An aluminum-steel combined rail vehicle brake disc

A rail vehicle, brake disc technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the requirements of reducing weight, the brake disc can not meet the problems of higher temperature and thermal stress at the same time, Achieve the effect of improving the life of the brake disc, reducing the temperature, and good high temperature wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

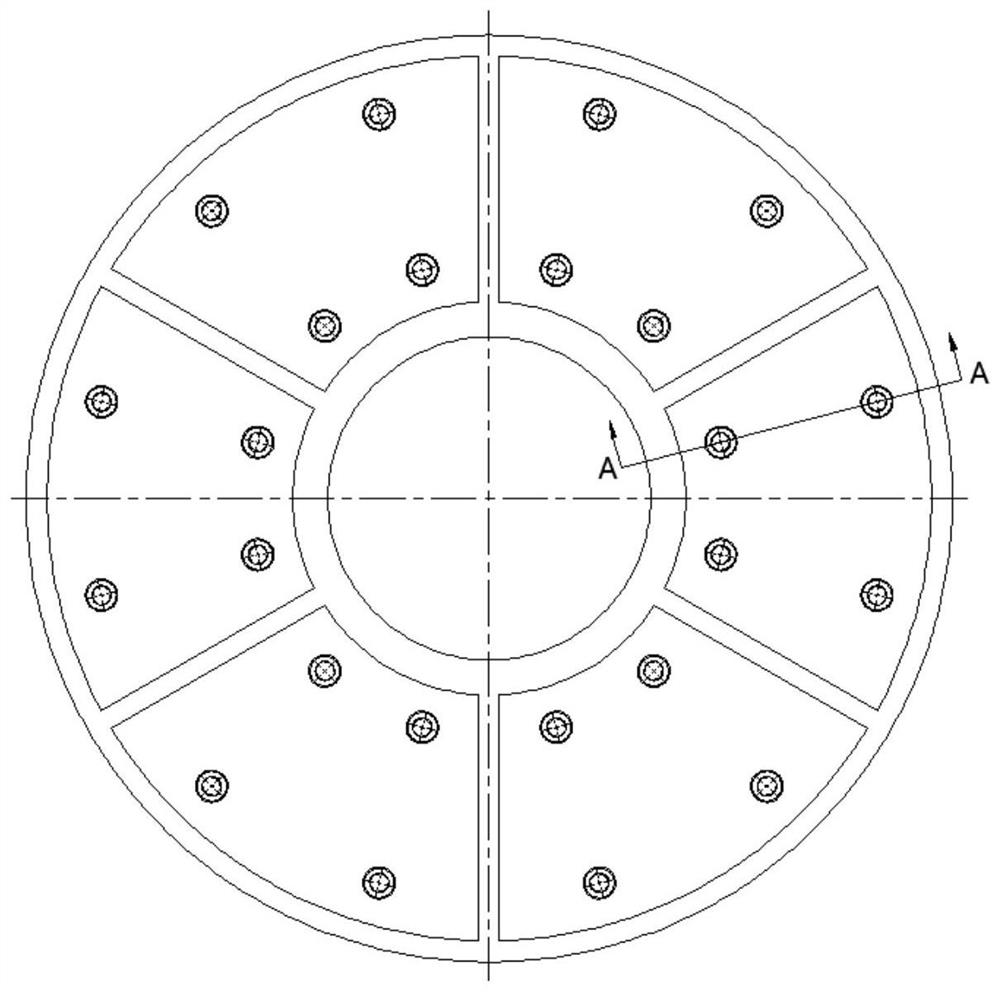

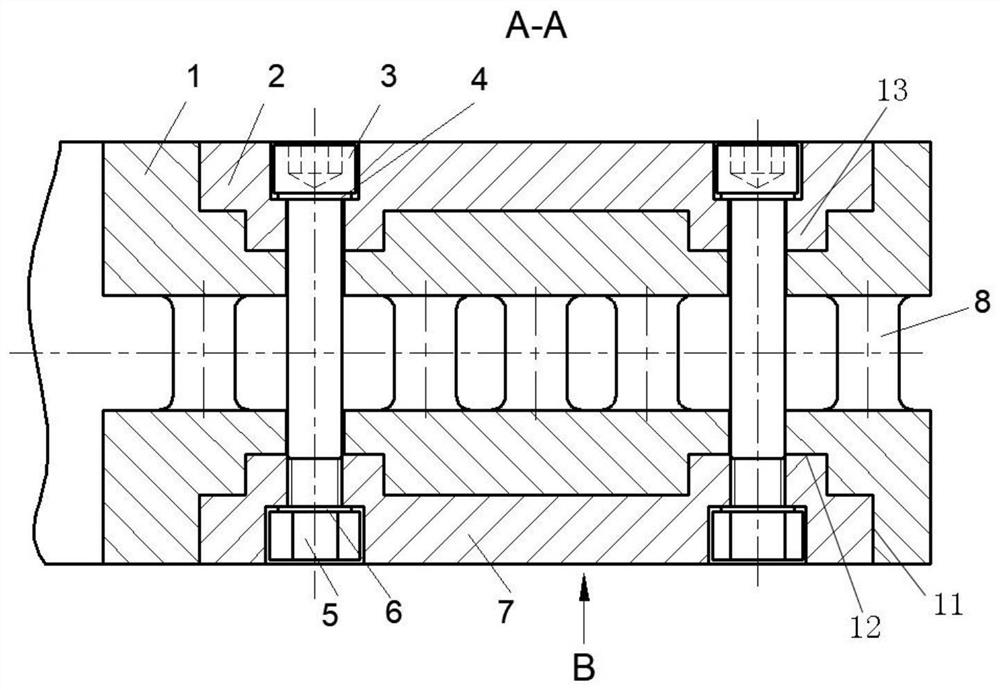

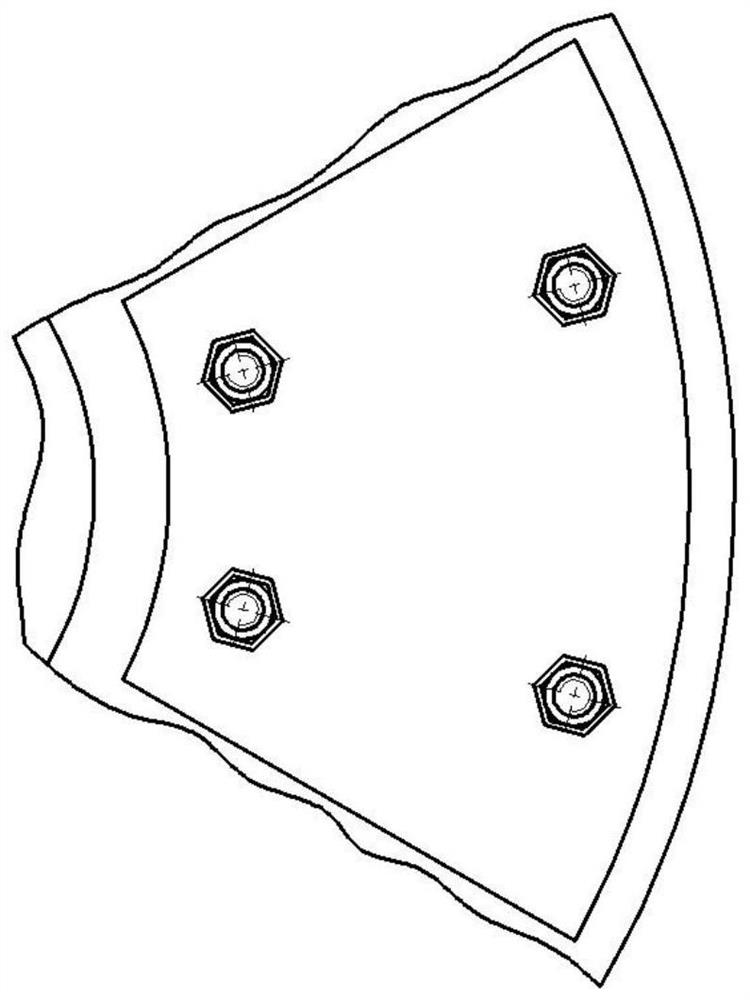

[0035] Such as Figure 1-5 As shown, the present invention provides an aluminum-steel combined rail vehicle brake disc, comprising a brake disc main body 1 and an outer layer plate, the brake disc main body 1 is made of aluminum alloy, and the outer layer plate is made of Made of alloy steel or cast iron; the brake disc main body 1 is provided with a number of heat dissipation ribs; the upper surface and the lower surface of the brake disc main body 1 are respectively provided with fan-shaped grooves 11; the outer plate is fixedly installed on the In the fan-shaped groove 11.

[0036] Further, the brake disc main body 1 is made of high-strength aluminum alloy.

[0037] Further, 3 to 8 fan-shaped grooves 11 are respectively provided on the upper surface and the lower surface of the brake disc main body 1, and the interval between two adjacent fan-shaped grooves 11 is 5 mm to 15 mm, which is considered The difference between the thermal expansion coefficients of steel and alum...

Embodiment 2

