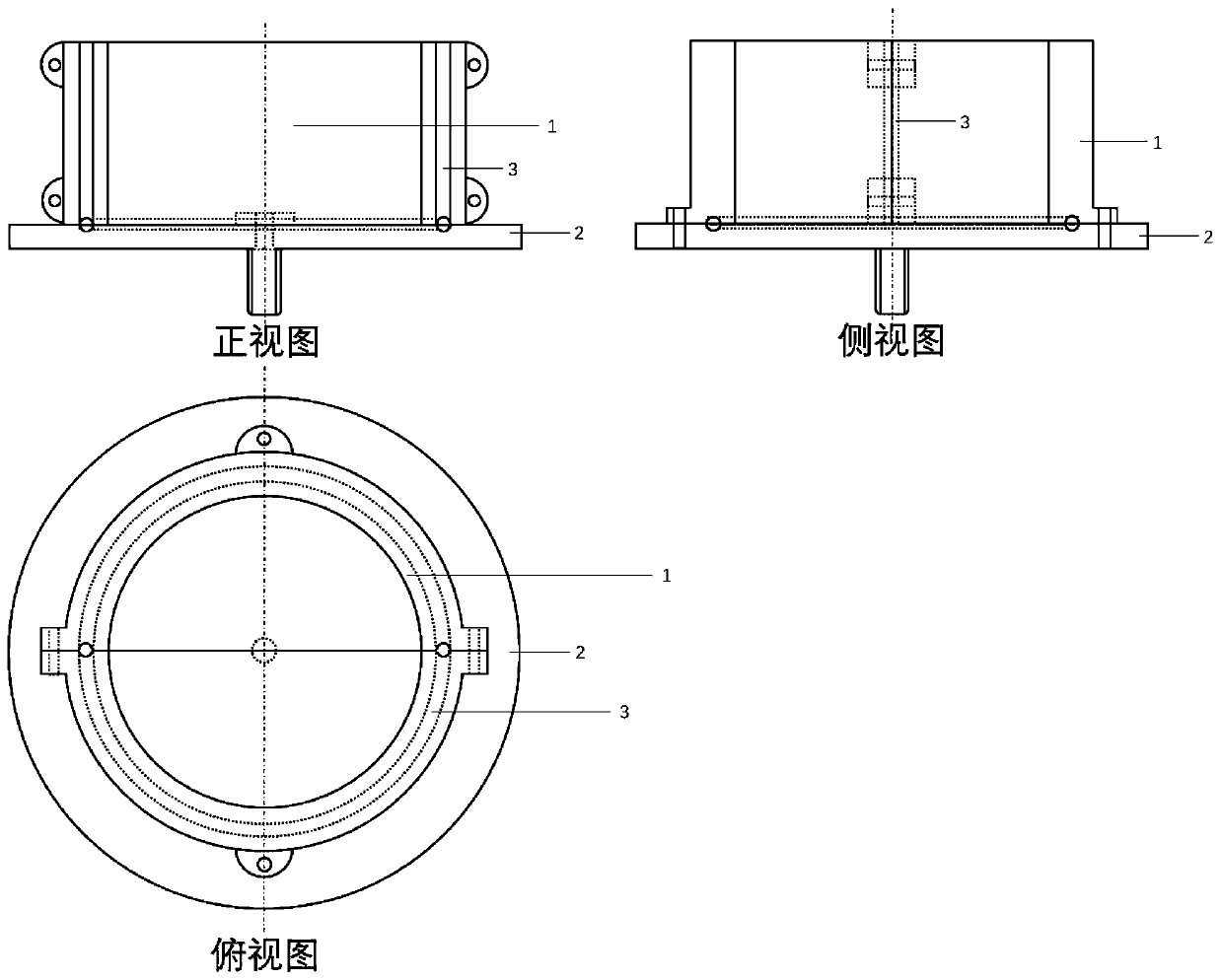

[0020] (1) Fill the sealing silicone strip 3 into the cylindrical groove spliced by the two semicircular grooved cylinders as shown in the figure and the lower semicircular and semi-annular groove, and align the lower ring part of the sealing silicone strip 3 and the downward fixing base 2 The semi-circular and semi-annular grooves are spliced on the fixed base 2.

[0021] (2) Utilize the bolt to pass through the horizontal fixing hole on the semicircle grooved cylinder 1, then fasten with nuts, so that the two semicircle grooved cylinders 1 are fastened, and utilize the bolt to pass through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com