Clamping device and drilling and milling machining method for resin-based composite material laminated board

A composite material layer and clamping device technology, applied in metal processing and other directions, can solve problems such as reduction, and achieve the effects of reducing processing temperature, cutting tool loss, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with the following examples.

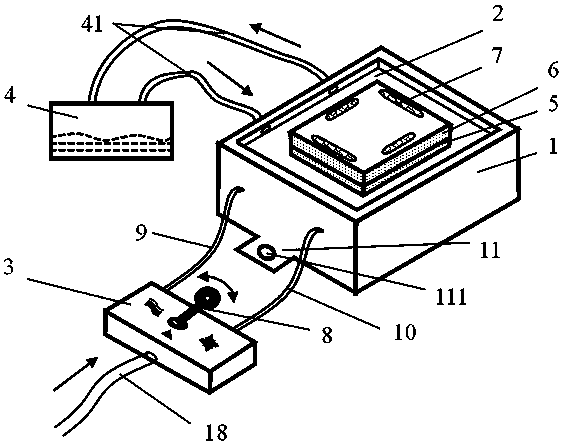

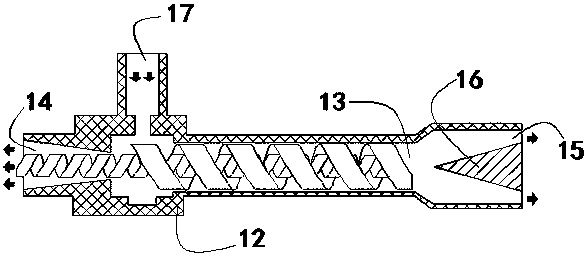

[0035] Such as Figure 1-2As shown, a clamping device for resin-based composite laminates in this embodiment includes an ice tray device 1, a water circulation device 4 and a gas conversion device 3, and a vortex tube 12 is provided inside the gas conversion device 3 , the ice tray device 1 communicates with the cold air outlet 14 and the hot air outlet 15 of the vortex tube 12 inside the gas conversion device 3 respectively through the air transmission pipe, and the upper end of the gas conversion device 3 is movably connected with an operating handle 8, The operating handle 8 is bolted to the control valve 16 of the vortex tube 12, and the ice tray device 1 is provided with a groove 2 for placing workpieces to be processed. Adjust the depth of the water inside the groove 2, so that the adjustment of the clamping force of the ice tray device 1 can be realized. The water circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com