Ruling machine and PC component production system

A scribing machine and component technology, applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of low scribing accuracy, inaccurate placement of molds by workers, and inability to form thin lines, etc., and achieve long shelf life , Guarantee marking accuracy and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

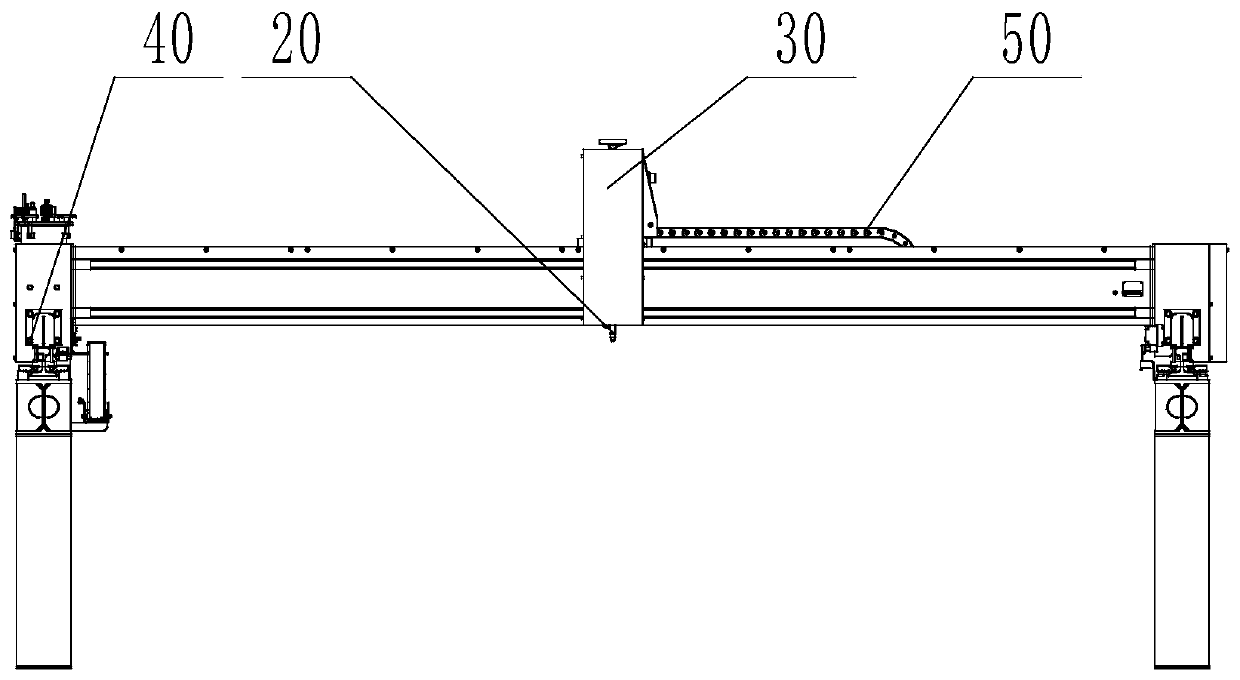

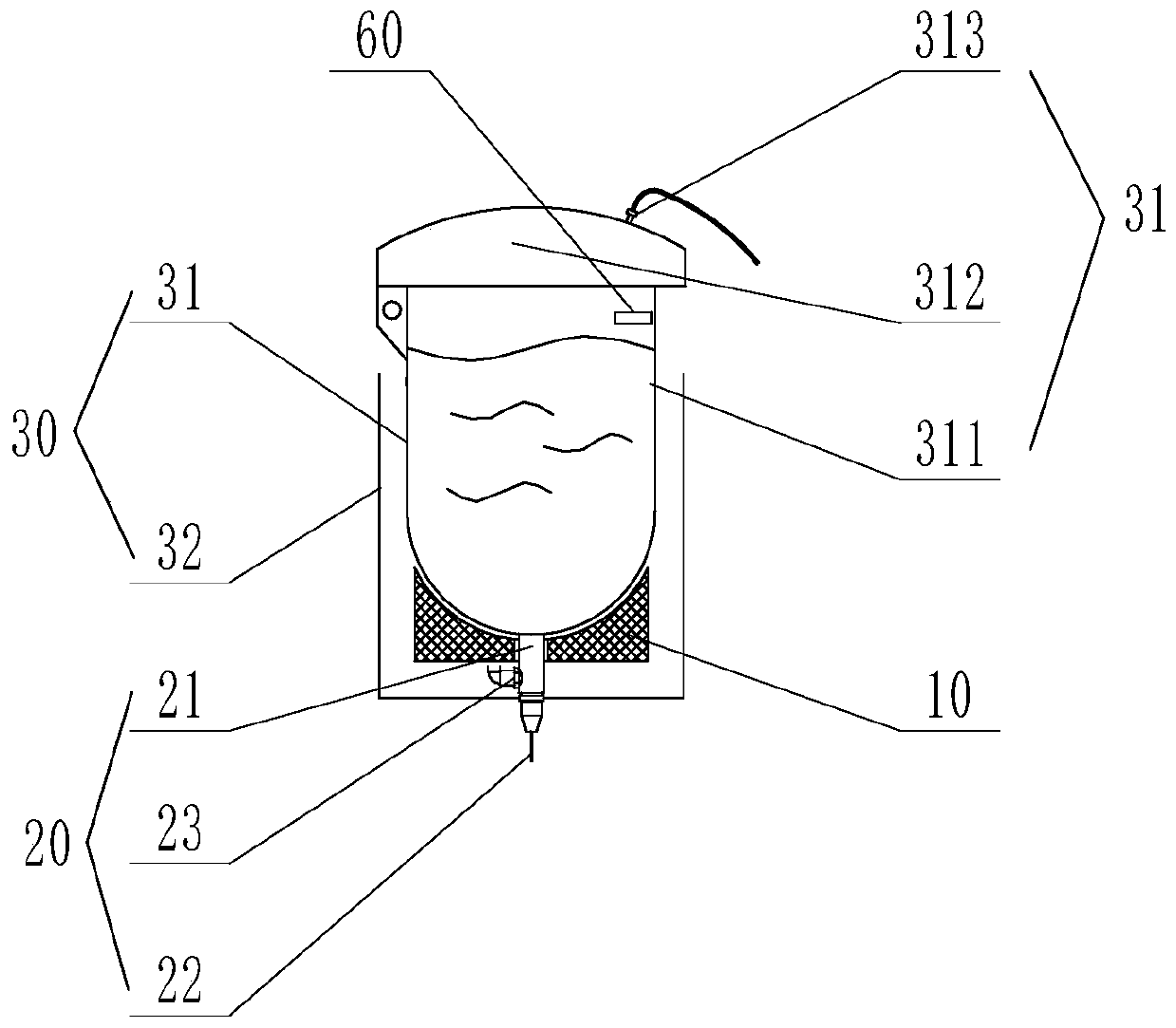

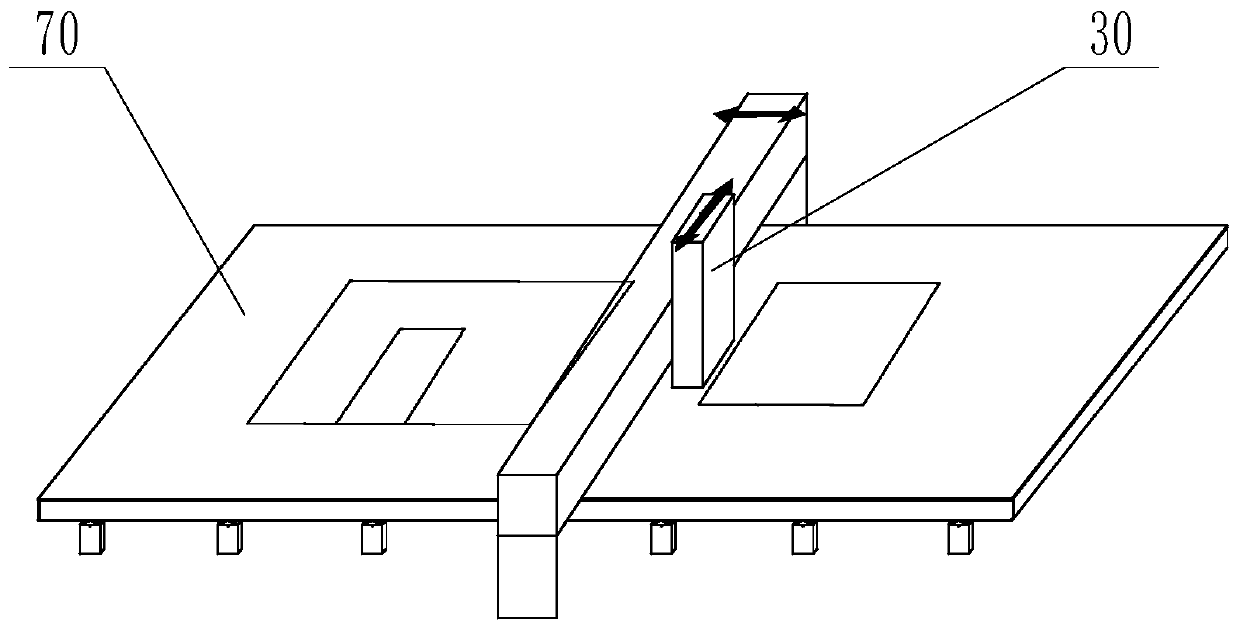

[0028] Such as Figure 1 to Figure 3 As shown, the present invention provides a marking machine, including a heating assembly 10, a storage assembly 30 and a paint head 20; the storage assembly 30 is used to store hot-melt paint raw materials, and the heating assembly 10 is used to heat and melt the hot-melt paint The raw material, the coating head 20 communicates with the material storage assembly 30, and the coating head 20 is used to coat the molten raw material on the surface of the mold table.

[0029] In the process of using the scribing machine provided by this embodiment, the corresponding hot-melt paint is used for scribing, and the heating assembly 10, the material storage assembly 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com