Filling grouting method of vertical fractures of slope face rock body

A rock mass, vertical technology, applied in excavation, climate change adaptation, construction, etc., can solve problems affecting construction quality, etc., and achieve the effects of accelerating ecological environment improvement, accelerating management and development, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0106] The rock mass is taken as an example of the sandstone block, and the slurry is a high polymer slurry. The high polymer is generally a two-component polyurethane high polymer grouting material with self-expanding characteristics. This high polymer grouting material has its own Expansion characteristics, the free expansion rate in the air can reach 25-30 times.

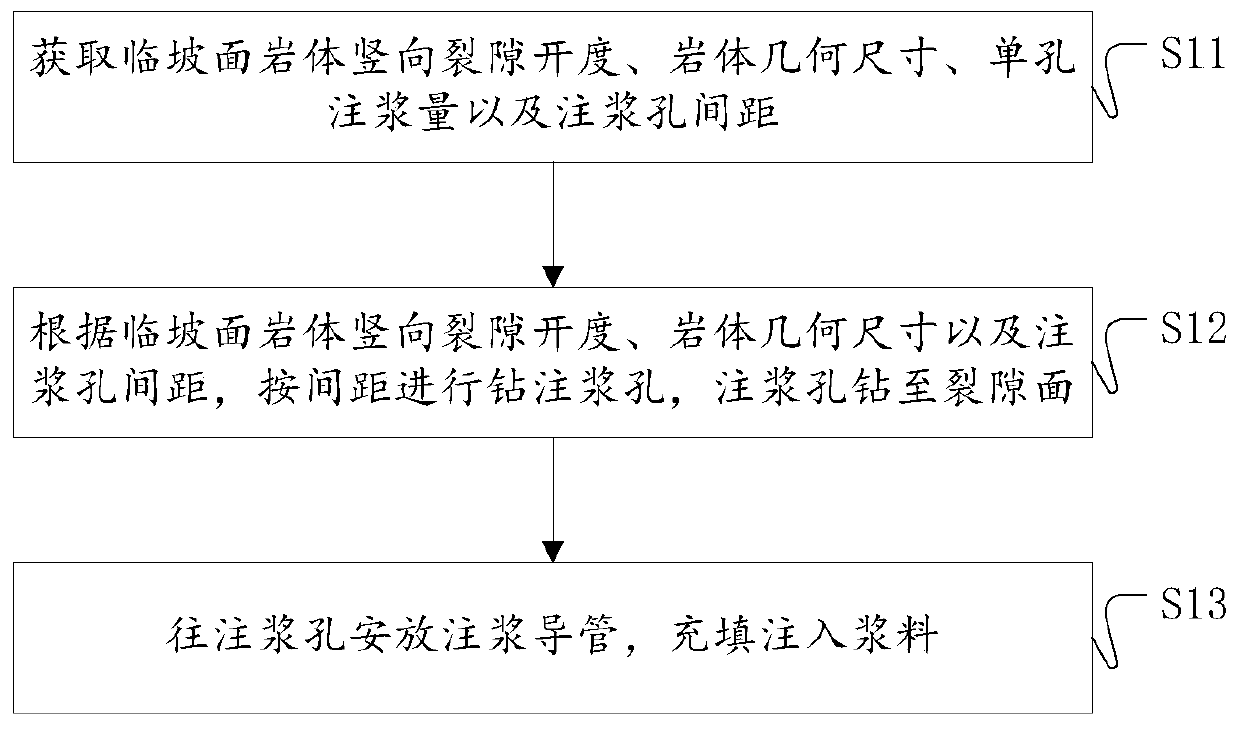

[0107] For a Pisha sandstone block with vertical cracks on the slope, it is necessary to fill the vertical cracks with polymer grouting to block the infiltration channel of water flow, so as to avoid block-like gravity erosion. The polymer grouting method The implementation steps are as follows:

