Preparation method of black titanium dioxide-based composite material

A technology of black titanium dioxide and composite materials, which is applied in the field of preparation of black titanium dioxide-based composite materials, can solve the problems of poor adhesion between the catalyst and its carrier, long catalytic degradation cycle, harsh preparation conditions, etc., and achieve remarkable degradation effect, catalytic The effect of short degradation cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing a black titanium dioxide-based composite material, comprising the following steps:

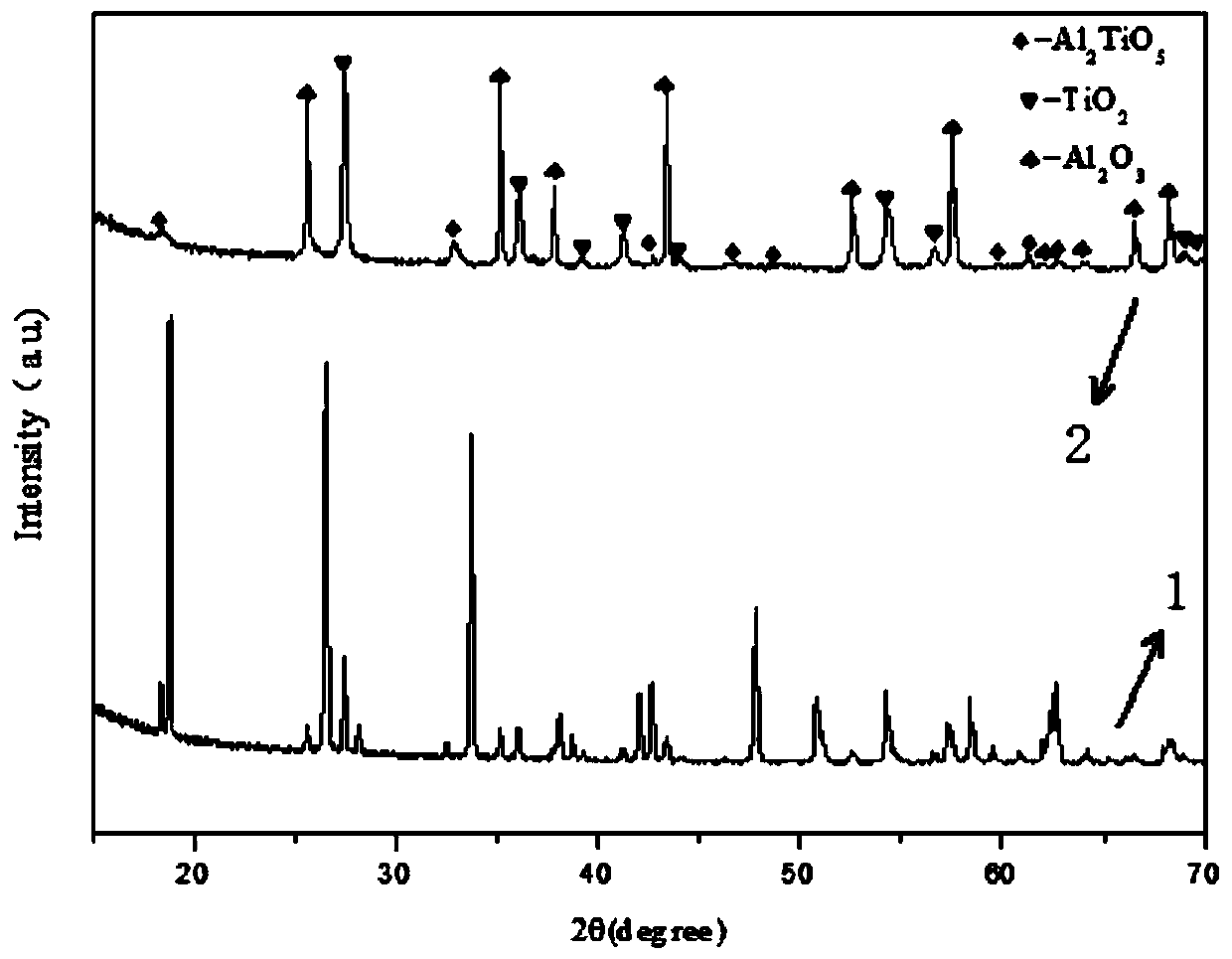

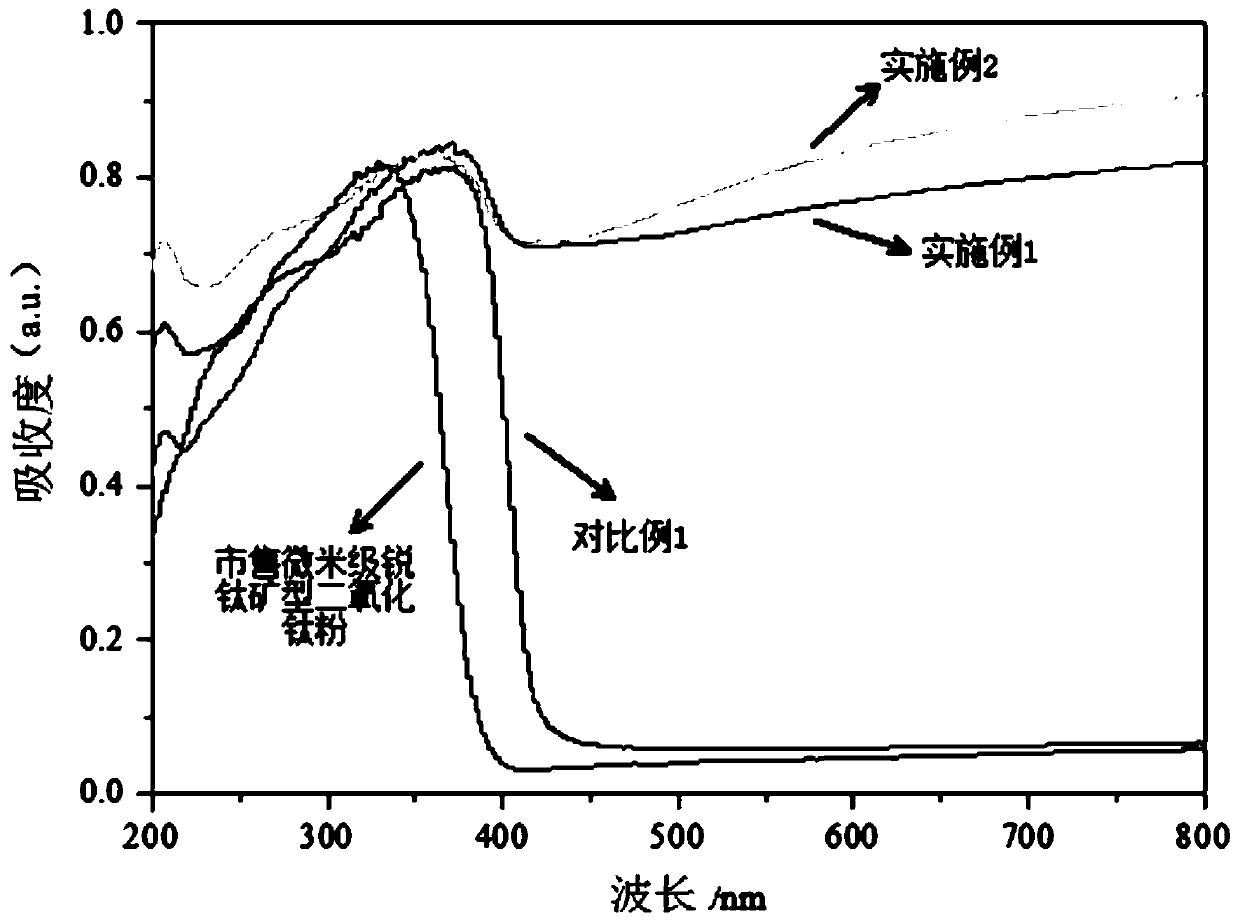

[0042] 1) Weigh 43.96g of solid titanium dioxide powder and 56.04g of alumina powder, use deionized water as solvent, mix titanium dioxide powder, alumina powder and deionized water to form a slurry, and use a planetary ball mill to mill for 30min (wherein titanium dioxide powder and oxide The total weight of aluminum powder, the mass ratio of zirconia ball mill and deionized water is 1:3:0.5), then the slurry is dried, and the dried slurry ball mill is put into an alumina crucible, and then the loaded The crucible with the slurry was calcined at 1450°C for 2 hours to obtain aluminum titanate powder, and then the synthesized aluminum titanate powder was ball milled for 60 minutes and sieved through 200 meshes to obtain a particle size of 0.66 μm aluminum titanate powder;

[0043] 2) The aluminum titanate powder with a particle size of 0.6...

Embodiment 2

[0046] This embodiment provides a method for preparing a black titanium dioxide-based composite material, comprising the following steps:

[0047] 1) Weigh 43.96g of solid titanium dioxide powder and 56.04g of alumina powder, use deionized water as solvent, mix titanium dioxide powder, alumina powder and deionized water to form a slurry, and use a planetary ball mill to mill for 30min (wherein titanium dioxide powder and oxide The total weight of aluminum powder, the mass ratio of zirconia ball mill and deionized water is 1:3:0.5), then the slurry is dried, and the dried slurry ball mill is put into an alumina crucible, and then the loaded The crucible with the slurry was calcined at 1450°C for 2 hours to obtain aluminum titanate powder, and then the synthesized aluminum titanate powder was ball milled for 60 minutes and sieved through 200 meshes to obtain a particle size of 0.66 μm aluminum titanate powder;

[0048] 2) The aluminum titanate powder with a particle size of 0.6...

Embodiment 3

[0051] This embodiment provides a method for preparing a black titanium dioxide-based composite material, comprising the following steps:

[0052] 1) Weigh 43.96g of solid titanium dioxide powder and 56.04g of alumina powder, use deionized water as solvent, mix titanium dioxide powder, alumina powder and deionized water to form a slurry, and use a planetary ball mill to mill for 30min (wherein titanium dioxide powder and oxide The total weight of aluminum powder, the mass ratio of zirconia ball mill and deionized water is 1:3:0.5), then the slurry is dried, and the dried slurry ball mill is put into an alumina crucible, and then the loaded The crucible with the slurry was calcined at 1450°C for 2 hours to obtain aluminum titanate powder, and then the synthesized aluminum titanate powder was ball milled for 60 minutes and sieved through 200 meshes to obtain a particle size of 0.66 μm aluminum titanate powder;

[0053] 2) The aluminum titanate powder with a particle size of 0.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com