Polymer modified asphalt, and preparation method thereof

A technology of modified asphalt and polymer, which is applied in the direction of building structure, building components, building insulation materials, etc. It can solve the problems of the influence of modified asphalt on the performance of modified asphalt and weaken the adhesion between modified asphalt and aggregate, so as to slow down Effects of long-term aging, shortening storage stability time, and improving cross-linking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

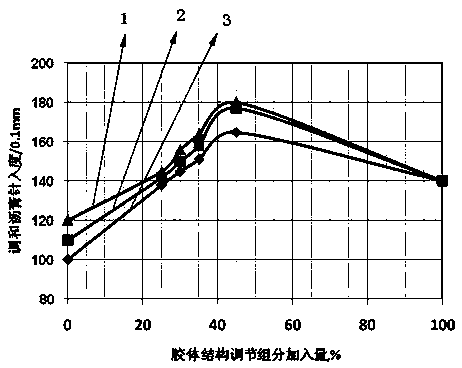

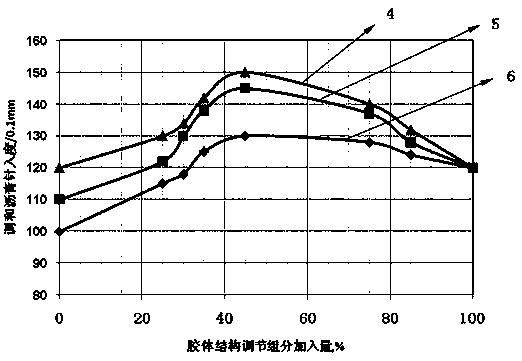

[0052] Example 1 Preparation of blended asphalt

[0053] See Table 1-1 and Table 1-2 for the properties of base bitumen, colloidal structure regulating components and Jingmen extracted oil respectively. Heat and melt the base asphalt and the colloidal structure adjustment components respectively, mix them according to the ratio shown in Table 2, and stir for 1 hour at 155°C to obtain the blended asphalt. See the raw materials and properties of the blended asphalt figure 1 , figure 2 , Table 1-1, 1-2 and Table 2. The matrix bitumen is derived from naphthenic crude oil, and the colloid structure adjustment component is derived from intermediate base crude oil.

[0054] project Base bitumen (P100) Base Bitumen (P110) Base bitumen (P120) Colloidal Structure Modulating Component (P120) Colloidal Structure Modulating Component (P140) Penetration (25℃) / 0.1mm 100 110 120 120 140 PI value -1.24 -1.28 -1.45 0.9 0.8 Softening point / ℃ 44.0 ...

Embodiment 2

[0058] Example 2 Preparation of polymer modified asphalt

[0059] Heat the blended asphalt to 160°C, add SBS and then shear or grind for 0.5 hours, add 1 / 2 of the stabilizer and 1 / 2 of the accelerator, continue to shear or grind for 0.5 hours, then raise the temperature to 185°C, and then add For the remaining stabilizer and accelerator, continue to stir for 3 hours to obtain polymer-modified asphalt.

[0060] polymer modified bitumen Blended asphalt and its content SBS and content Stabilizer and content Accelerator and content Example 2-1 Blended asphalt-1, 92.4% YH-791, 6% Sublimed sulfur, 0.8% Lanthanum diethyldithiocarbamate, 0.8% Example 2-2 Blended bitumen-4, 92.4% YH-791, 6% Sublimed sulfur, 0.8% Lanthanum diethyldithiocarbamate, 0.8% Comparative example 1 Blended bitumen-5, 92.4% YH-791, 6% Sublimed sulfur, 0.8% Lanthanum diethyldithiocarbamate, 0.8% Comparative example 2 Blended bitumen-5, 92.4% YH-791, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com