High-frequency broadband underwater acoustic transducer and manufacturing method thereof

An underwater acoustic transducer and broadband technology, applied in the direction of piezoelectric/electrostrictive transducers, sensors, sensor types, etc., can solve problems such as unstable structure, easy deformation, and complicated electrode preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, and Not all examples.

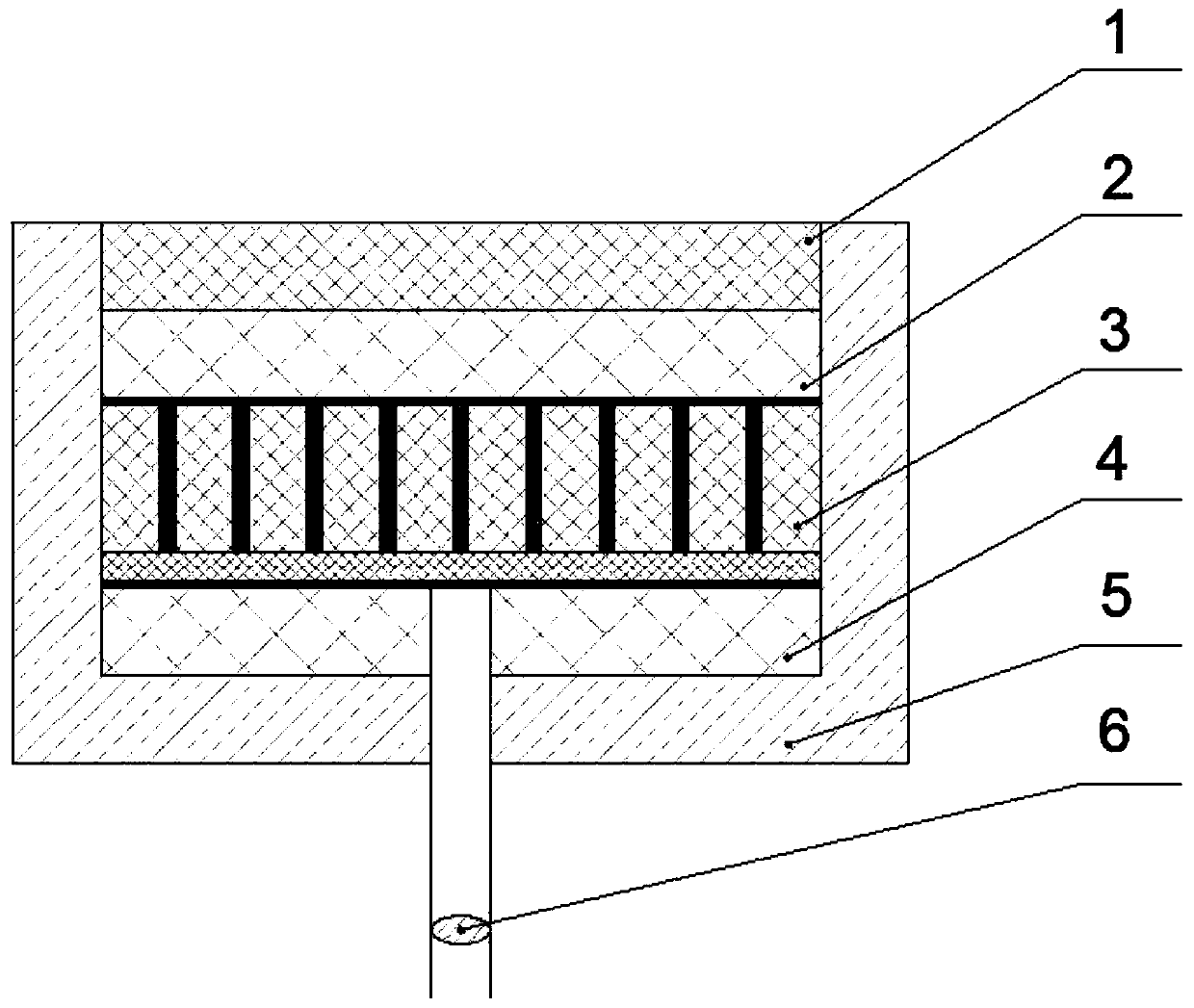

[0028] Such as figure 1 As shown, a high-frequency broadband underwater acoustic transducer of the present invention includes a matching layer 2, a wafer 3 and a backing layer 4 installed in parallel in the housing 5 from top to bottom; With sound-transmitting cladding 1;

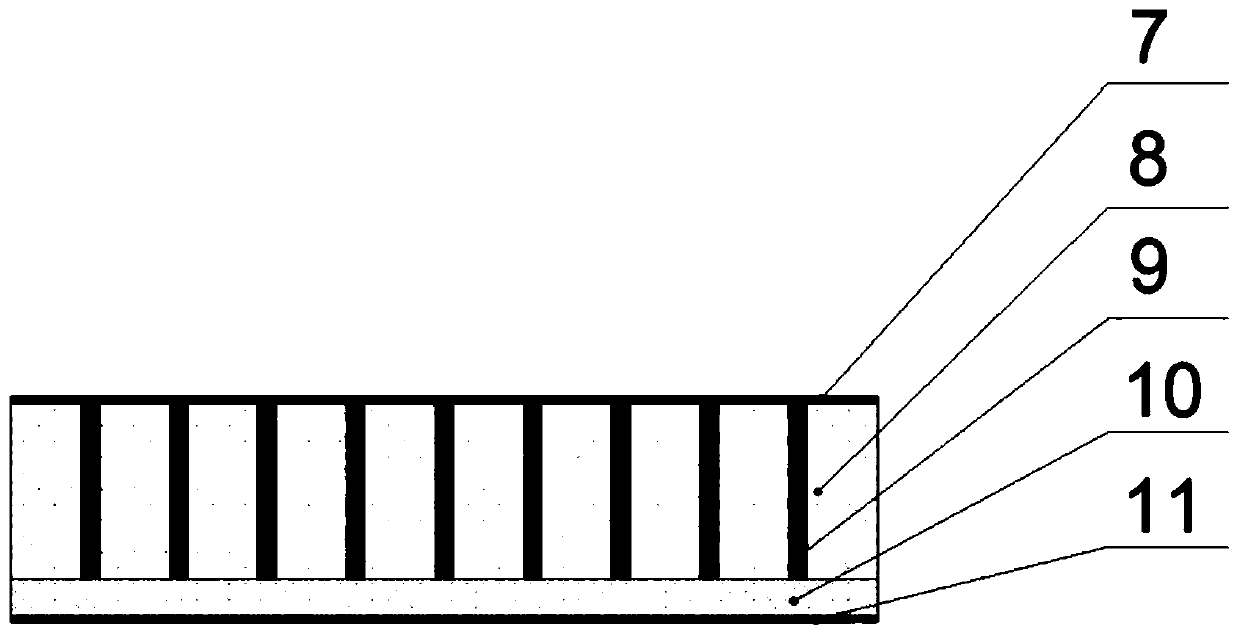

[0029] Such as figure 2 As shown, the wafer 3 is a 1-3-2 type piezoelectric ceramic composite material structure, which includes a ceramic substrate 10, and a plurality of ceramic primitives 8 are grown on the top of the ceramic substrate 10, and every two ceramic primitives 8 They are connected by a polymer 9; an upper electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com