Accumulated water treatment device of steaming and baking oven, steaming and baking oven and control method

A processing device and control method technology, applied to heating devices, roasters/barbecue grids, steam cooking utensils, etc., can solve problems such as deformation of stainless steel inner tanks, pollution of the working environment of heating chambers, and health hazards, and achieve improved The utilization rate of heat, avoiding the risk of scalding, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

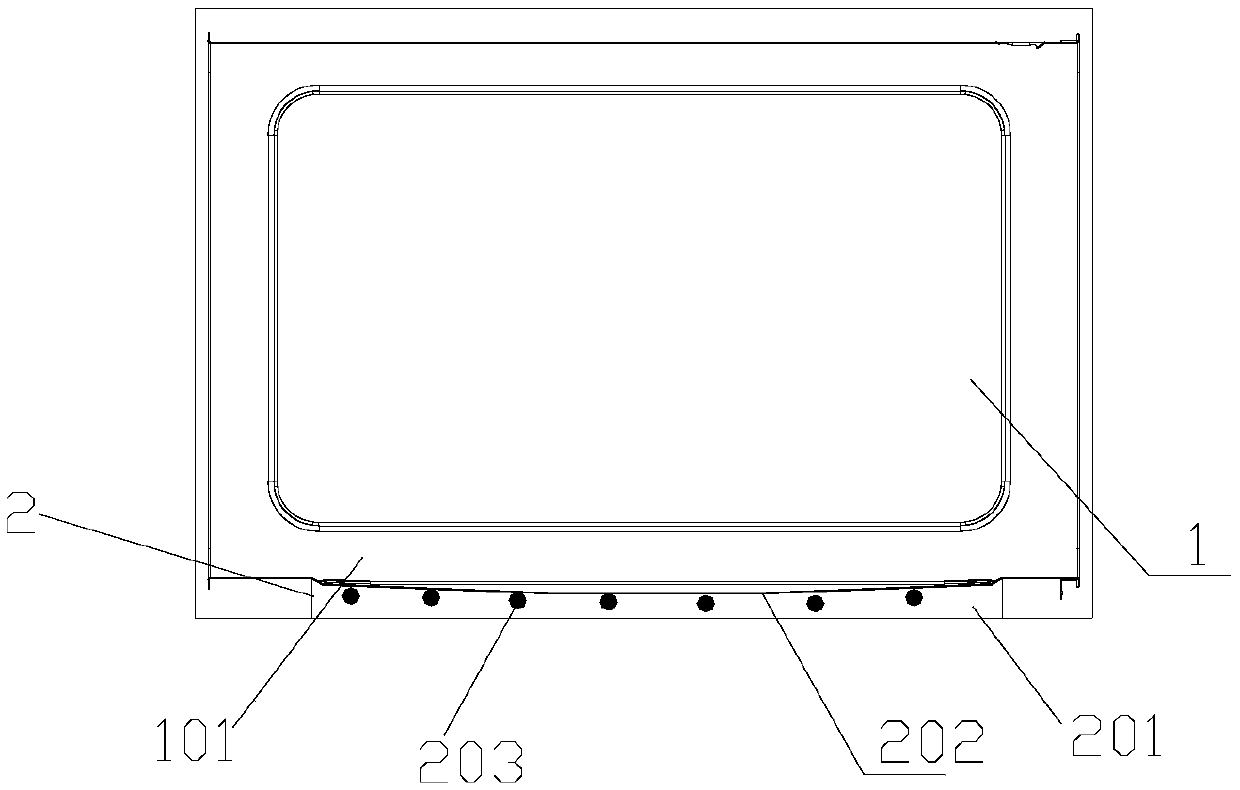

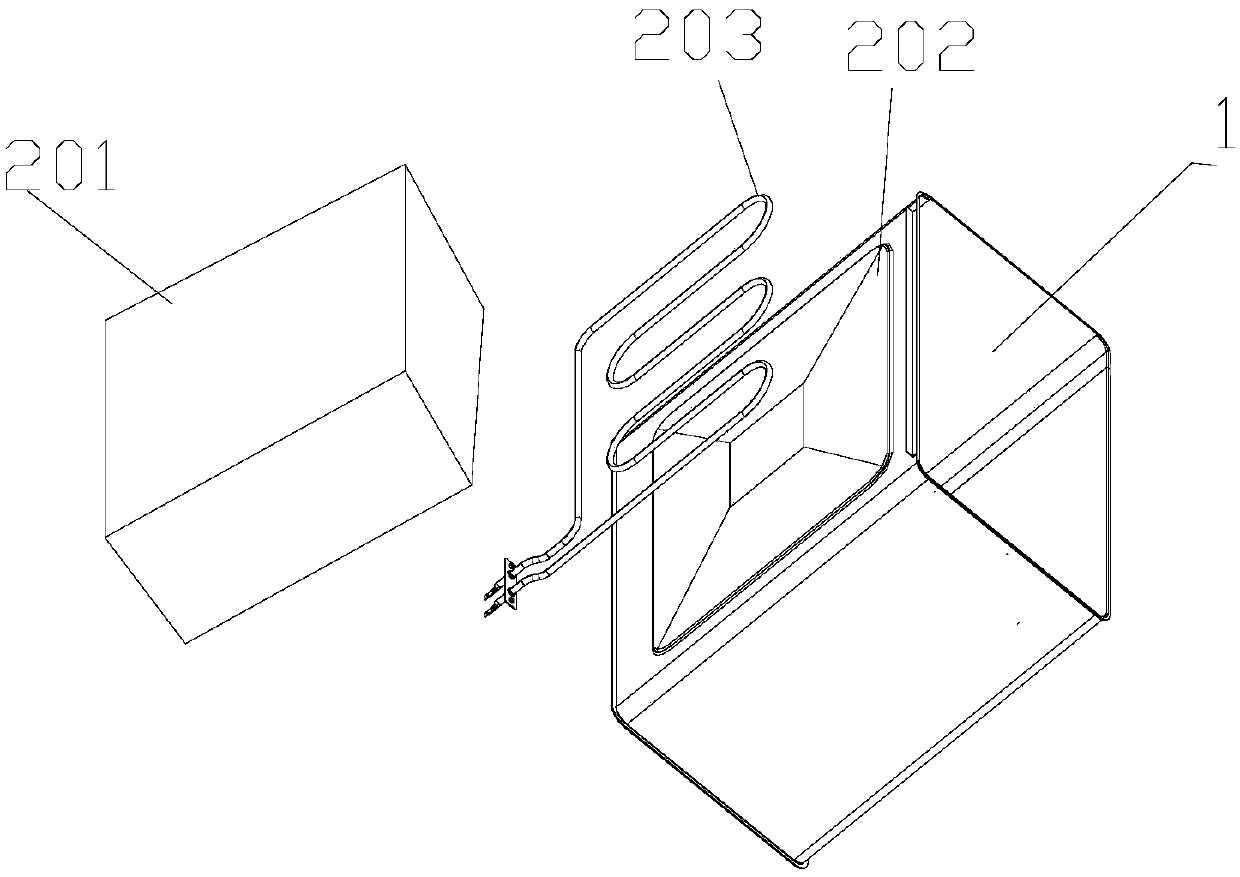

[0048] Such as figure 1 and figure 2 , Figure 5 As shown, this embodiment discloses a storage water treatment device for a steam oven. Such as figure 1 As shown, the steam oven in this embodiment has a chamber 1 for accommodating objects to be heated, and the accumulated water treatment device 2 of the present invention for eliminating accumulated water in the steam oven is provided outside the chamber 1 . The accumulated water treatment device 2 includes a heating device, which heats the bottom of the chamber 1 to treat the accumulated water. Since the stagnant water generated when the steamer is heated will eventually collect at the bottom of the chamber, the heating device is used to heat the bottom of the steamer so that the evaporated water will be discharged through the vent holes or openings of the steamer. Thereby eliminating accumulated water in the chamber.

[0049] Such as figure 1 and figure 2 As shown, the heating device includes a heating device 203 for...