[0053] On the basis of Embodiment 1, six fan-shaped grooves 11 are arranged in an axially symmetrical distribution on the upper surface and the lower surface of the brake disc main body 1, and the interval between two adjacent fan-shaped grooves 11 is 10 mm. , the depth of the fan-shaped groove 11 is 15mm.

[0054] Further, the heat dissipation ribs are cylindrical.

[0055] Further, the boss 13 is cylindrical with a height of 8mm.

[0056] Further, the positioning step 12 is arranged on the fan-shaped groove 11 at a position corresponding to the bolt 3 .

Embodiment 3

[0058] Such as Figure 6-7 As shown, the difference between this embodiment and Embodiment 1 is that the brake disc can be used for foundation braking on urban rail trains, and the outer plate is made of compacted graphite cast iron.

[0059] Further, the outer plate is provided with screw holes, and the inside of the heat dissipation rib at the position corresponding to the screw holes on the main body of the brake disc is provided with threaded holes, and the brake disc also includes screws 9 through which the screws 9 pass through. Screw into the threaded hole through the screw hole, so that the outer layer board is fixedly installed in the fan-shaped groove 11 .

[0060] Further, the heat dissipation ribs at the positions corresponding to the screw holes on the brake disc main body 1 are heat dissipation ribs II10, and the heat dissipation ribs at other positions are heat dissipation ribs I8, and the heat dissipation ribs II10 are thicker than the heat dissipation ribs I8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com