Stepwise utilization method and system of decommissioned batteries

A battery ladder and battery technology, applied in secondary batteries, battery recycling, secondary battery testing, etc., can solve the problems of battery attenuation, uneconomical, and short service life of battery packs, and achieve cost savings, low work efficiency, and process flow. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

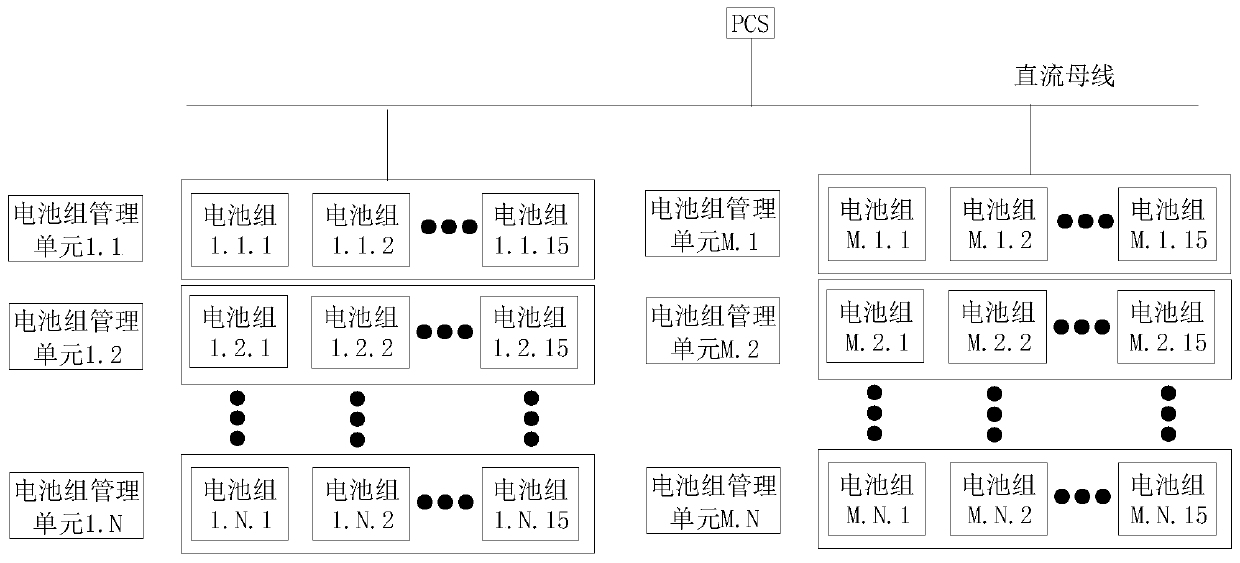

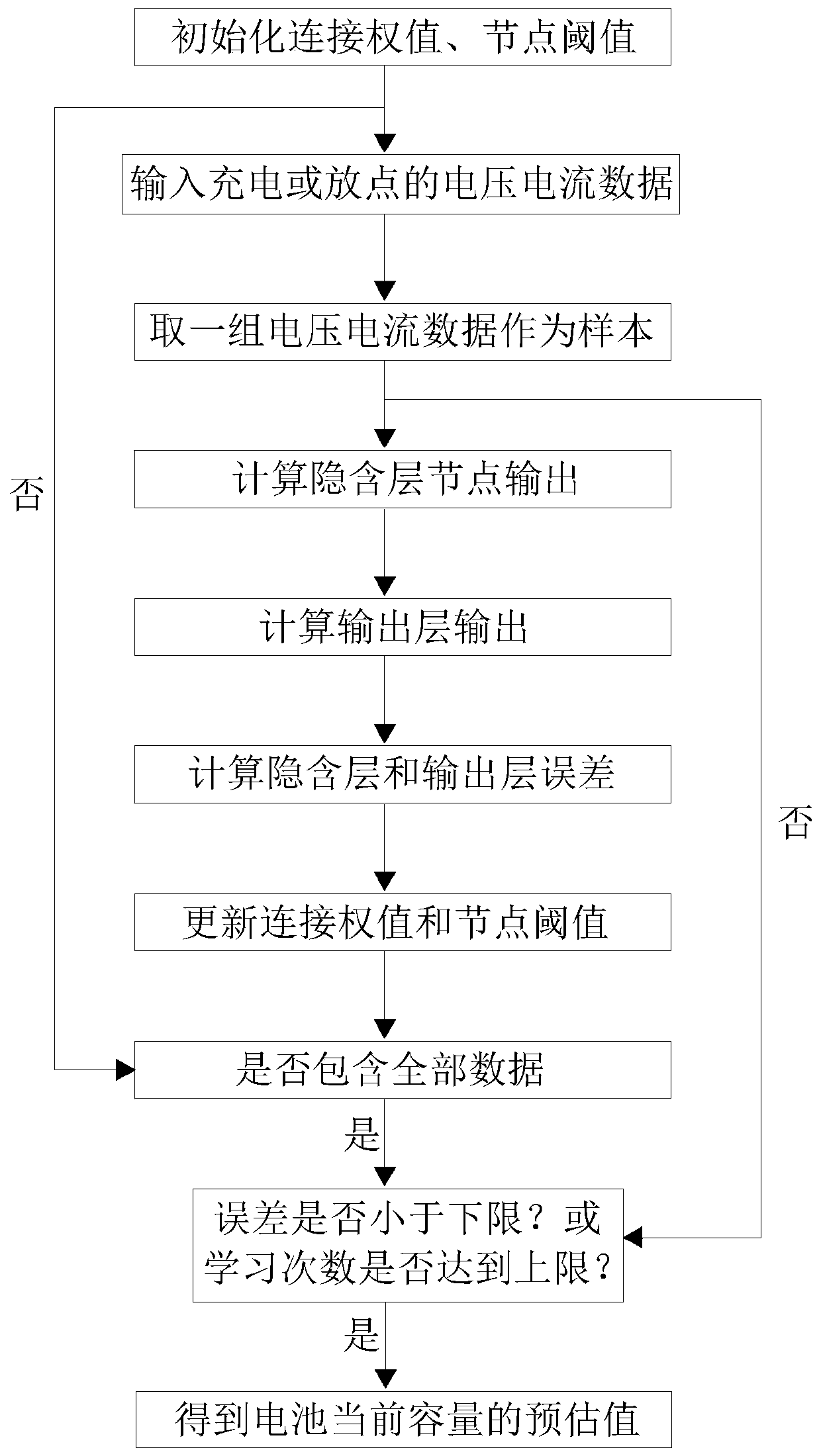

[0053] Based on the above design concept, in one of the specific limited solutions of the present invention, the cascade utilization method of decommissioned batteries includes the following steps:

[0054] A method for cascade utilization of decommissioned batteries, comprising the following steps:

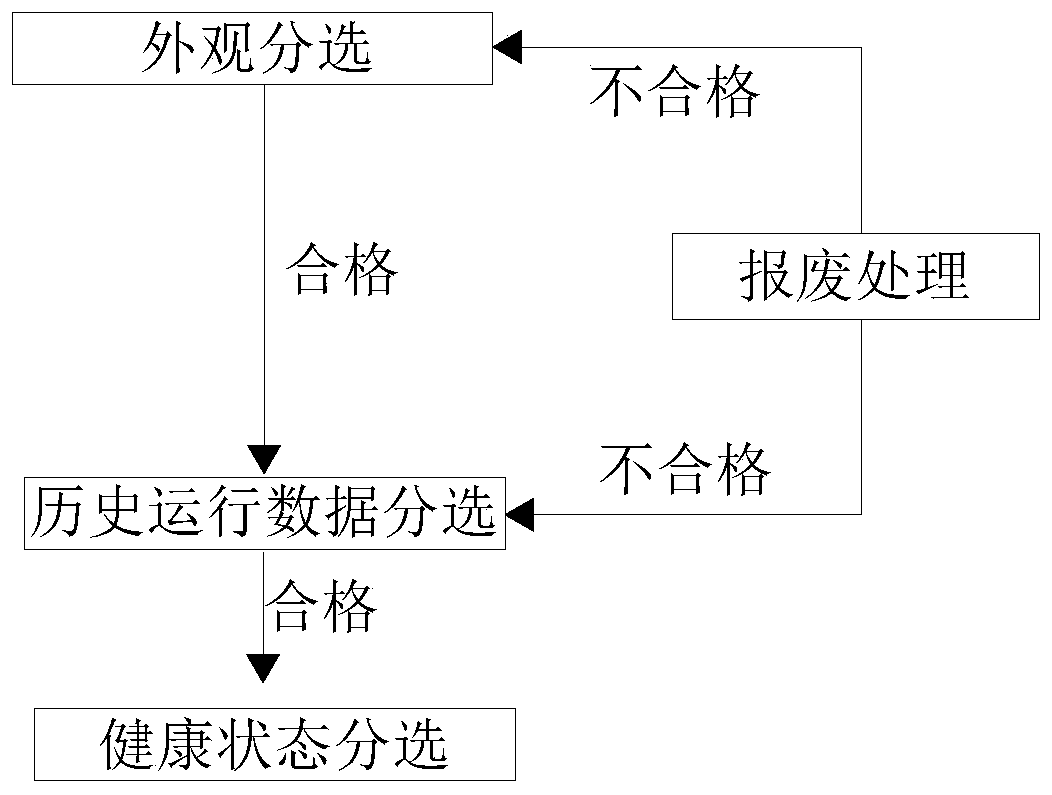

[0055] a. Sorting of decommissioned batteries: sort the decommissioned batteries according to the determined SOH standard of the battery state of health parameters, and judge whether the decommissioned batteries can be used in cascades; if yes, perform step b; if not, discard them. Preferably, the sorting step of the decommissioned batteries may include:

[0056] a1. Appearance sorting of decommissioned batteries: sort according to the determined appearance standards of decommissioned batteries, and judge whether they can enter the sorting of historical data of decommissioned batteries; more preferably, the appearance standards are: good appearance, clear and correct battery iden...

Embodiment 2

[0095] This embodiment relates to a cascade utilization of decommissioned batteries, which specifically includes the following steps:

[0096] Step 1: Appearance Sorting

[0097] First, sort the recycled lithium iron phosphate lithium-ion batteries by appearance. The specific inspection method is: under good light conditions, check whether there are any unqualified phenomena such as damage, deformation, stains, and leakage, and whether the battery identification is clear and correct. For retired batteries that fail the visual inspection, they will not be recycled; for retired batteries that pass the visual inspection, go to step 2 (such as figure 2 ).

[0098] Step 2: Sorting of historical operating data

[0099] Connect the BMS protection board of the decommissioned battery, read its historical operation data, and sort the historical operation data of the decommissioned battery; Batteries will not be recycled; for decommissioned batteries without the above conditions and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com