Embodiment 2

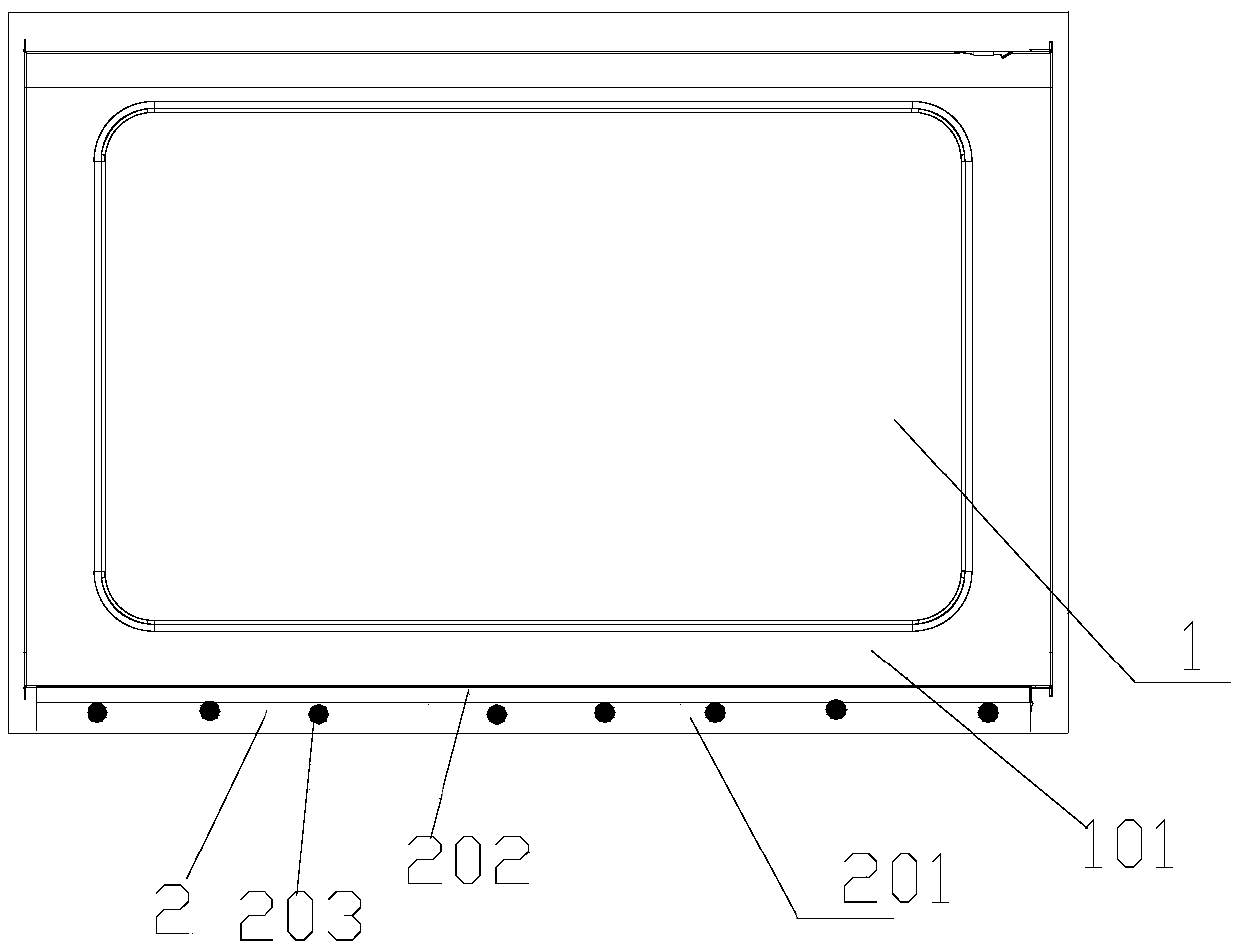

[0058] Such as image 3 As shown, this embodiment is a supplement to Embodiment 1, and discloses a storage water treatment device for a steam oven. Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the entire surface of the heat conduction plate 202 is completely attached to the surface of the chamber 1, and there is no cavity between the heat conduction plate 202 and the surface of the chamber 1, that is, the heat conduction plate 202 The boards are all covered on the outer surface of the bottom wall 101 of the chamber. In this embodiment, when the heating device 203 transfers heat to the interior of the chamber 1, it passes through the heat conducting plate 202, glue (which does not exist when it is mechanically connected), and the bottom wall 101 of the chamber to the interior of the chamber in sequence. , the method of heating the bottom wall 101 of the chamber outside the chamber is still used to finally achieve the purpose of he...

Embodiment 3

[0060] Such as Figure 4 As shown, this embodiment is a supplement to Embodiments 1 and 2, and discloses a water storage device for a steam oven. The difference between this embodiment and the above-mentioned embodiment is: as Figure 4 As shown, the bottom wall 101 of the chamber is partially inclined to form a deflector 102, thereby forming a water collection part at the bottom of the deflector. The heat conduction plate 202 in this embodiment only covers the bottom of the water collection part. on the outside of the wall. Under the action of the deflector 102 , the accumulated water in the chamber 1 of the steam oven in this embodiment is no longer randomly located on the entire inner surface of the bottom wall 101 of the chamber, but is collected in the water collecting part. The accumulated water treatment device 2 only heats the outer wall of the water collecting part, so that the heat generated by the heating device 203 can be more effectively used, and the resources ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com