A preparation method of antimony sulfide nanorod negative electrode for lithium ion battery

A lithium-ion battery and antimony sulfide technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of high production cost and low specific capacity, achieve good cycle performance, good rate performance, and broaden the effect of industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

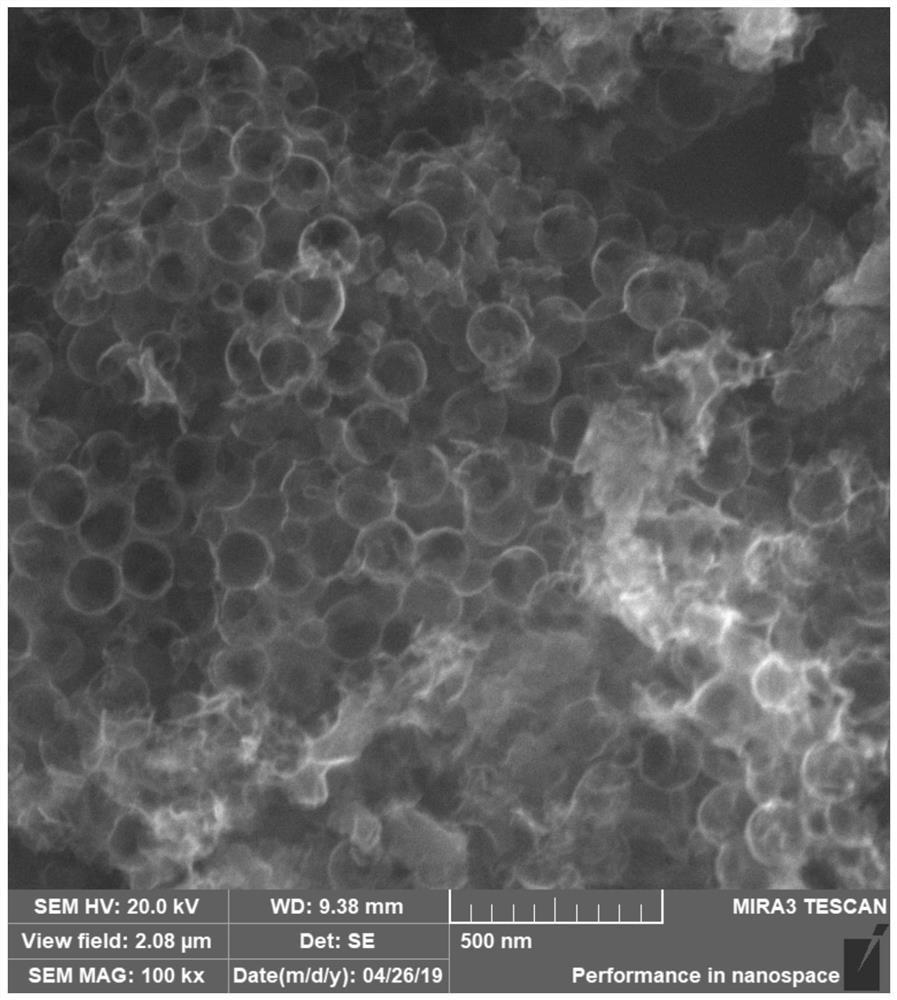

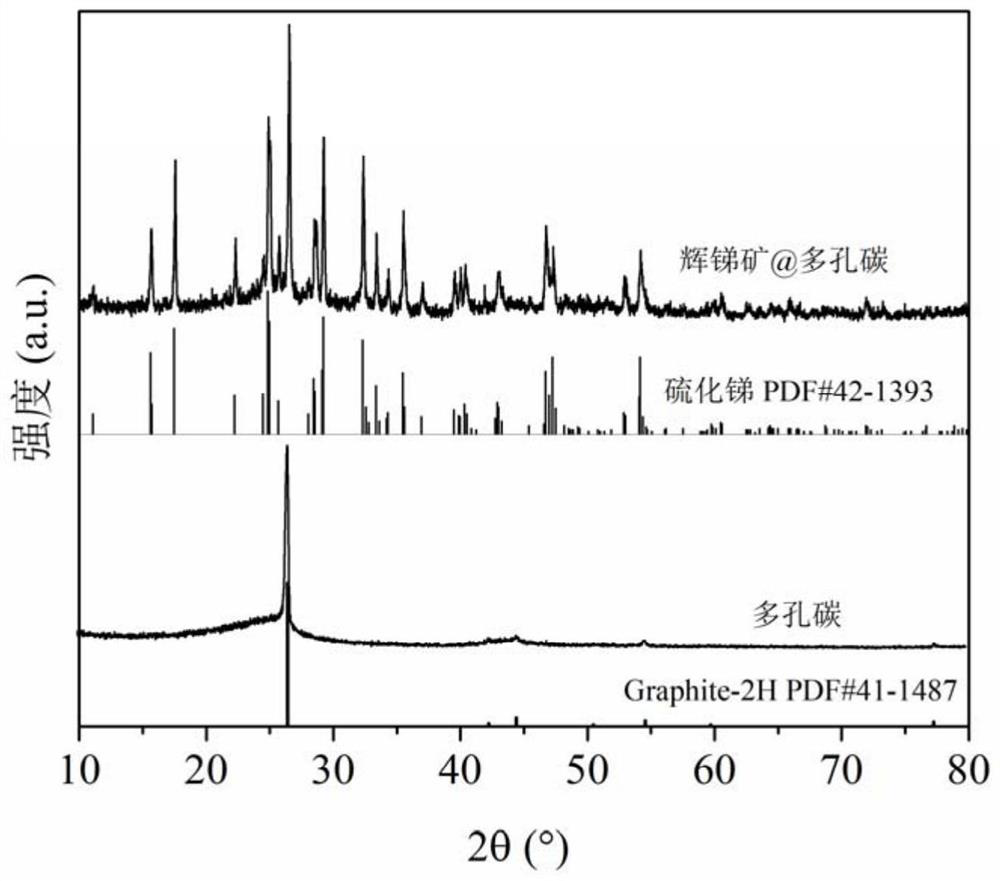

[0026] Weigh stibnite and mesoporous carbon according to the mass ratio of 1:1, add them to the ball mill tank, add ball mill beads according to the ball-to-material ratio of 10:1, and add alcohol according to the mass ratio of ball mill material to alcohol of 5:1, and use 450r / min for ball milling, the ball milling time is 4h. The resulting mixture was filtered, dried and ground. figure 1 A scanning electron microscope picture of the porous carbon used is shown, and it can be seen that the porous carbon has a pore size of about 150 nm and a pore wall thickness of 6 nm.

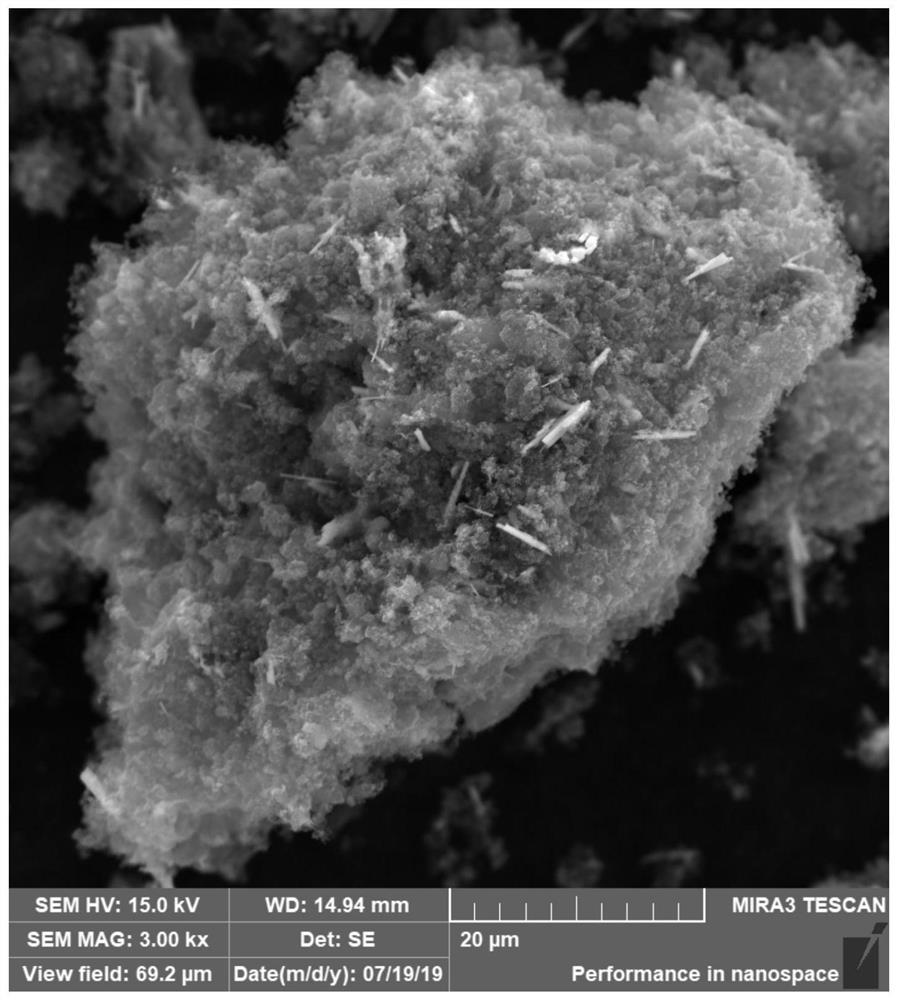

[0027] The ball mill mixture was placed in a heating furnace, argon gas was introduced, the temperature was raised to 600° C. at a rate of 5° C. / min, and the temperature was kept for 5 hours. After natural cooling, take it out to obtain a porous carbon-coated stibnite nanorod negative electrode, such as figure 2 shown. From figure 2 It can be seen that the diameter of the recombined stibnite nanorods i...

Embodiment 2

[0030] Weigh high-purity antimony sulfide and microporous carbon at a mass ratio of 85:15, add them to a ball mill tank, add ball milling beads at a ball-to-material ratio of 15:1, and perform ball milling at 600r / min in an air medium for 1 hour. The resulting mixture was filtered, dried and ground.

[0031] The ball mill mixture was placed in a heating furnace, argon gas was introduced, the temperature was raised to 600°C at a rate of 1°C / min, and the temperature was kept for 10 hours. After natural cooling, take it out to obtain a porous carbon-coated stibnite nanorod negative electrode.

Embodiment 3

[0033] Weigh the stibnite and macroporous carbon material according to the mass ratio of 20:80, add them to the ball milling tank, add ball milling beads according to the ball-to-material ratio of 20:1, and perform ball milling in an argon medium at 400r / min for 5 hours . The resulting mixture was filtered, dried and ground.

[0034] The ball mill mixture was placed in a heating furnace, and argon gas was introduced, and the temperature was raised to 650° C. at a rate of 10° C. / min, and kept for 5 hours. After natural cooling, take it out to obtain a porous carbon-coated stibnite nanorod negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com