Optimal design method for off-axis tensile test piece of one-way ceramic matrix composite

A technology for composite materials and tensile tests, applied in calculations, special data processing applications, instruments, etc., can solve problems such as low success rate, insufficient, and incomplete disclosure of matrix fiber evolution rules, etc., to achieve improved success rate and uniform stress , The effect of reducing the deformation of the test piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

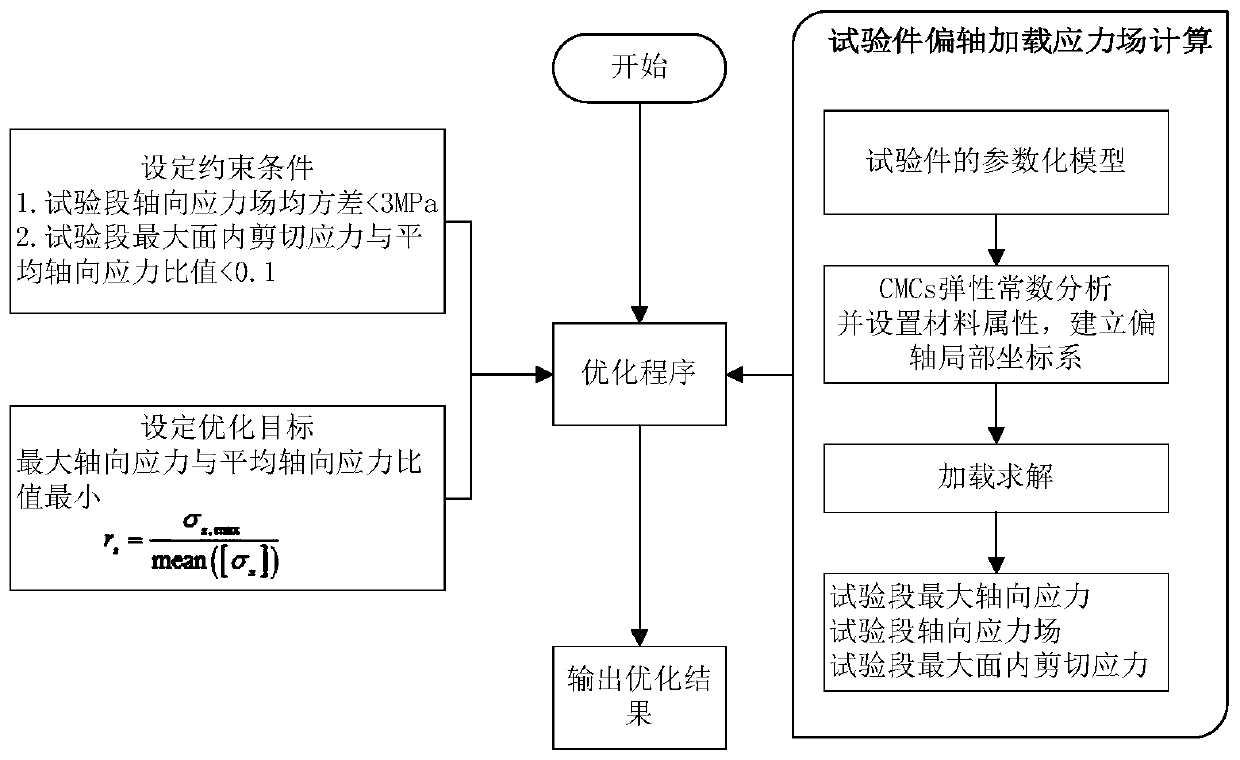

Method used

Image

Examples

Embodiment

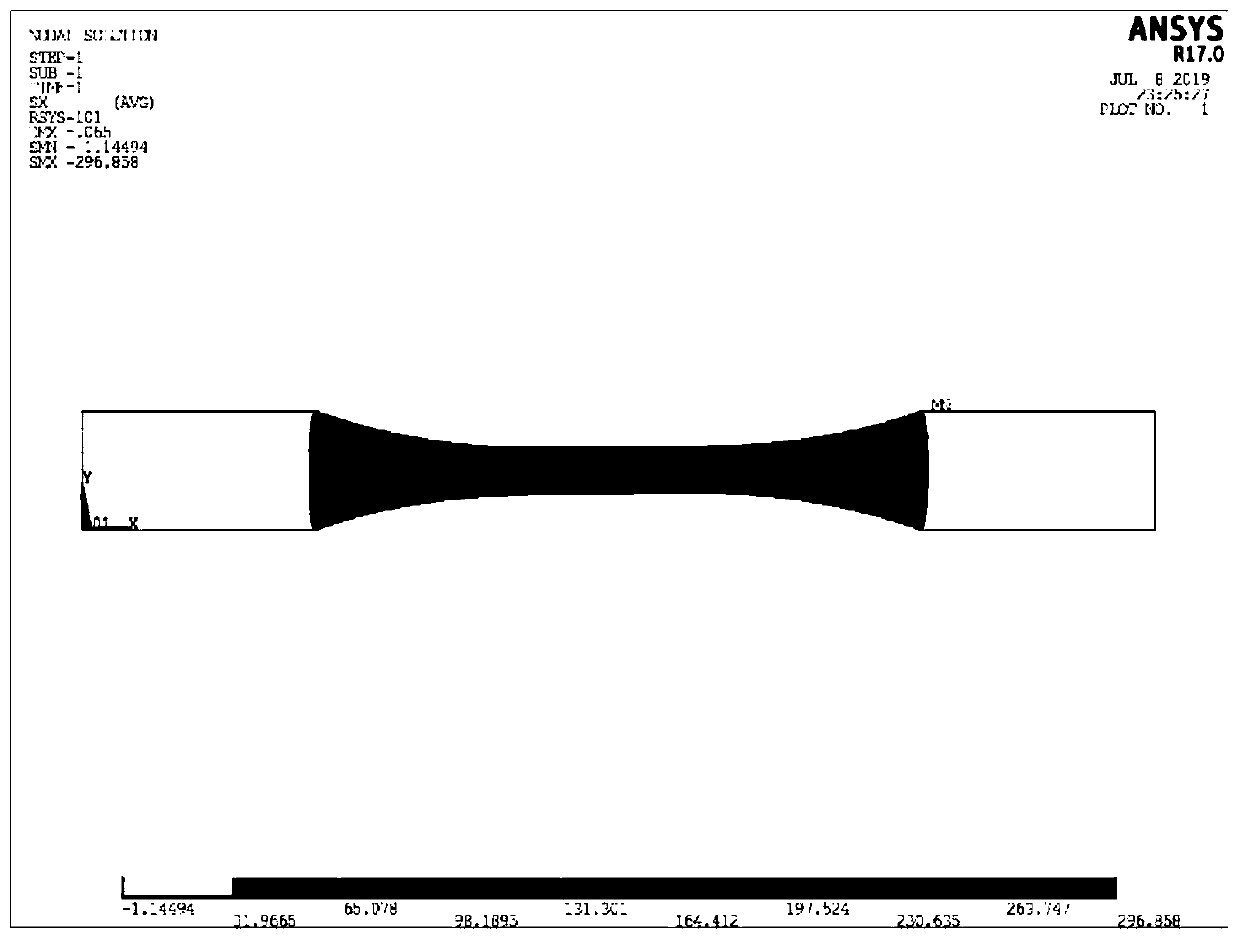

[0113]Take the off-axis angle θ=3 degrees as an example. The stress distribution of the unoptimized 3-degree off-axis test piece and the optimized stress distribution of the 3-degree off-axis test piece were modeled and calculated in ANSYS. The results are attached Figure 3-6 shown in . Different colors in the figure represent different stress magnitudes, and the lighter the color of the test section, the greater the stress value.

[0114] Compared image 3 and Figure 5 It can be seen that the fiber axial stress of the unoptimized 3-degree off-axis test piece is approximately parallelogram, indicating that the stress distribution is uneven, and the fracture may not appear in the test section, which may lead to test failure; while the optimized 3-degree off-axis test piece The axial stress of the fiber in the shaft test piece is approximately rectangular, indicating that the stress distribution is relatively uniform, which reduces the probability of test failure.

[0115...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com