Wear-resistant aging-resistant power cable sheath material and preparation method thereof

A technology for power cables and sheath materials, applied in the field of wear-resistant and aging-resistant power cable sheath materials and its preparation, can solve problems such as strong adhesion, poor low temperature resistance, and potential safety hazards of cables, and achieve improved wear resistance and aging resistance The performance, wear resistance and heat resistance are improved, and the effect of ensuring the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

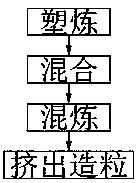

[0027] The preparation method of the wear-resistant and aging-resistant power cable sheath material comprises the following steps:

[0028] S1: Masticating: put silicone rubber, nitrile rubber and EPDM rubber into the internal mixer for masticating, the masticating temperature is 120°C-150°C, and the masticating time is 25-30 minutes to obtain masticated Gum;

[0029] S2: Mixing: Put the coupling agent, reinforcing agent and insect repellant into a high-speed mixer and mix them at the same time. The speed of the mixer is 300 rpm, and the mixing time is 25-30 minutes to prepare the rubber auxiliary agent;

[0030] S3: Mixing: put the plasticized rubber and vulcanizing agent into the internal mixer for mixing, and mix at a temperature of 175°C for 25 minutes, then add glass fibers and mix at a temperature of 125°C for 35 minutes, and then Add rubber auxiliary agent and knead for 20 minutes at a temperature of 75°C to obtain rubber with wear resistance, aging resistance and inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com