Kitchen waste environmental protection treatment equipment

A technology for environmental protection and food waste treatment, which is applied in the direction of grain treatment, solid waste removal, mobile filter element filter, etc., can solve the problems of slow food waste treatment and inability to separate food waste from solid and liquid, and achieve convenient Effects of collecting processing, speeding up processing, and increasing travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

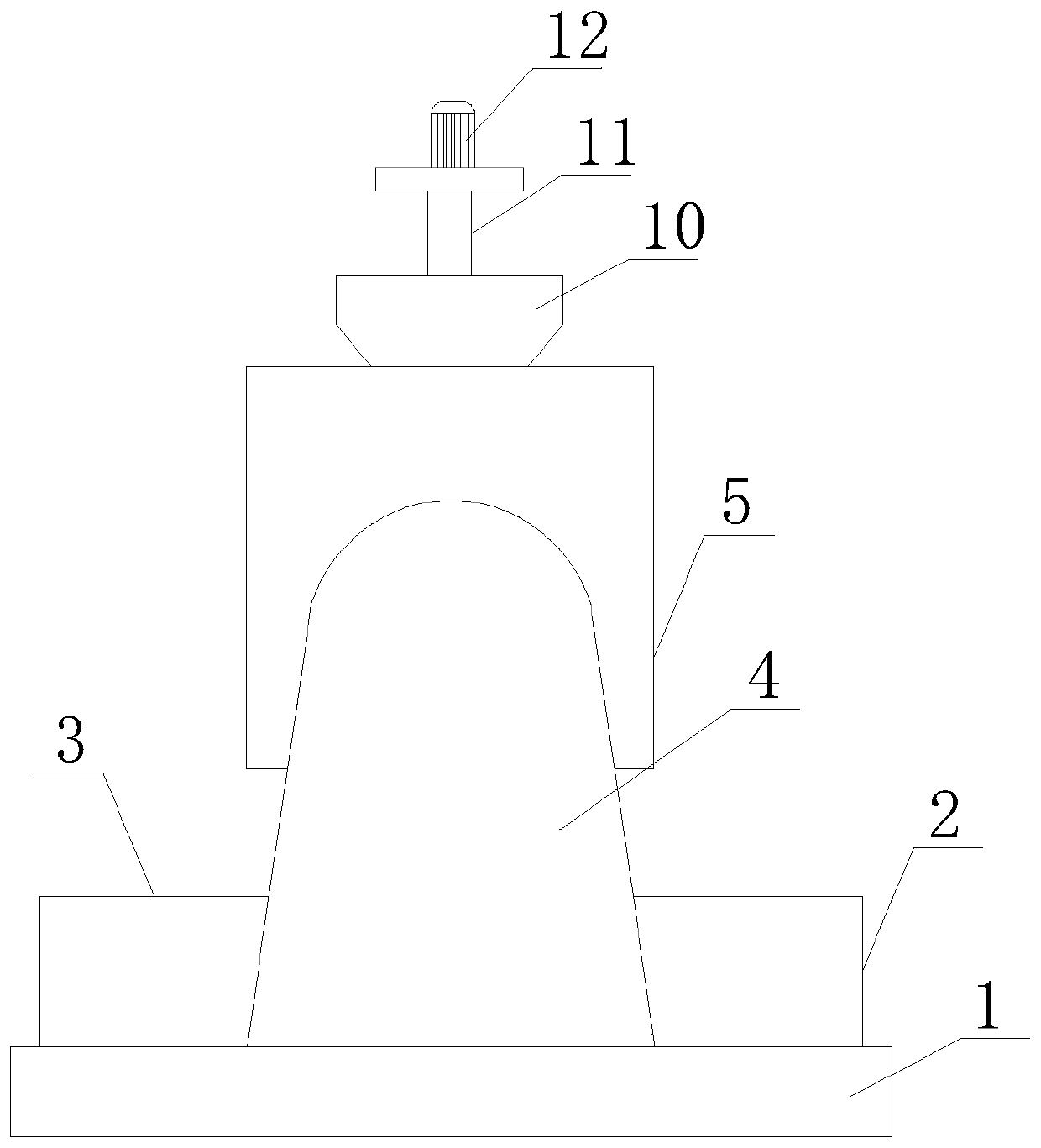

