Tunnel-type drying kiln for dried bamboo shoot

A technology of tunnel drying and kiln drying, which is applied in food preservation, presses, fruit and vegetable preservation, etc. It can solve the problems of high tissue density of dried bamboo shoots, low equipment utilization rate, and large temperature gradient in working conditions, so as to shorten the drying time. The effect of time, dense structure and small temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

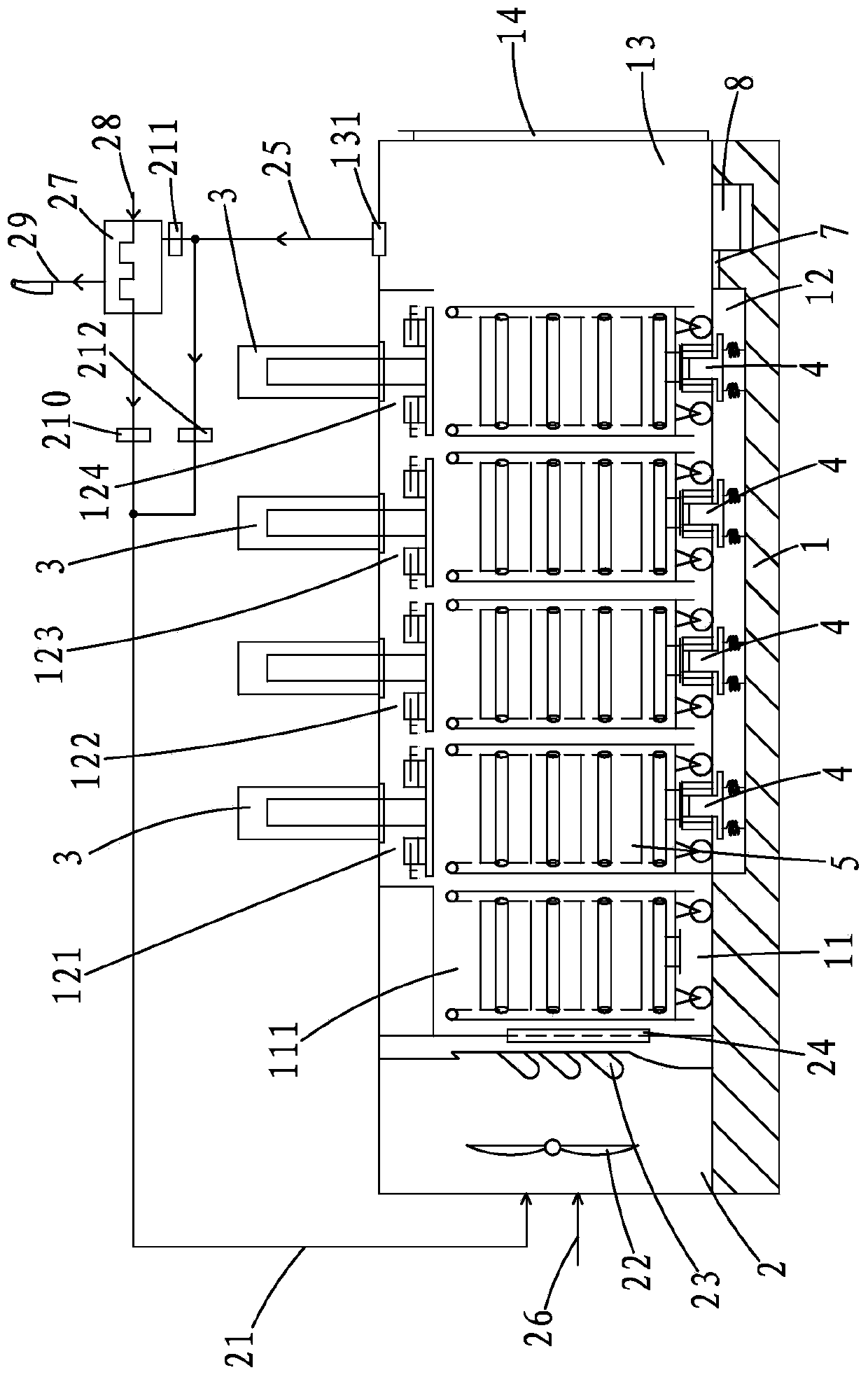

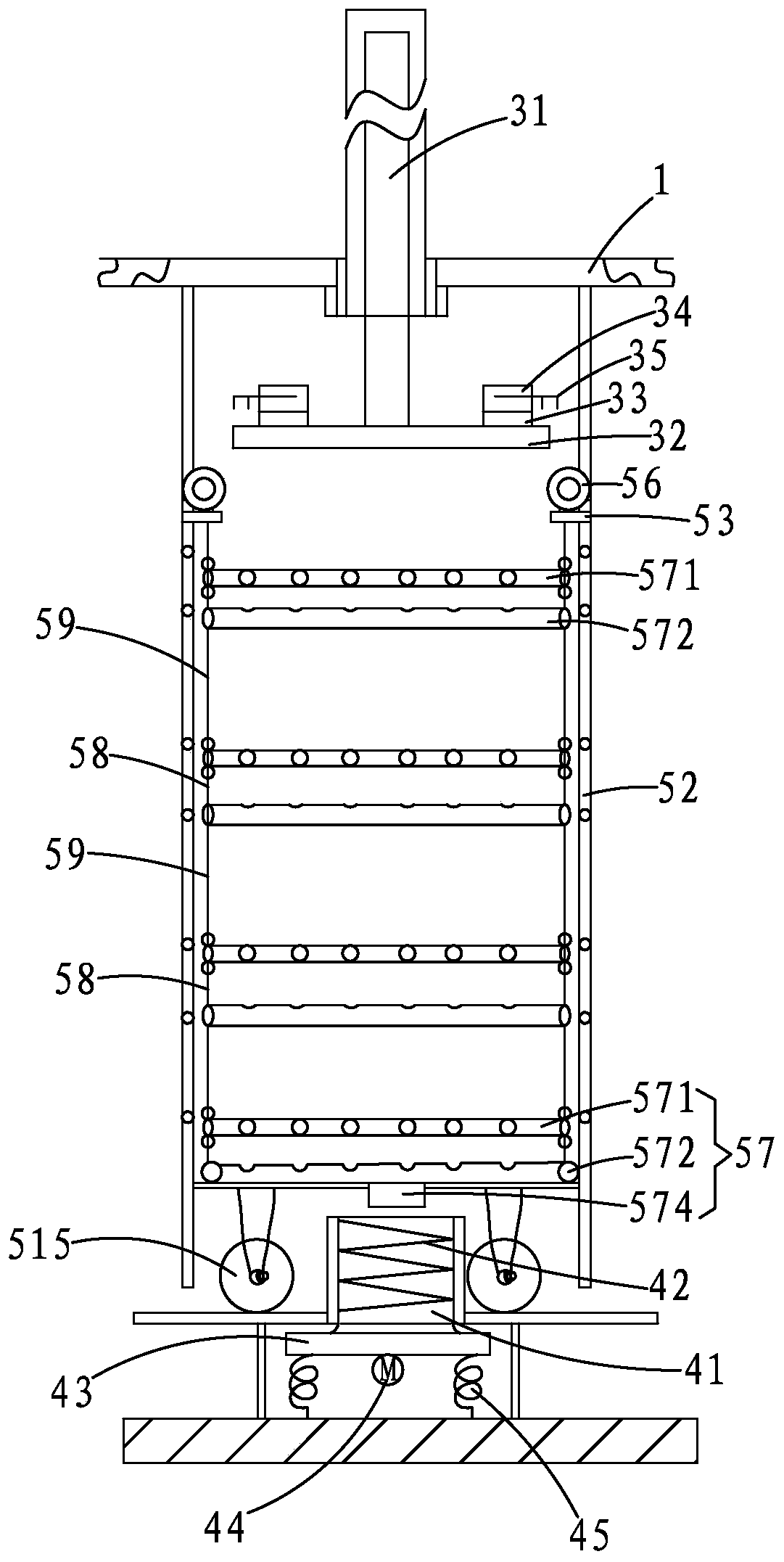

