Foundation structure and foundation reconstruction method for backfilling mine pit with interlayer of engineering mud and slag

A technology for engineering slag and mud, which is applied in filling, infrastructure engineering, soil protection and other directions, can solve the problems affecting the construction progress of backfilling, affecting the terrain slope of reclaimed land, and dealing with difficult mud layers, so as to solve the problem of backfilling projects. Safety problems, eliminating hidden dangers of geological disasters, and realizing the effect of drainage consolidation and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

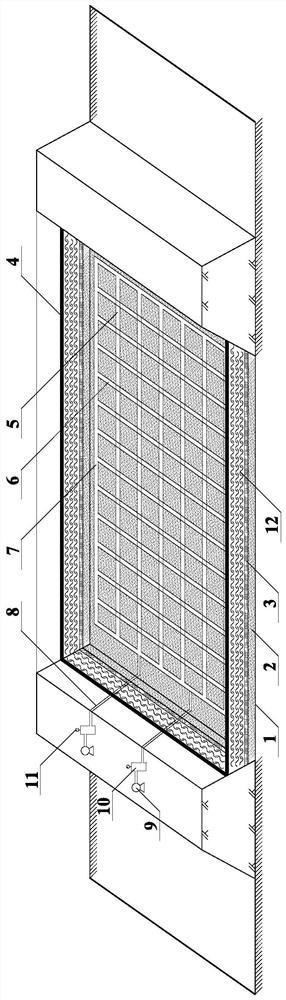

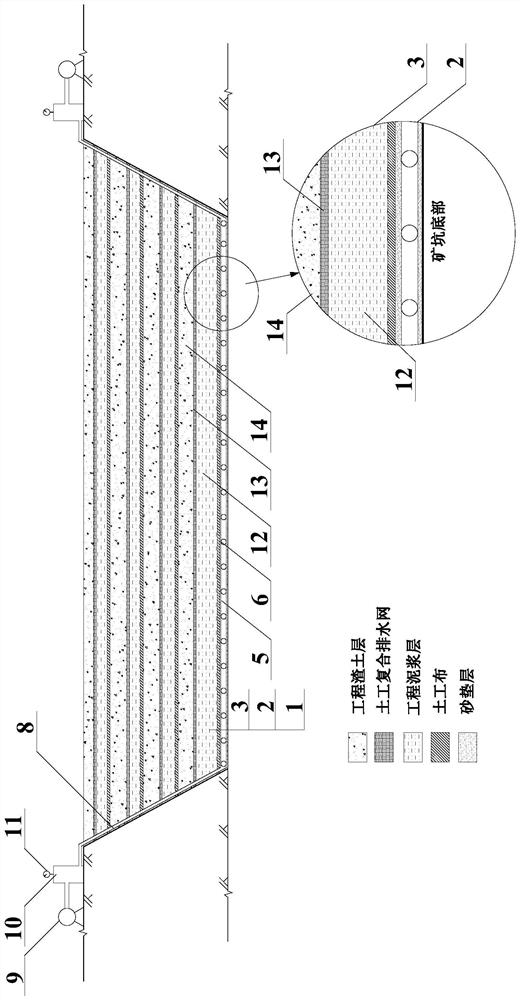

[0049] Such as figure 2 Shown, the specific embodiment of the inventive method is as follows:

[0050] 1) In the abandoned open-pit pits produced by mining mineral resources, level the bottom of the abandoned mine pit 1 site, remove the residual waste ore on the site, and push the site to level; if the site is difficult to level, it can be treated by laying a gravel layer or a sand cushion , so that the bottom surface of the abandoned mine pit 1 is a smooth plane;

[0051] 2) Lay the sand cushion layer 2 on the bottom surface of the mine pit first, and then lay a layer of vacuum filter pipe network on the sand cushion layer 2. The vacuum filter pipe network is composed of multiple parallel horizontal vacuum filter tubes 5 and multiple parallel longitudinal vacuum The pipe network structure formed by laying the filter tubes 6 vertically crosses, that is, the horizontal vacuum filter tubes 5 and the vertical vacuum filter tubes 6 are arranged in a cross, connected by four-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com