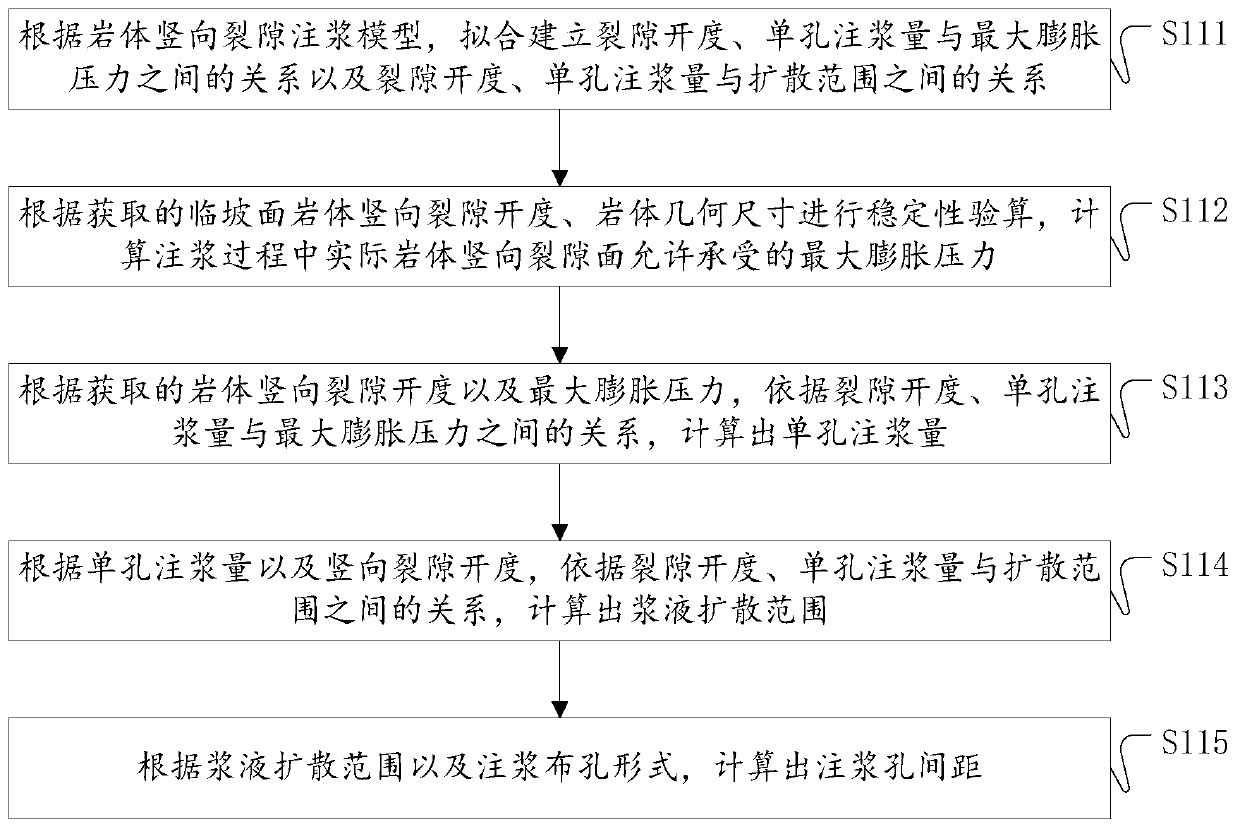

[0108] A. Design of polymer grouting parameters for vertical fractures in Pisha sandstone, including:

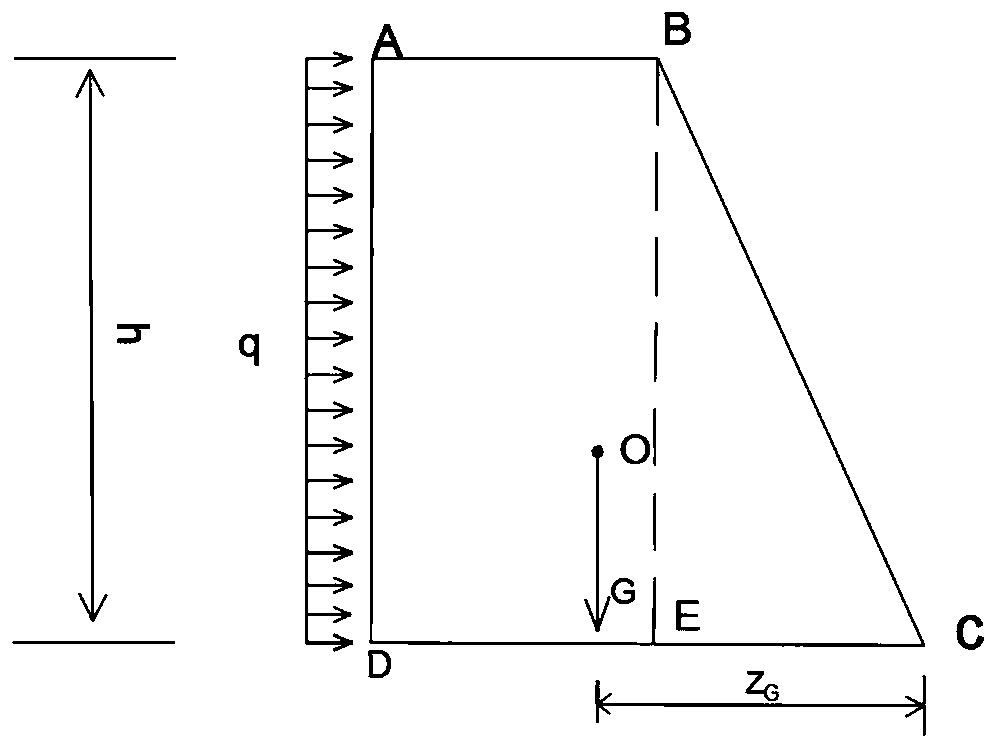

[0109] A1. Determine the geometric dimensions of vertical fissures and sandstone blocks on the facing slope through on-site investigations, mainly including the opening and height of vertical fissures and the cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com