Novel cement kiln denitration and desulfurization catalytic system with double-disc paddle hourglass reversing function

A catalytic system and cement kiln technology, applied in the direction of furnace type, improvement of process efficiency, chemical instruments and methods, etc., can solve problems such as loss of flatness, pitted blades, large consumption of internal parts, etc., to improve quality, compact particles The effect of simple consistency and flatness, and improved particle saturation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

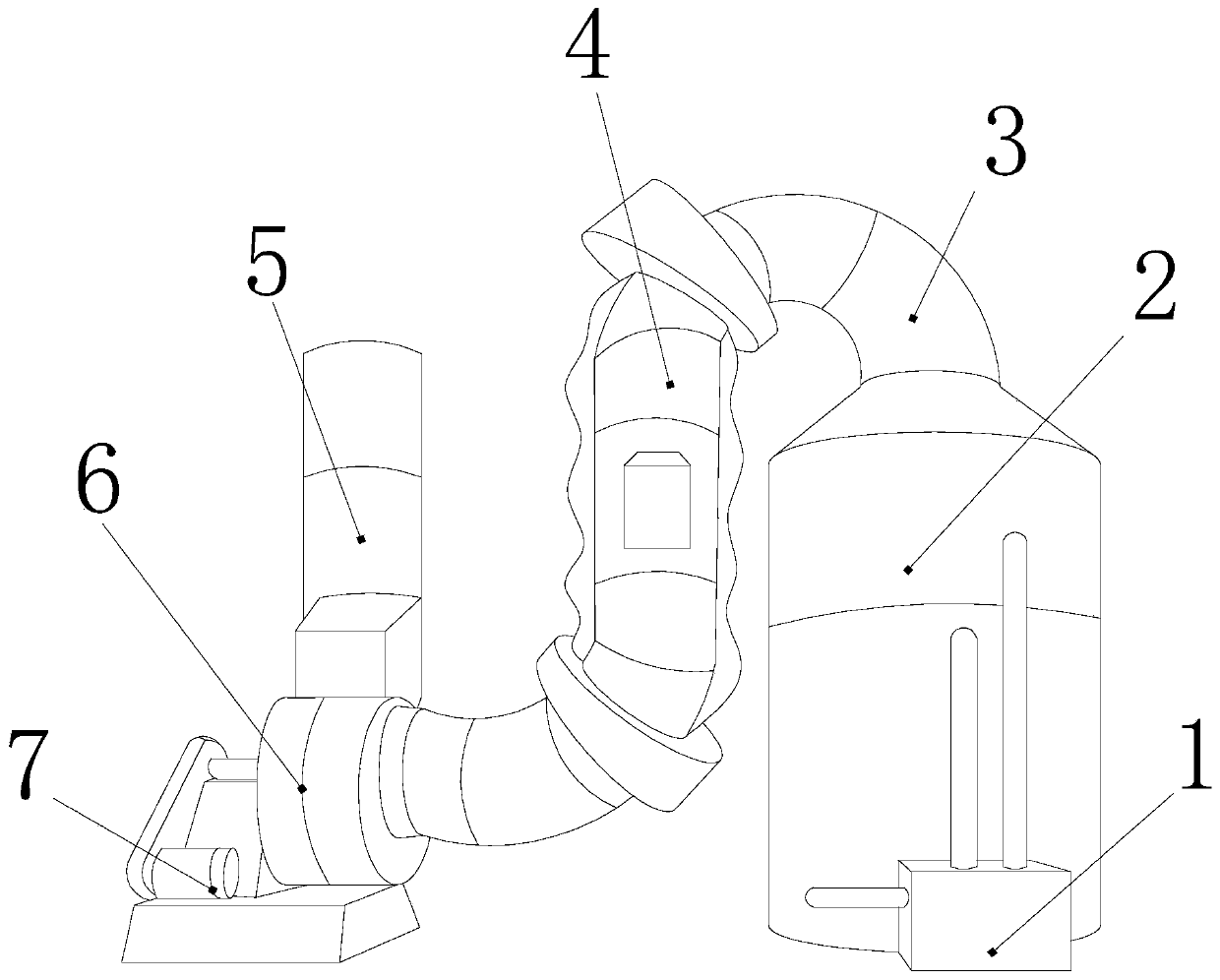

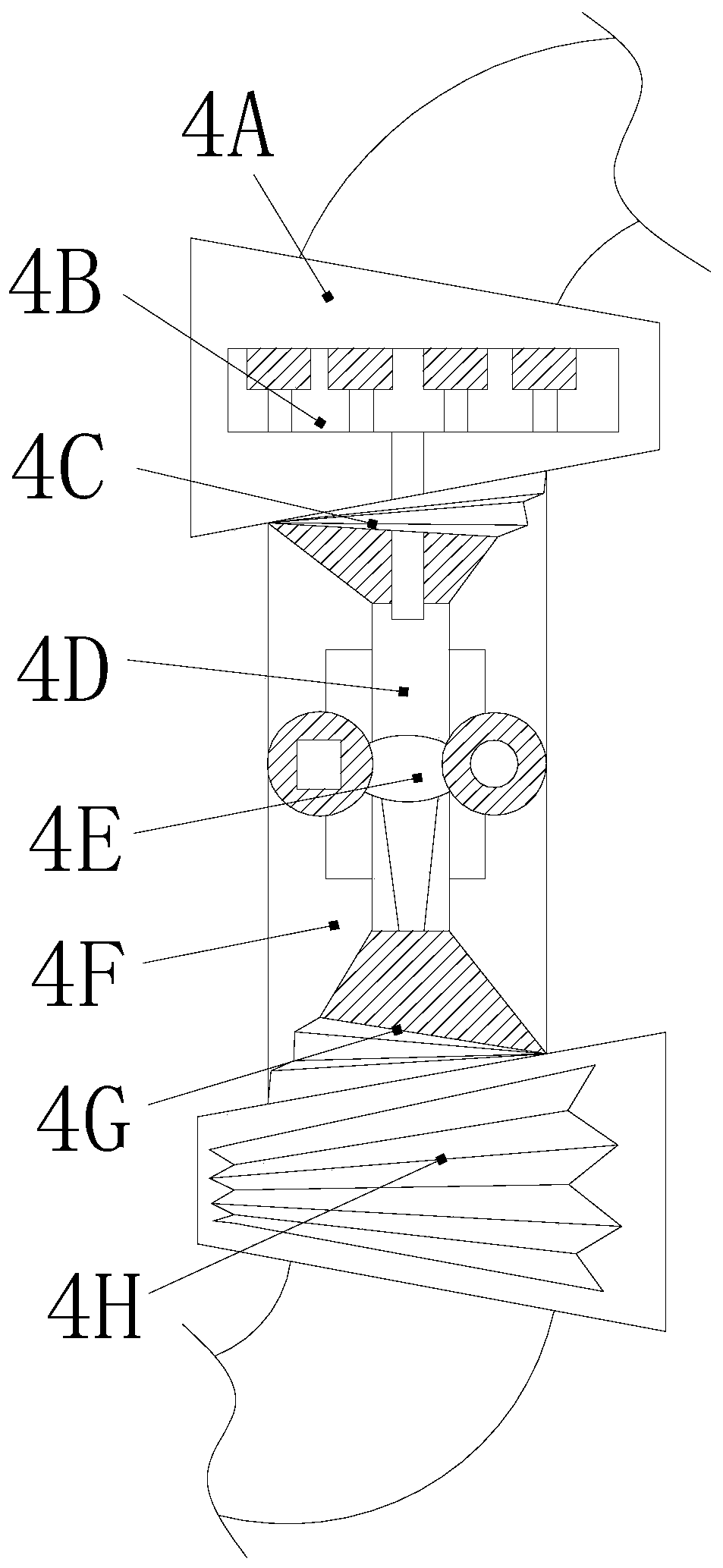

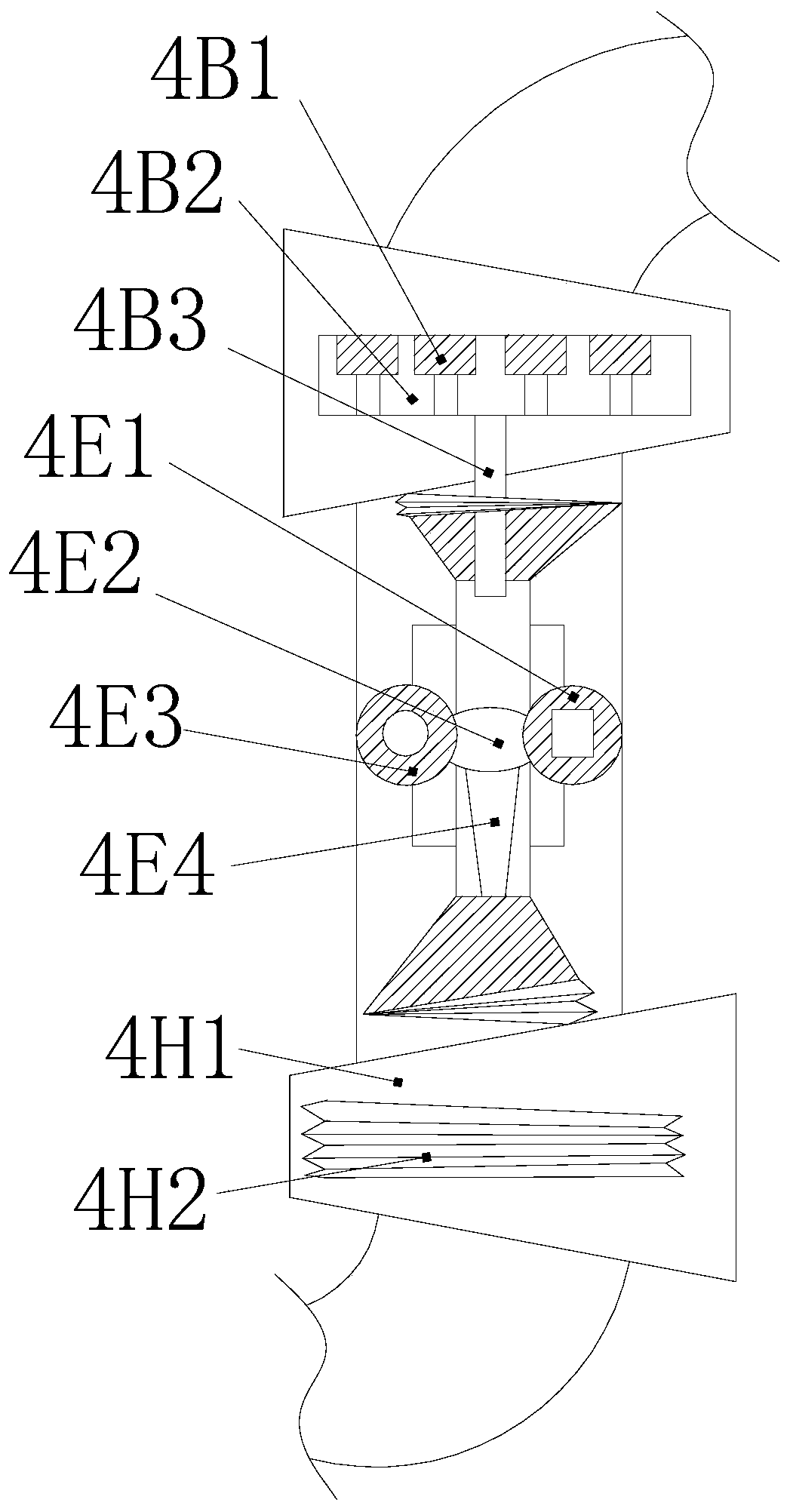

[0032] see Figure 1-Figure 7 , the present invention provides a novel double-disk paddle hourglass reversed cement kiln denitrification and desulfurization catalytic system, the structure of which includes: branch storage tank 1, lime storage tank 2, curved pipe 3, double-disk long tube device 4, cement powder cylinder 5, rotary grinding tank 6, chain belt motor 7, the double-disk long cylinder device 4 is fastened together with the curved pipe 3 and communicates with each other, and the curved pipe 3 is provided with two and respectively inserted in the lime On the top of the storage tank 2 and on the right side of the rotary grinding tank 6, the branch storage box 1 is close to the front side of the lime storage tank 2, and the cement powder cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com