Low-cost lightweight 600mpa-grade automobile body steel and production method thereof

A production method and lightweight technology, applied in the field of hot-rolled high-strength steel production, can solve problems such as large residual stress, low strength level, and unstable plate quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

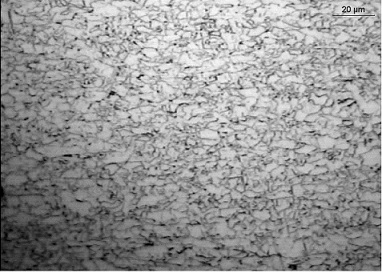

Embodiment 1

[0031] A low-cost lightweight 600MPa-grade automobile body steel, its chemical composition and mass percentage are: C: 0.056%, Si: 0.07%, Mn: 1.10%, P: 0.010%, S: 0.003%, Als: 0.030%, Ti: 0.087%, the balance is Fe and unavoidable impurities;

[0032] A production method of low-cost lightweight 600MPa-grade automobile body steel, including converter smelting, refining, continuous casting, heating, rolling, cooling, coiling, warehousing and stacking, and leveling processes; the specific process steps are as follows :

[0033] (1) Converter and refining process: use a 250-ton top-bottom combined blowing converter for smelting, blowing for 15 minutes, and the end point P is 0.009wt%; tapping for deoxidation and alloying, and the acid-soluble aluminum Als in molten steel at the end of tapping: 0.013wt% ; The whole process of refining LF is slightly positive pressure, the pressure is 45Kpa, the top slag is transformed into reducing slag within 3 minutes, the molten steel is strongl...

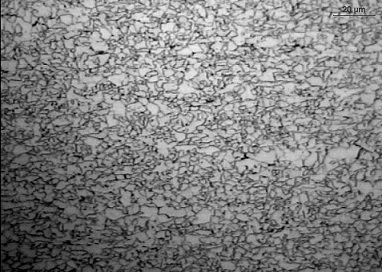

Embodiment 2

[0043] A low-cost lightweight 600MPa grade automobile body steel and its preparation method, its chemical composition and mass percentage are: C: 0.090%, Si: 0.12%, Mn: 1.30%, P: 0.016%, S : 0.005%, Als: 0.045%, Ti: 0.100%, the balance is Fe and unavoidable impurities. The concrete processing step of preparation method is as follows:

[0044] (1) Converter and refining process: use a 250-ton top-bottom combined blowing converter for smelting, blowing for 15 minutes, and the end point P is 0.012wt%; tapping is carried out for deoxidation and alloying, and the acid-soluble aluminum Als in molten steel at the end of tapping: 0.020wt% ; The whole process of refining LF is slightly positive pressure, pressure 45Kpa, within 4 minutes the top slag is transformed into reducing slag, the molten steel is strongly stirred for 5 minutes, S reaches 0.005wt%, after alloying, temperature adjustment, and calcium treatment, argon is blown at the bottom of the ladle to clean Blow for 8 minutes...

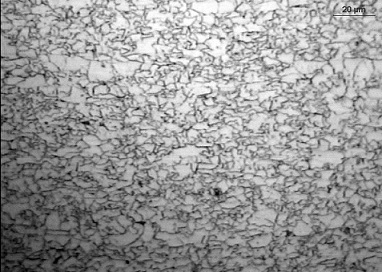

Embodiment 3

[0054] A low-cost lightweight 600MPa grade automobile body steel and its preparation method, its chemical composition and mass percentage are: C: 0.050%, Si: 0.08%, Mn: 1.00%, P: 0.011%, S : 0.004%, Als: 0.015%, Ti: 0.070%, the balance is Fe and unavoidable impurities. The concrete processing step of preparation method is as follows:

[0055] (1) Converter and refining process: use a 250-ton top-bottom combined blowing converter for smelting, blowing for 13 minutes, and the end point P is 0.010wt%; tapping for deoxidation and alloying, and the acid-soluble aluminum Als in molten steel at the end of tapping: 0.017wt% ; The whole process of refining LF is slightly positive pressure, pressure 45Kpa, within 3 minutes the top slag is transformed into reducing slag, the molten steel is strongly stirred for 5 minutes, S reaches 0.003wt%, after alloying, temperature adjustment, and calcium treatment, the bottom of the ladle is blown with argon to clean Blow for 8 minutes and leave th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com