Chimney waste gas smoke plume removal apparatus utilizing electrostatic technology

A waste gas and chimney technology, applied in the field of high-voltage static electricity, can solve the problems of large water consumption, poor dispersion effect, low whitening efficiency, etc., and achieve the effect of simple working principle, cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

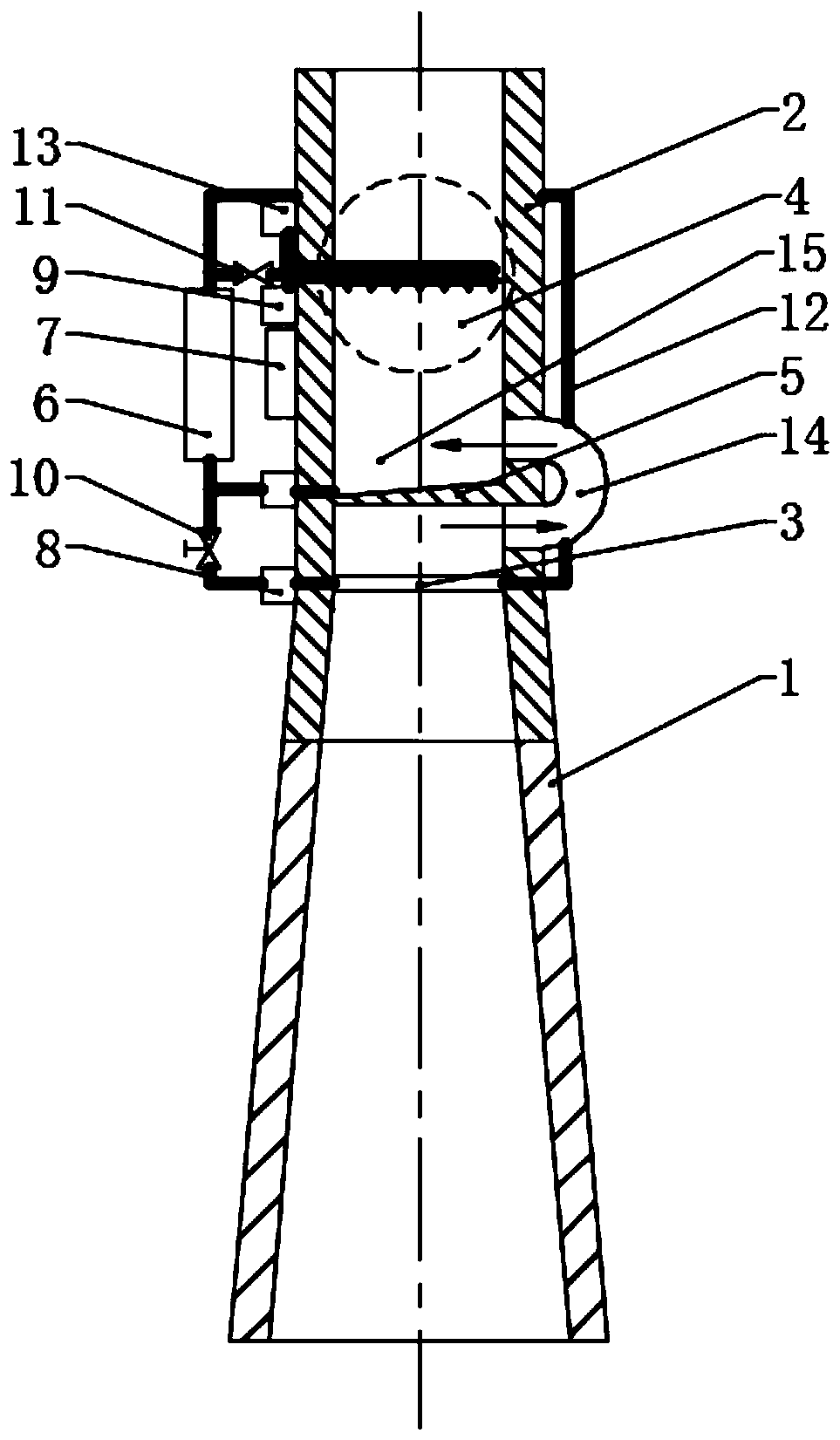

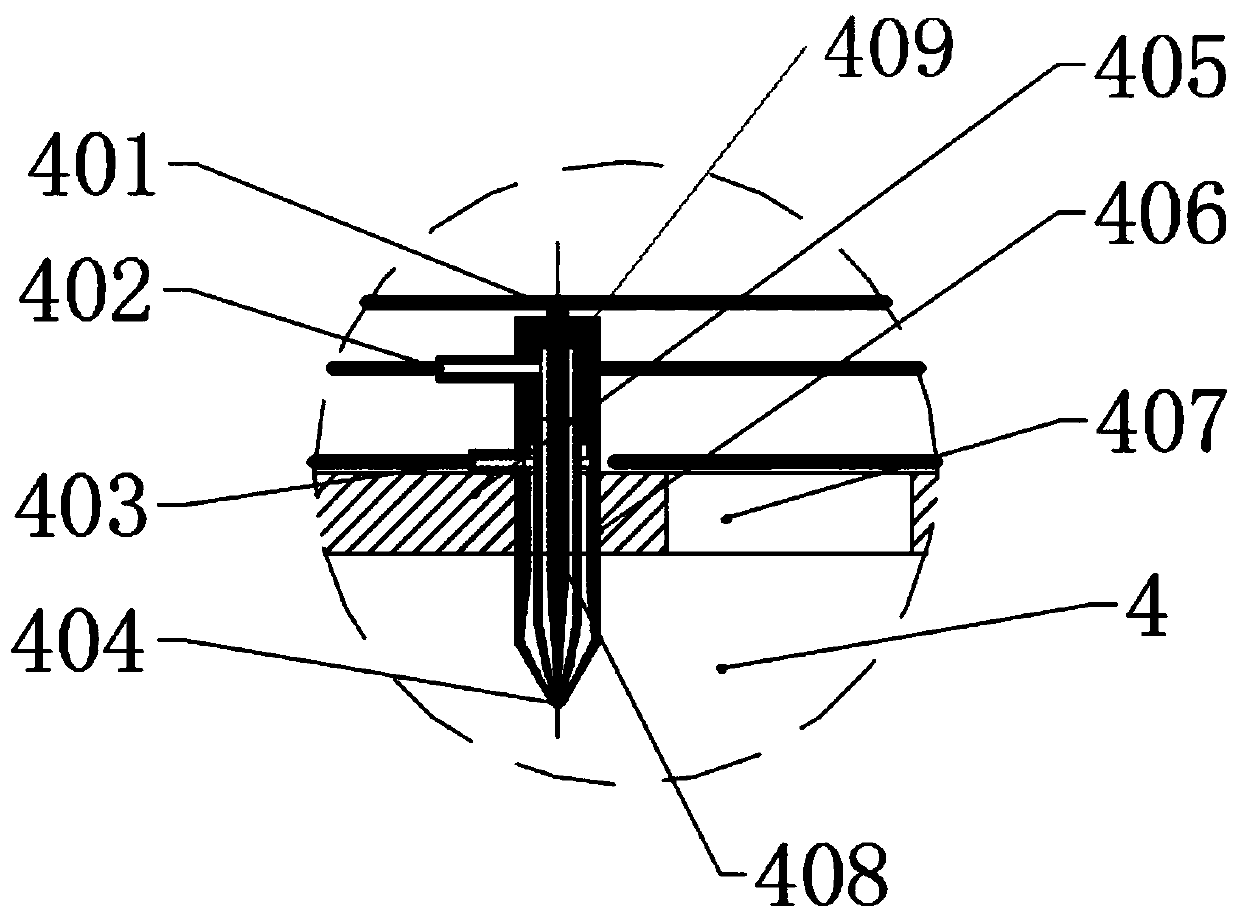

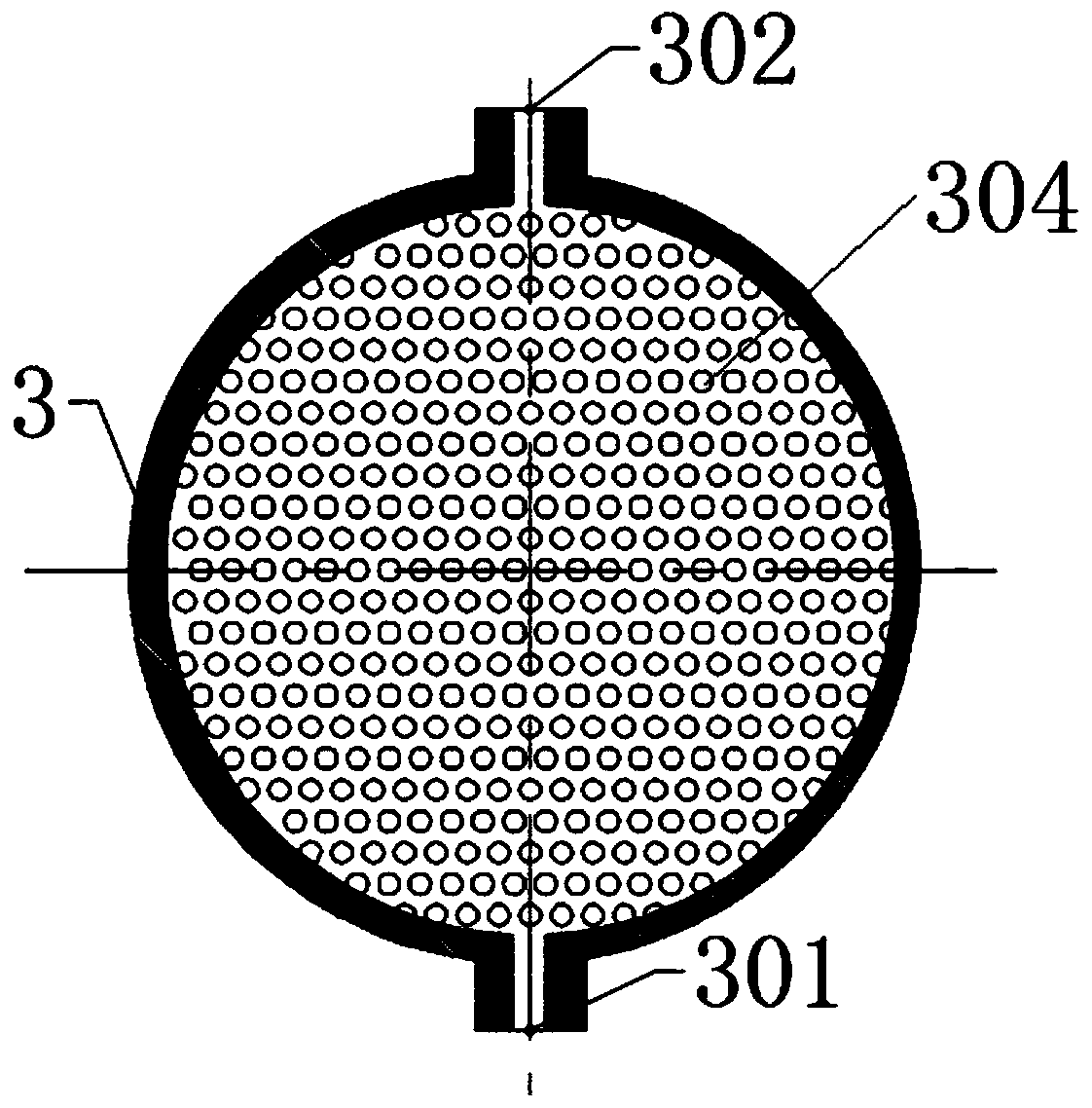

[0024] The present invention has designed a chimney waste gas dewhitening device utilizing electrostatic technology, such as figure 1 As shown, the cylindrical dewhitening device 2 is installed at the end of the chimney 1, and the condensing atomization device 3, the water collection tank 5 and the electrostatic atomization nozzle unit 4 are sequentially installed inside the dewhitening device 2 from bottom to top; the water collection tank 5 and The space between the electrostatic atomization nozzle units 4 is a dewhitening chamber 15 , and the space between the condensation atomization device 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com