Efficient numerical control machining workbench

A technology of workbench and CNC turntable, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low clamping precision, low clamping setting operation efficiency, affecting product processing accuracy, etc., to achieve disassembly and assembly Fast, improve work efficiency and quality, repeat the effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

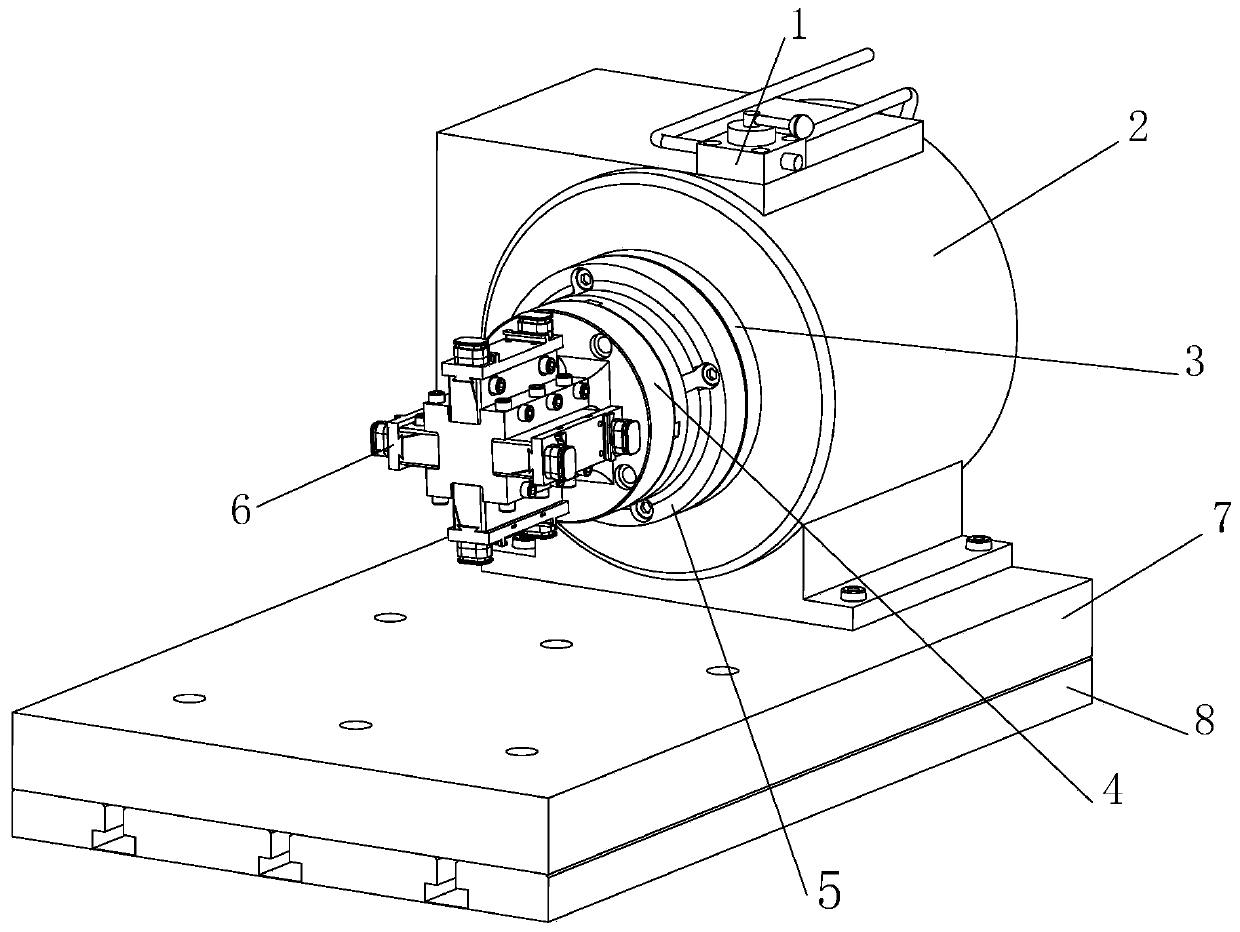

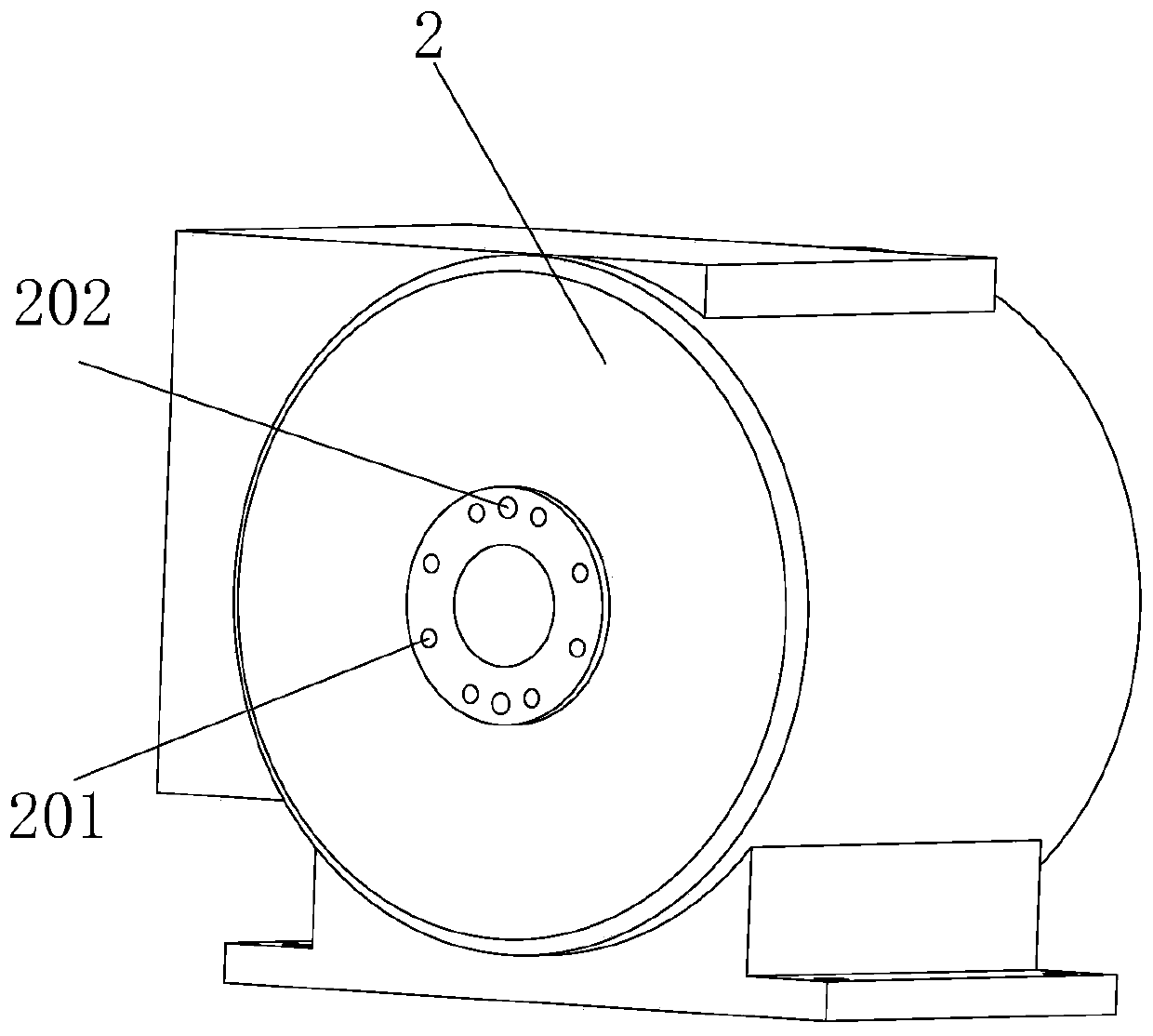

[0034]Embodiment 1: A high-efficiency numerical control machining workbench, including a pneumatic control unit 1, a four-axis numerical control turntable 2, an adapter plate 3, a positioning and clamping device 4, and a fixture 5. The pneumatic control unit 1 is provided with an air outlet pipe 101, The air outlet end of the air outlet pipe 101 is connected to the positioning and clamping device 4, and the positioning and clamping device 4 is connected to one side of the four-axis numerical control turntable 2 through the adapter plate 3, and the positioning and clamping device 4 is connected to the adapter plate 3 opposite sides are connected with a clamp 5;

[0035] The clamp 5 includes a body 501 and a clamping mechanism 502. The side of the body 501 opposite to the positioning and clamping device 4 is provided with four grooves, and a clamping mechanism 502 is clamped in each groove. A dovetail groove is provided on the top of the clamping mechanism 502, and a workpiece 6...