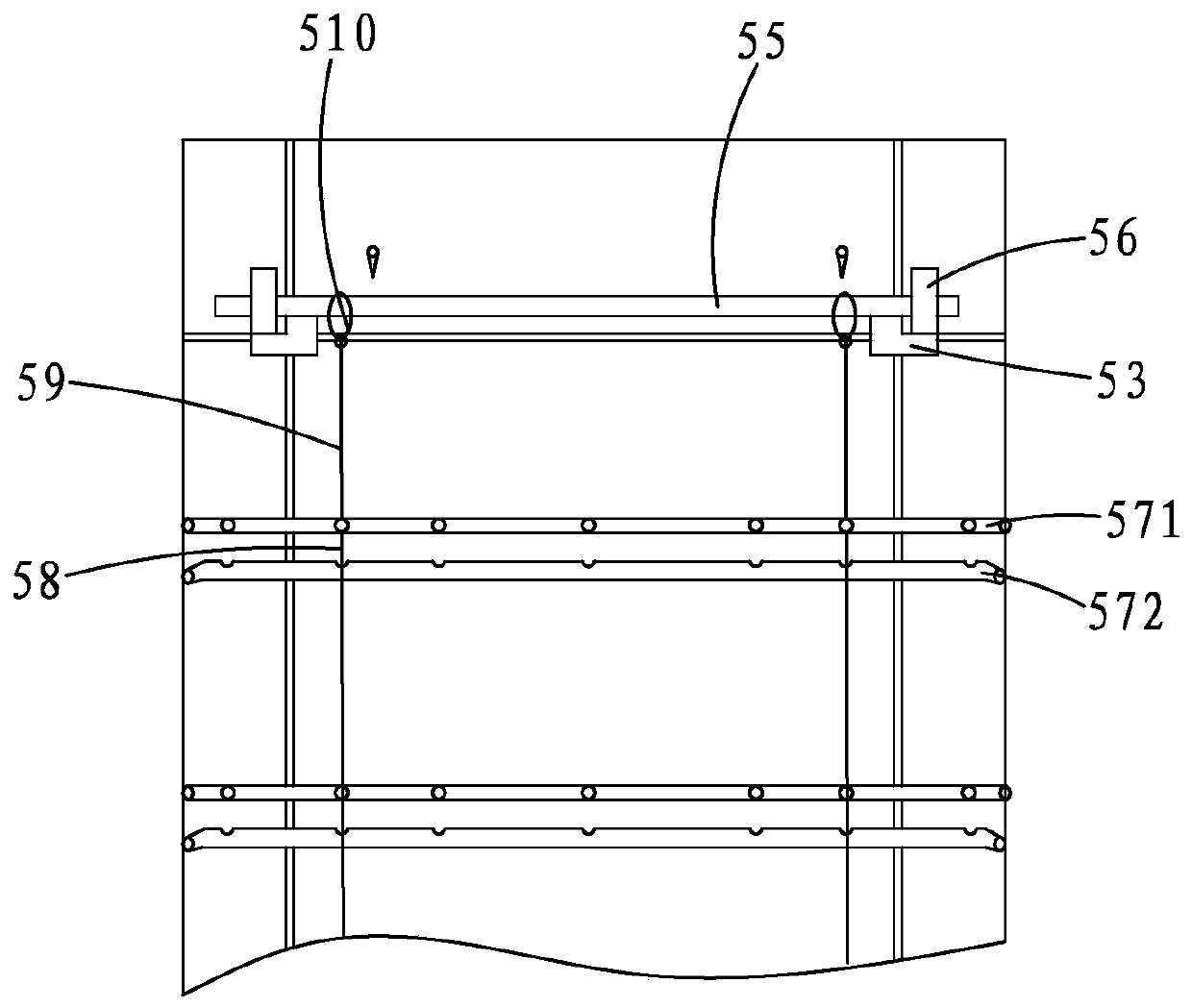

[0050] refer to Figure 1 to Figure 13 , a preferred embodiment of the tunnel-type dried bamboo shoots drying kiln of the present invention; comprising a tunnel drying kiln box 1, which is provided with a common dried bamboo shoots baking area 11, a dried bamboo shoots pressing unit area 12 and a hot air discharge area 13; hot air heating The device 2 is arranged at the left end of the conventional dried bamboo shoots area 11; the hot air blown out is used to roast the bamboo shoots, and flows from the dried bamboo shoots conventional roasted area 11 to the dried bamboo shoots pressing unit area 12, and then to the hot air discharge area 13. The tunnel drying kiln box 1 is discharged from the discharge port 131 of the hot gas discharge area 13, so that the temperature gradient of the equipment is small, the thermal power can be much smaller than that of the traditional oven, and the thermal energy utilization rate is high. The dried bamboo shoots pressing device 3 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com