Fuel cell membrane electrode frame laminating device and method

A technology for fuel cell membranes and bonding devices, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve problems such as easy formation of air bubbles and defective products during the bonding process, so as to save CCM costs, reduce bonding areas, and reduce retention The effect of white areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

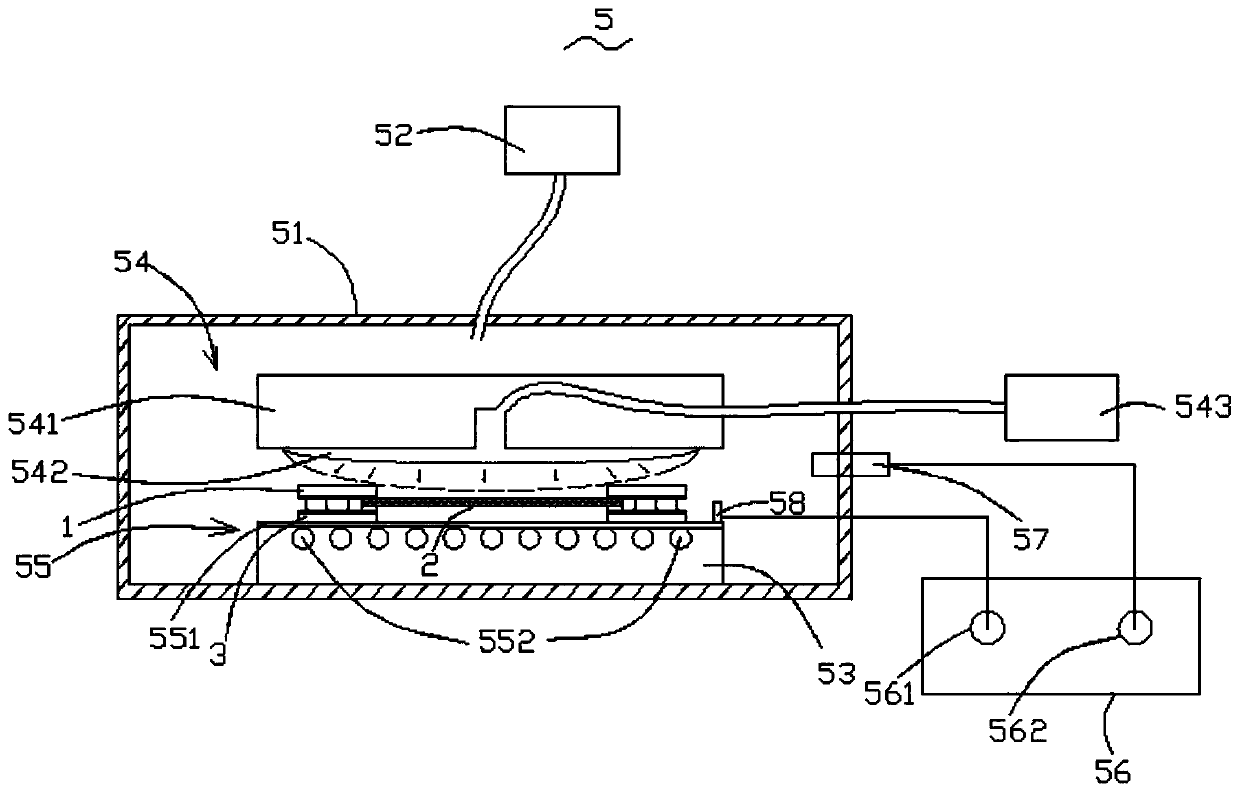

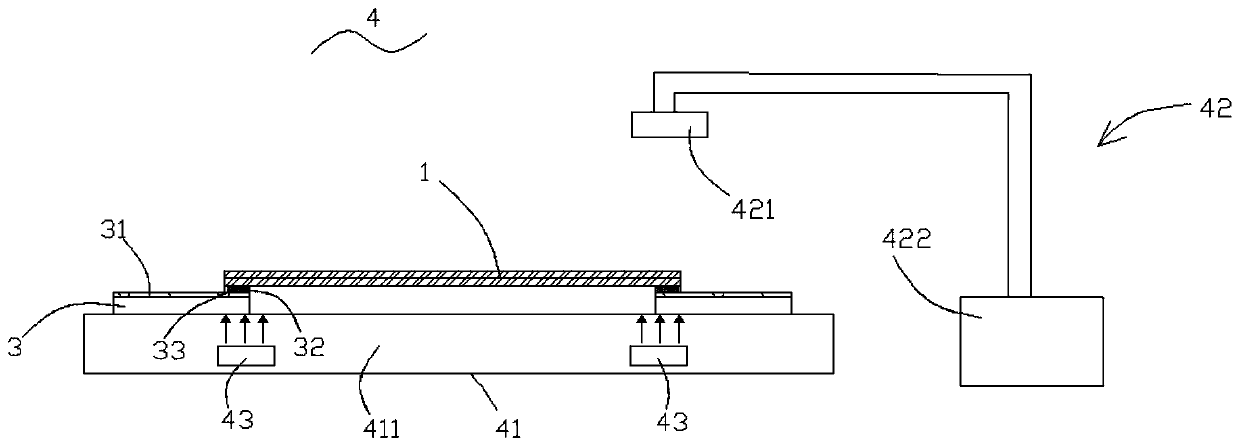

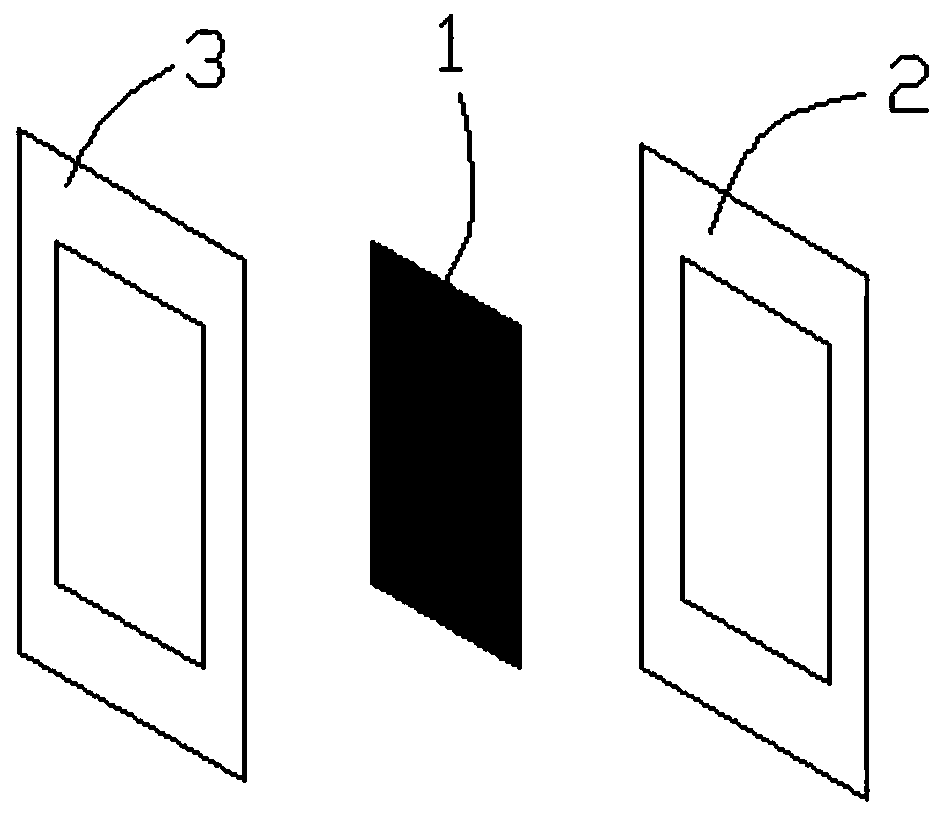

[0027] Such as Figure 1-3 As shown, a fuel cell membrane electrode frame bonding device of the present invention, the bonded membrane electrode includes a CCM1 and an upper frame 2 and a lower frame 3 bonded on both sides thereof, including a frame for bonding the CCM1 and the lower frame The lower frame fitting mechanism 4 of 3 and the upper frame fitting mechanism 5 that fits the upper frame 2 on the CCM1 and the lower frame 3 that have been bonded together;

[0028] The lower frame bonding mechanism 4 includes a lower base 41, a sprayed part 42 and an ultraviolet lamp 43. The upper surface of the lower frame 3 is coated with a hot melt adhesive layer 31, and the lower surface of the lower frame 3 is placed on the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com