Embodiment 2

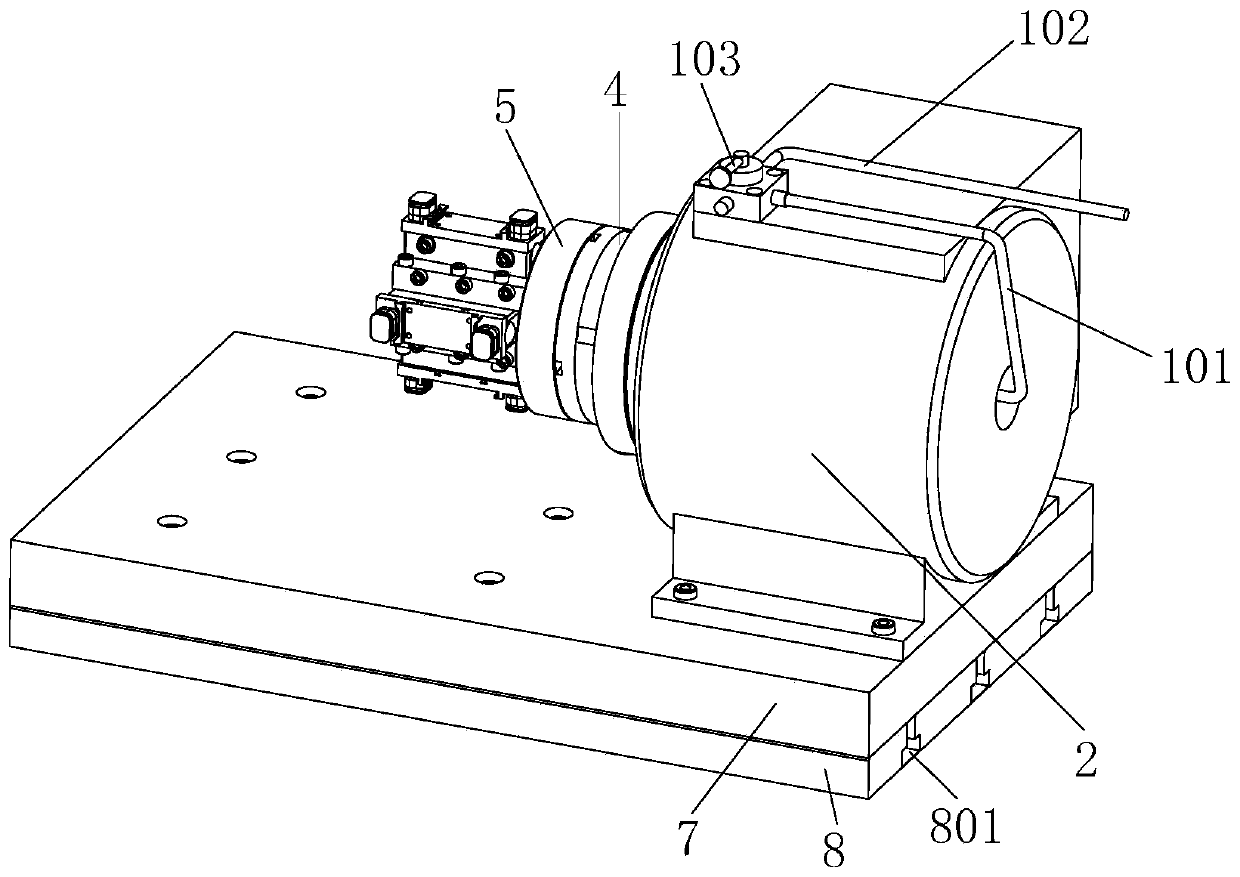

[0041] Embodiment 2: A high-efficiency CNC machining workbench, including a pneumatic control unit 1, a four-axis CNC turntable 2, an adapter plate 3, a positioning and clamping device 4, and a clamp 5, the pneumatic control unit 1 is provided with an air outlet pipe 101, The air outlet end of the air outlet pipe 101 is connected to the positioning and clamping device 4, and the positioning and clamping device 4 is connected to one side of the four-axis numerical control turntable 2 through the adapter plate 3, and the positioning and clamping device 4 is connected to the adapter plate 3 opposite sides are connected with a clamp 5;

[0042] The clamp 5 includes a body 501 and a clamping mechanism 502. The side of the body 501 opposite to the positioning and clamping device 4 is provided with four grooves, and a clamping mechanism 502 is clamped in each groove. A dovetail groove is provided on the top of the clamping mechanism 502, and a workpiece 6 is connected in the dovetail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com