Shoulder strap machine

A shoulder strap and frame technology, applied in the field of sewing processing equipment, can solve problems such as easy slipping and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

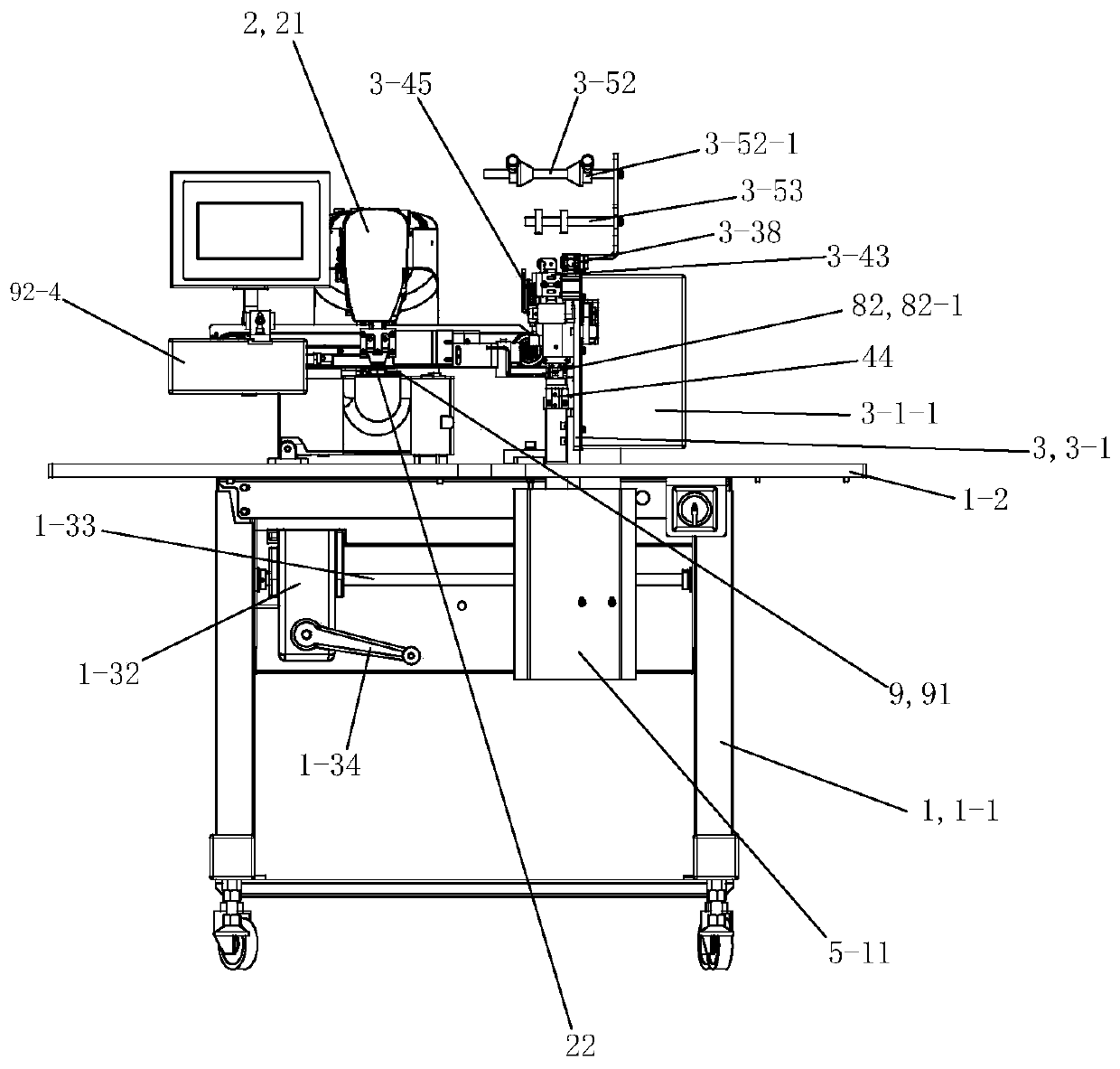

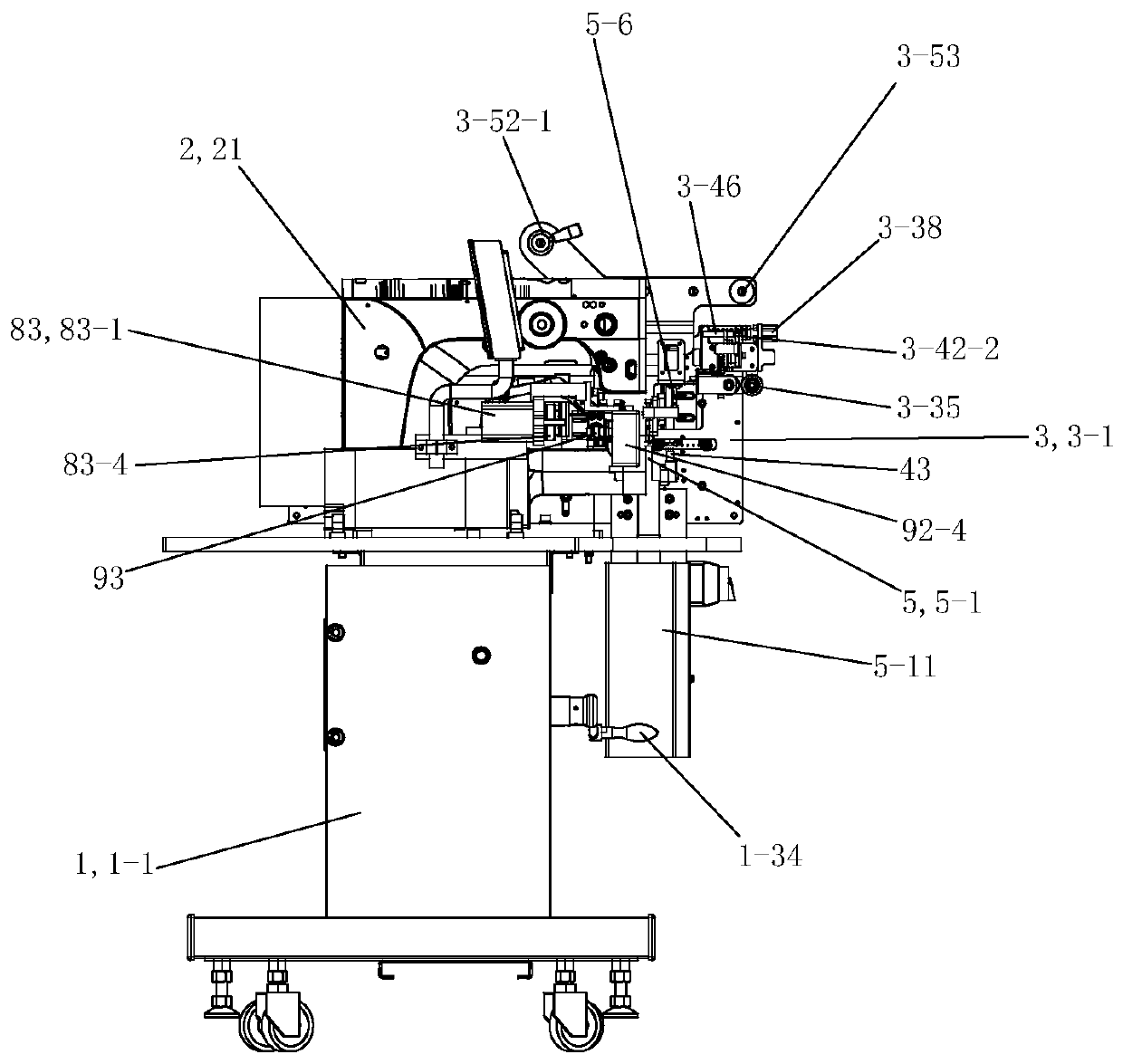

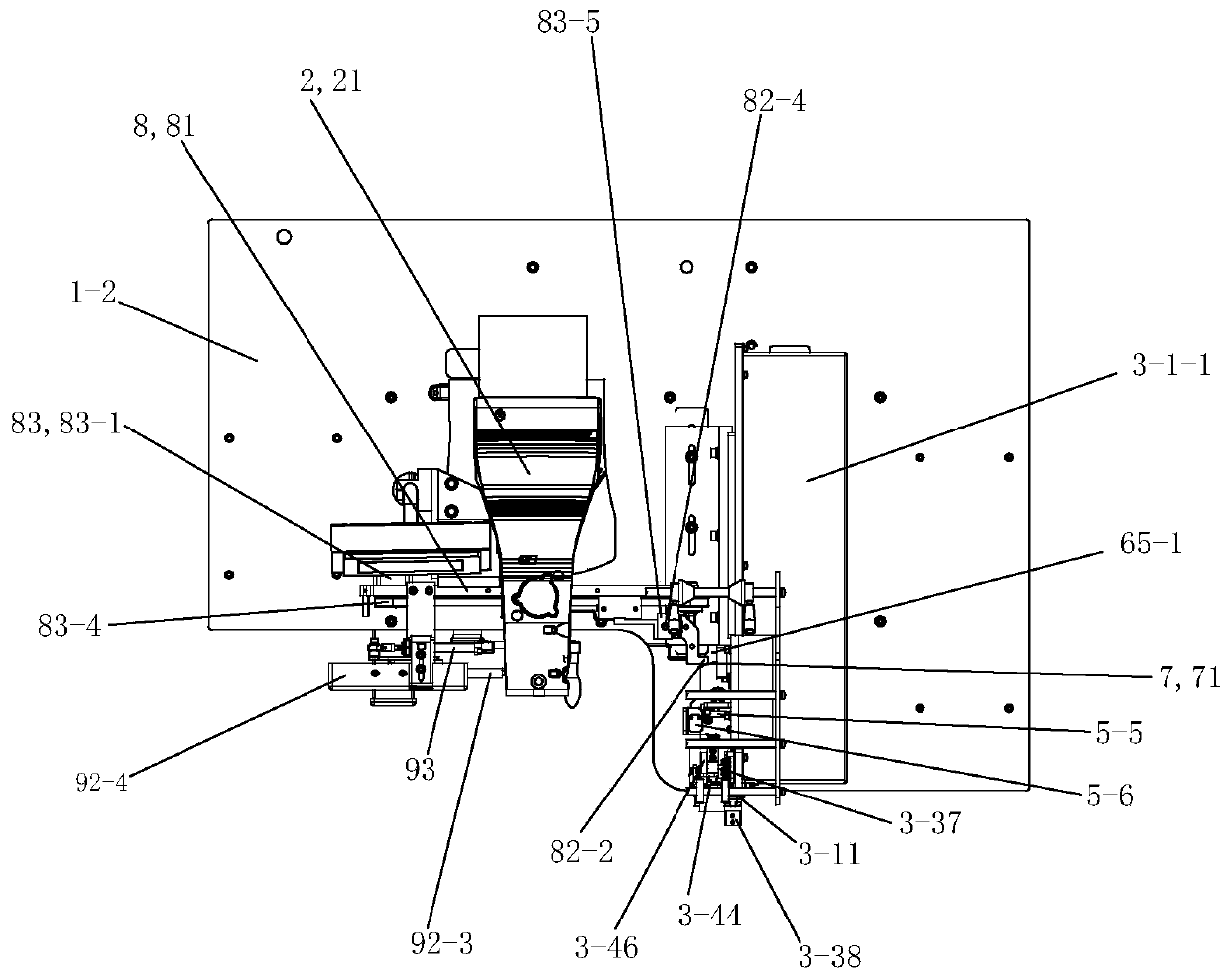

[0067] See Figure 1 to Figure 19 , the shoulder belt machine of the present invention includes a workbench assembly 1, a sewing assembly 2, a feeding assembly 3, a first clamping assembly 4, a cutting assembly 5, a pulling assembly 6, an overturning assembly 7, a feeding assembly 8 and a folding assembly 9.

[0068] See Figure 1 to Figure 8 , The worktable assembly 1 includes a frame 1-1, a worktable 1-2 and a table lifting mechanism 1-3. The worktable 1-2 is fixedly arranged on the frame 1-1 by the platform lifting mechanism 1-3, and the height of the working platform 1-2 can be adjusted by the platform lifting mechanism 1-3. The platen lifting mechanism 1-3 comprises a lifting connecting frame 1-31, a worm gear box 1-32, a worm shaft 1-33, a crank handle 1-34, a gear 1-35 and a rack 1-36. The left part and the right part of the lifting connecting frame 1-31 are respectively slidably arranged on the left part and the right part of the frame 1-1 along the up and down dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com