Date printing accuracy detection method and system based on two-dimensional code

A detection method and detection system technology, which are applied in manufacturing computing systems, digital output to printing units, input/output processes of data processing, etc. problems, to achieve the effect of reducing costs and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

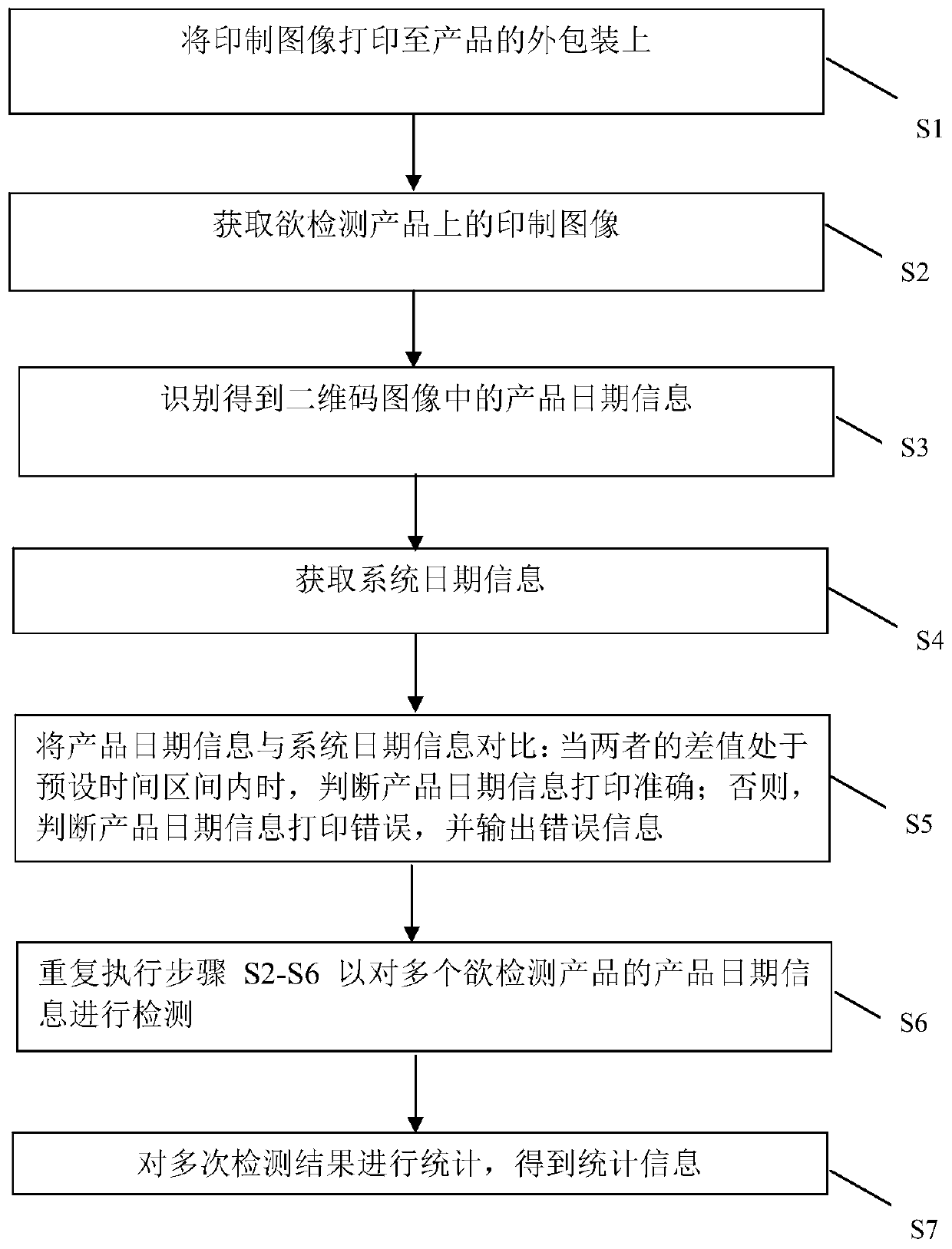

[0064] Such as figure 1 As shown, this embodiment 1 discloses a date printing accuracy detection method based on a two-dimensional code, comprising the following steps:

[0065] S1. Print the printed image on the outer packaging of the product;

[0066] Specifically, the printed image includes a QR code image and product date;

[0067] Specifically, the printing can be realized by using a printing device such as a laser printer or an inkjet printer;

[0068] Specifically, step S1 includes:

[0069] S11. Obtain the system date of the printing device to set it as the product date;

[0070] S12, encoding the product date into a two-dimensional code image;

[0071] S13. Combining the product date and the two-dimensional code image into a printed image;

[0072] S14. Send the printed image to a printing device to be printed on the product.

[0073] The above steps print the system date and the QR code image on the product at the same time, so that when judging the printing er...

Embodiment 2

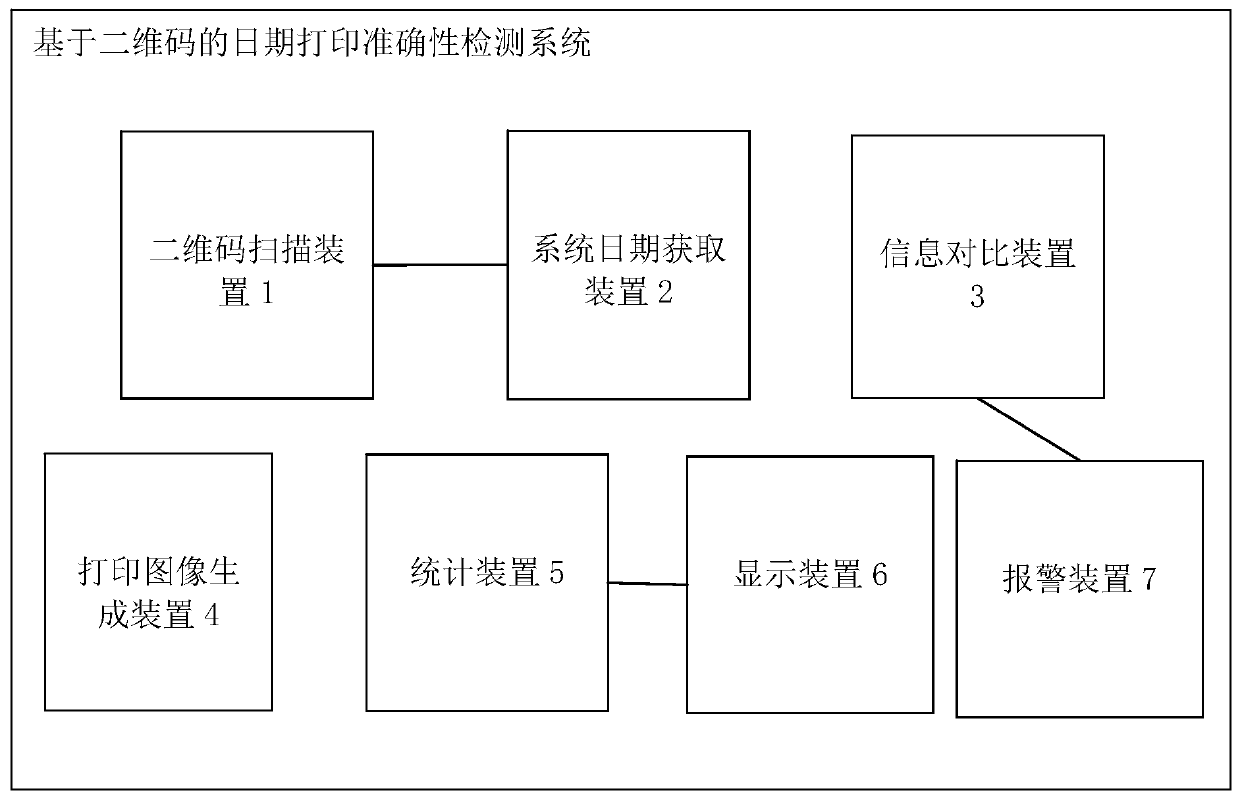

[0094] Such as figure 2 As shown, this embodiment corresponds to the two-dimensional code-based date printing accuracy detection method in Embodiment 1, and discloses a two-dimensional code-based date printing accuracy detection system, including:

[0095] The two-dimensional code scanning device 1 is used to obtain the printed image including the two-dimensional code image and the product date on the product to be detected, and identify the product date information in the two-dimensional code image;

[0096] A system date obtaining device 2, connected to the two-dimensional code scanning device 1, for obtaining system date information;

[0097] Specifically, the system date acquisition device 2 includes:

[0098] The calibration module 21 is connected to the printing device, and is used to network the system date information of the two-dimensional code scanning device and the system date of the printing device for regular calibration;

[0099] Date acquisition module 22, u...

Embodiment 3

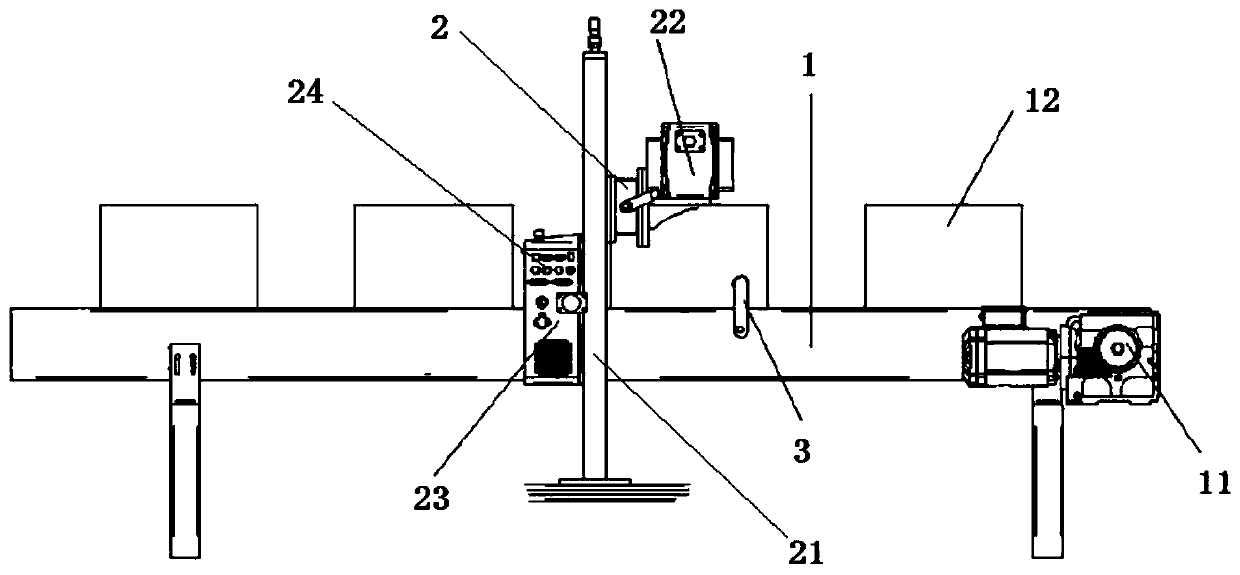

[0118] Such as image 3 As shown, this embodiment corresponds to the technical solutions disclosed in Embodiment 1 and Embodiment 2, and discloses a beer packaging box date printing accuracy detection system, which includes a two-dimensional code scanning device 2 arranged on one side of the conveyor belt 1 And the photoelectric sensor 3, the conveyor belt 1 is driven by the motor 11 to transmit the beer packaging box 12;

[0119] Specifically, the laser printing on the beer packaging box 12 is like Figure 4 The image shown includes the two-dimensional code and the production date; the coding format in the two-dimensional code is shown in the table below, including production information such as the production date, manufacturer, and production line number;

[0120]

[0121] Among them: the first three codes are fixed according to the place of production, production line number and lane location, the middle five codes record information such as year, month, day, hour and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com