Water Cooling in Vertical Forced Circulation Steam Generators

A technology of steam generator and forced circulation, applied in steam generation, forced flow steam boilers, steam boilers, etc., can solve problems such as high water consumption, and achieve the effect of reducing water consumption and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

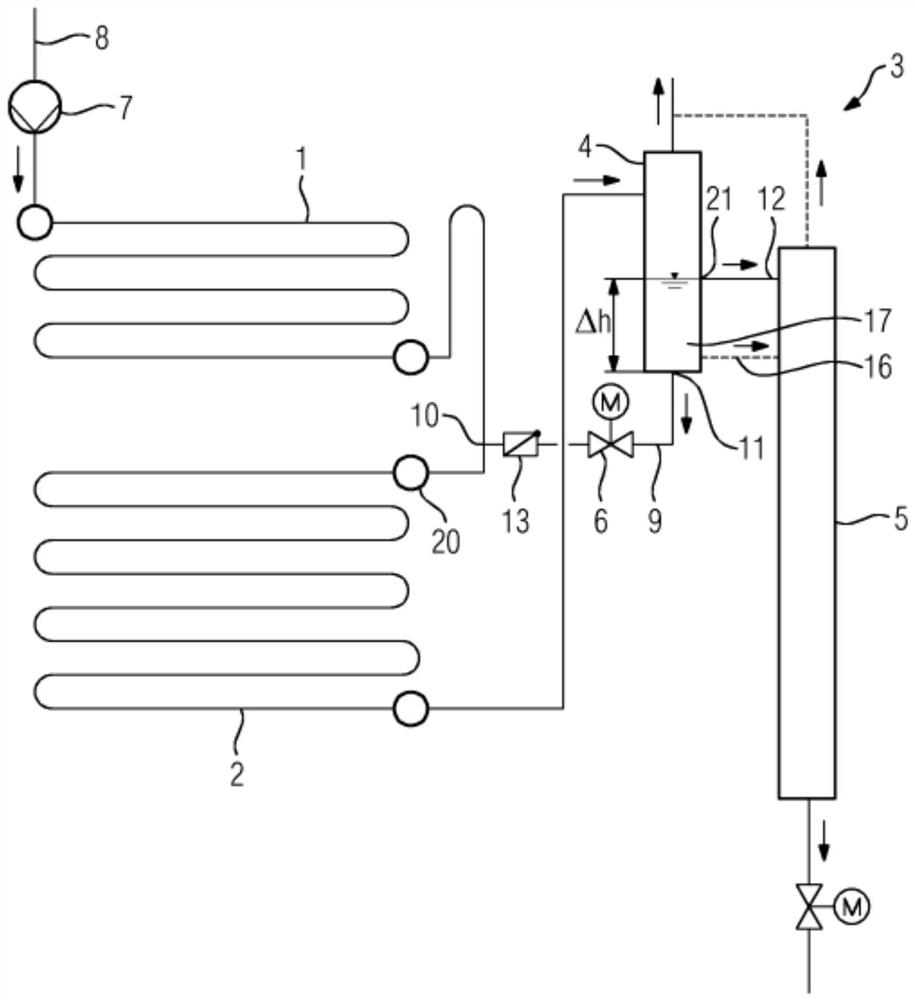

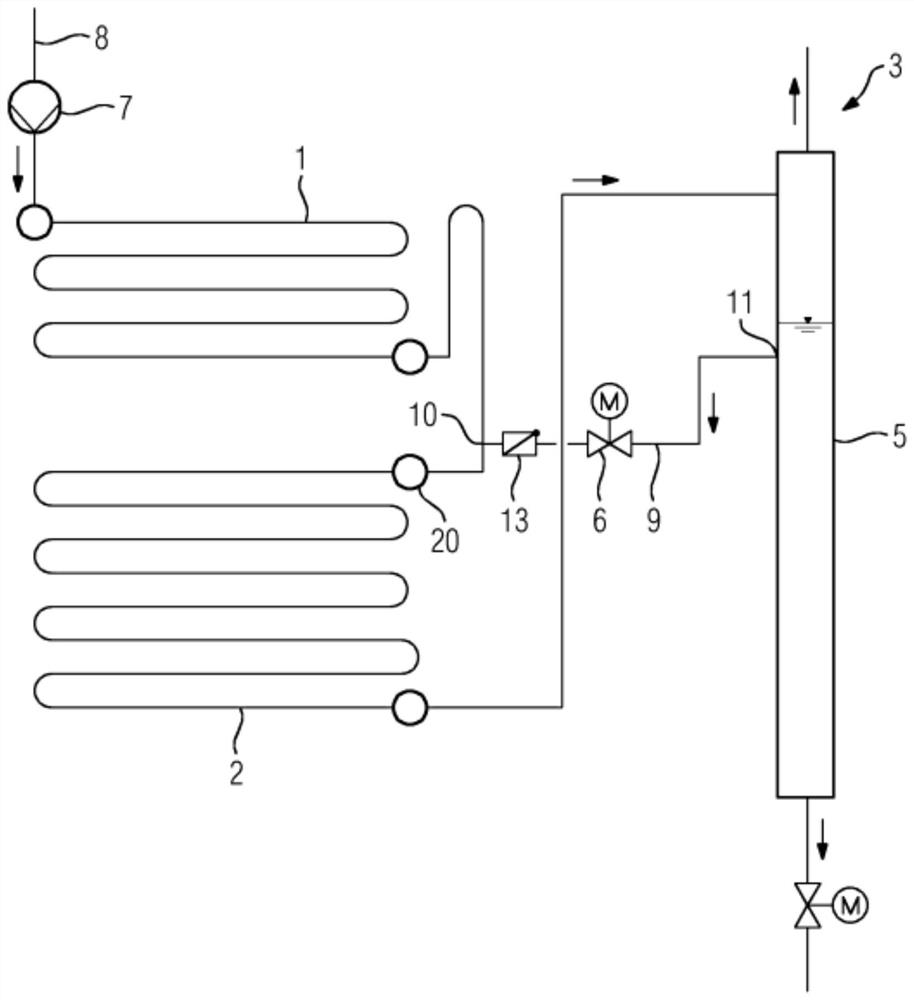

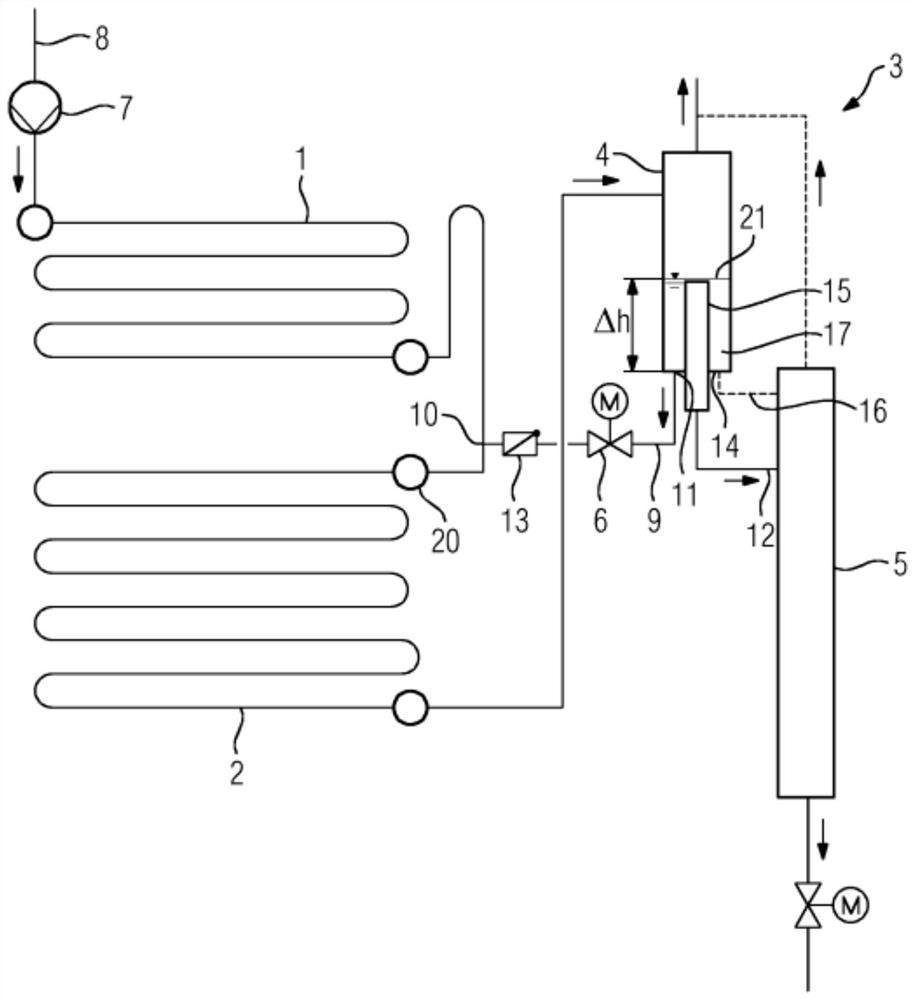

[0023] figure 1 Schematically and exemplarily shown a device for starting a vertical forced circulation steam generator with a feed water preheater 1 , by means of a feed water pump 7 via a feed water delivery line 8 , feed water can be supplied as working fluid to the feed water preheater; and evaporator 2; and water separation system 3. All that is required to implement the device according to the invention is to separate the separator 4 from the water bottle 5 in the water separation system 3 . exist figure 2 A technically less advantageous solution with a common container for separator and bottle is shown in .

[0024] exist figure 1 In an embodiment of the present invention, the lower end 17 of the separator 4 is clearly higher than the joining point 10 in the evaporator 2 , for example higher than the inflow collector 20 . A short outflow from the separator 4 to the evaporator 2 is thus made possible. The outflow takes place from the working medium outlet 11 via th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com