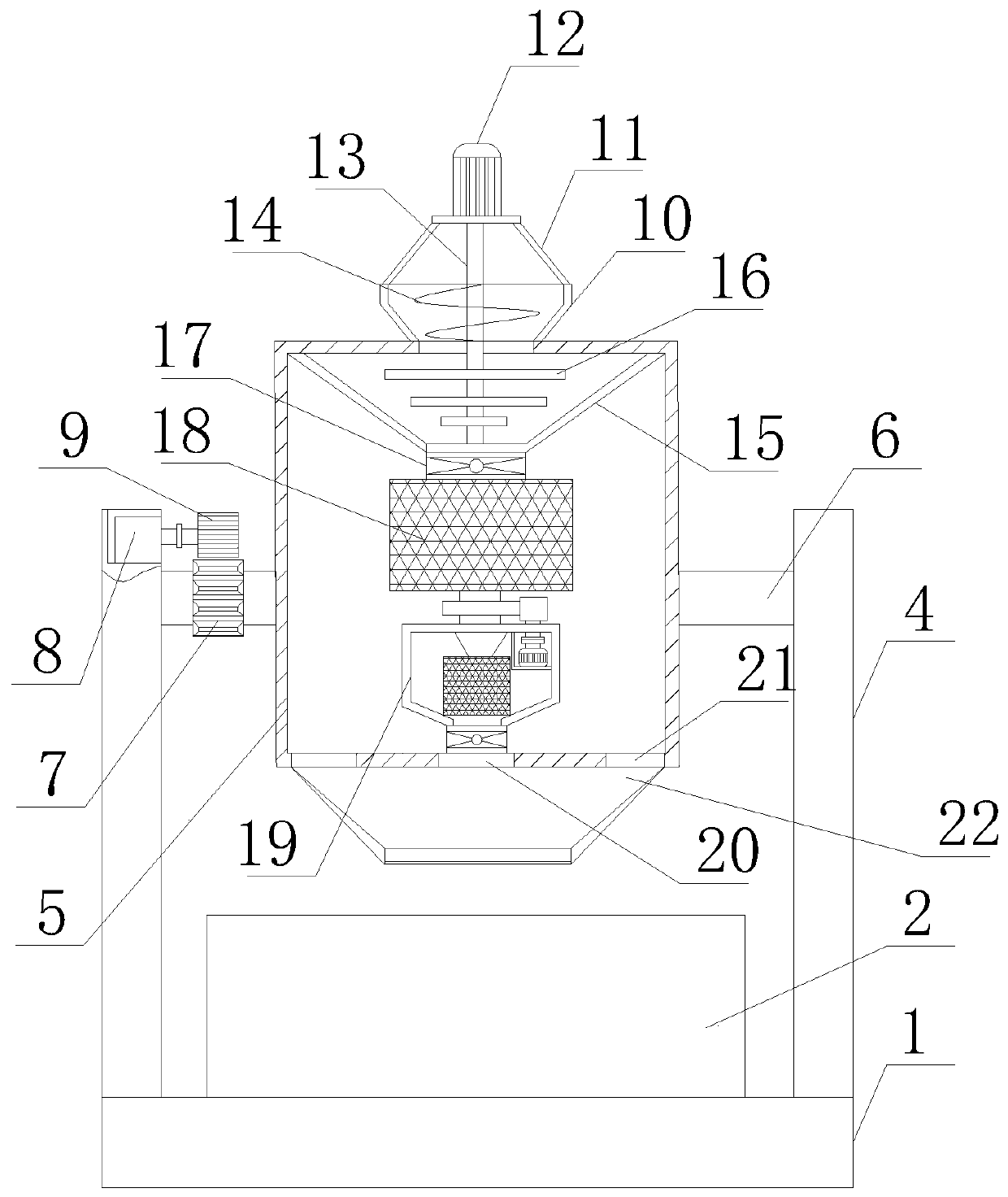

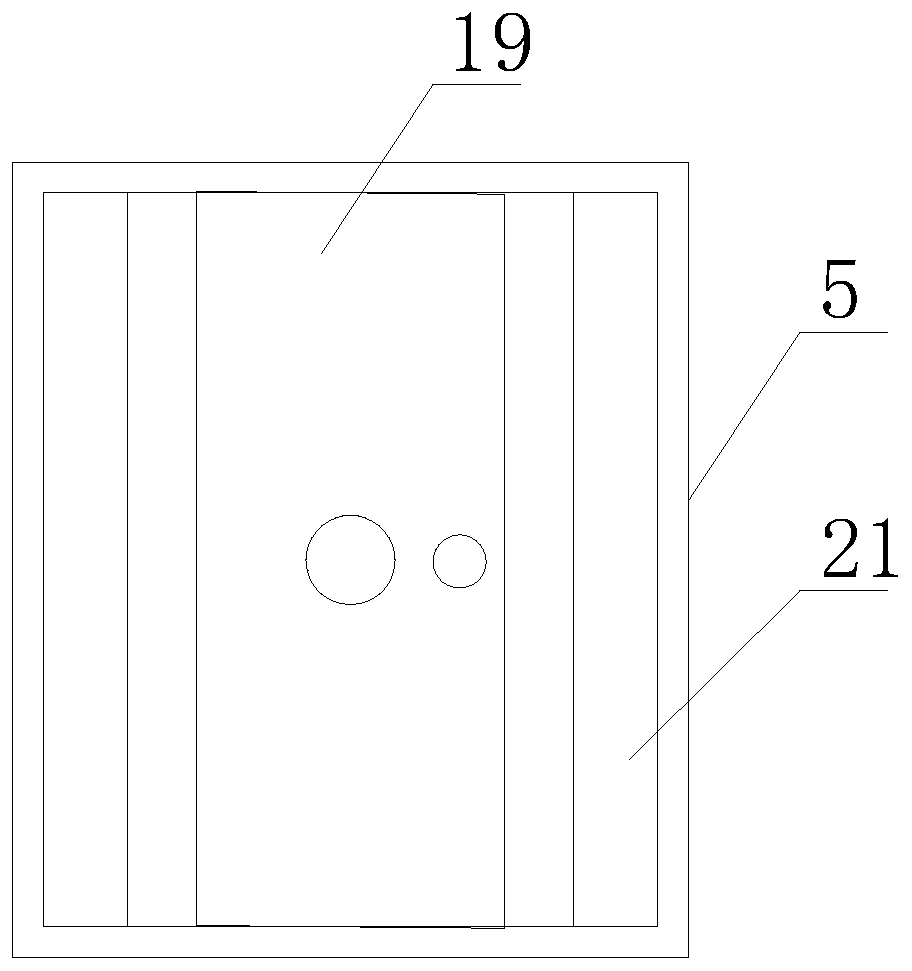

[0032] Attached below Figure 1-7 The present invention is further described with embodiment:

[0033] An environmental protection treatment equipment for kitchen waste, comprising a base 1, characterized in that: waste liquid collection boxes 3 and solid waste collection boxes 4 are respectively installed on both sides of the top of the base 1, which can be used to load waste liquid and solid waste respectively Waste, both sides of the top of the base 1 are welded with vertical plates 2, and a shell 5 is arranged between the two vertical plates 2, and the shell 5 is used for the treatment of kitchen waste. The two sides of the shell 5 Rotating rods 6 are welded at the top ends, and the end of the rotating rods 6 away from the housing 5 is rotatably connected to the side wall of the riser 2 on the corresponding side, and the side wall of one of the rotating rods 6 is sleeved with a first driven Gear 7, wherein a first motor 8 is installed on the top of one of the risers 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com