A method for producing alc boards with multiple lengths

A multi-length, quicklime technology, applied in chemical instruments and methods, cement mixing devices, auxiliary molding equipment, etc., can solve the problems of difficult cutting of steel bars, time-consuming and labor-intensive, oblique deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

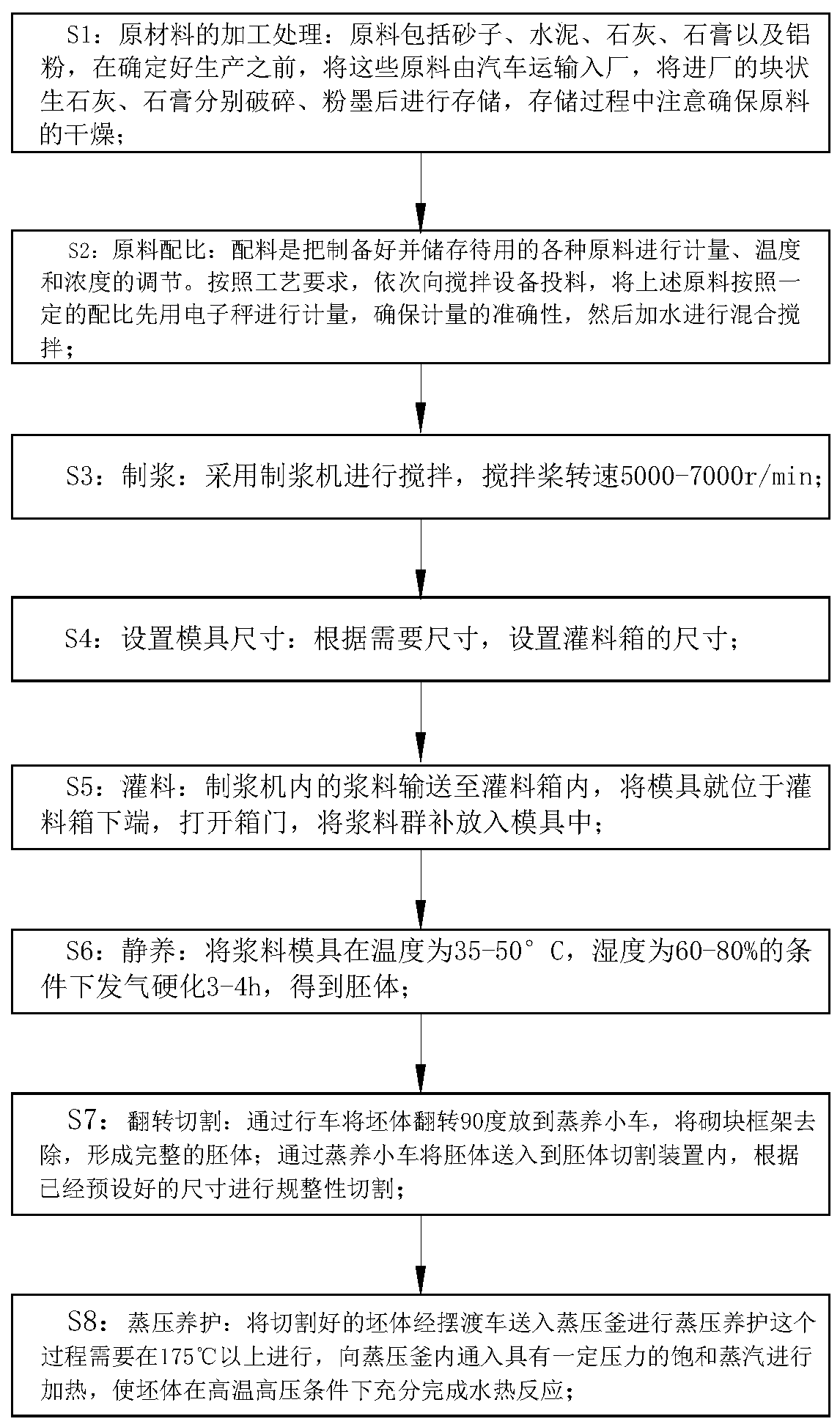

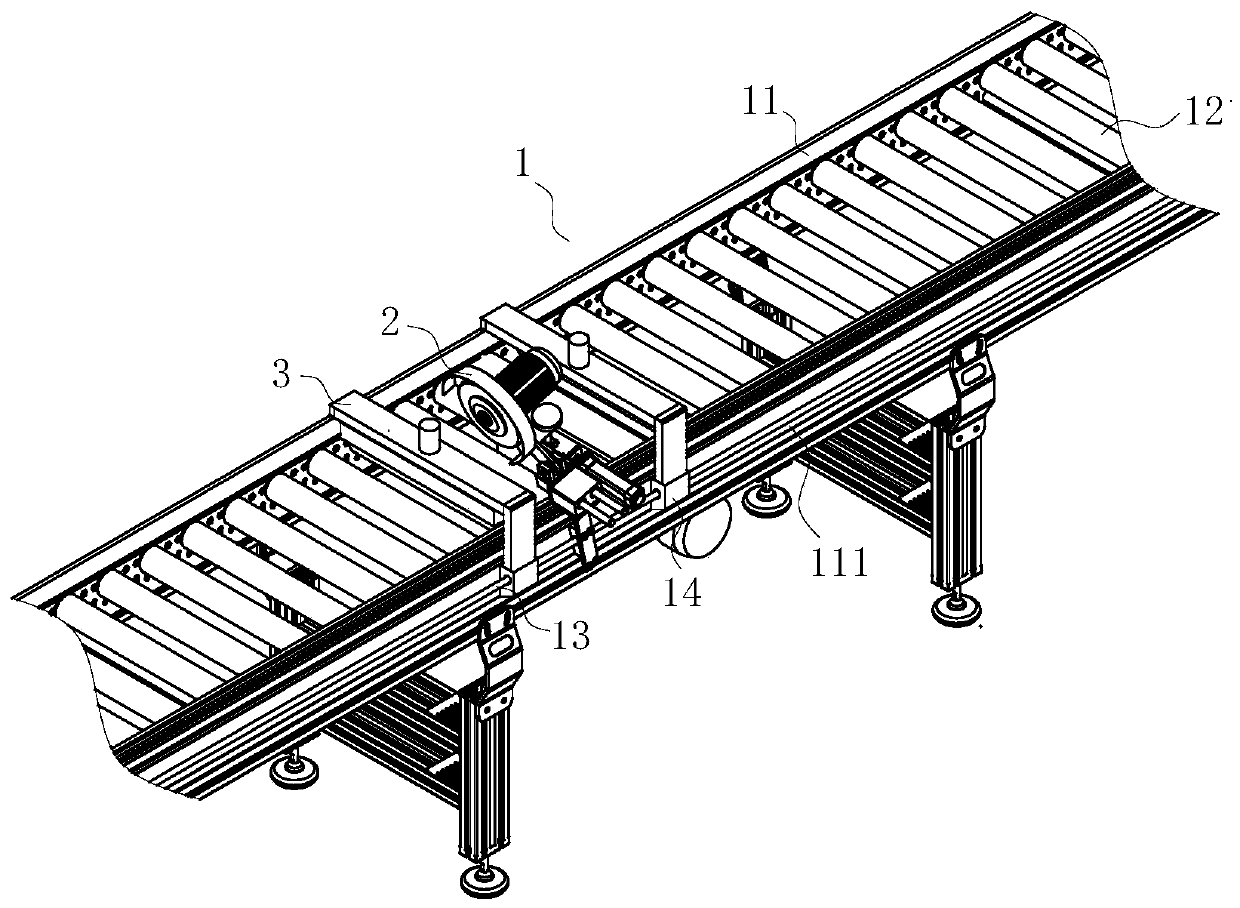

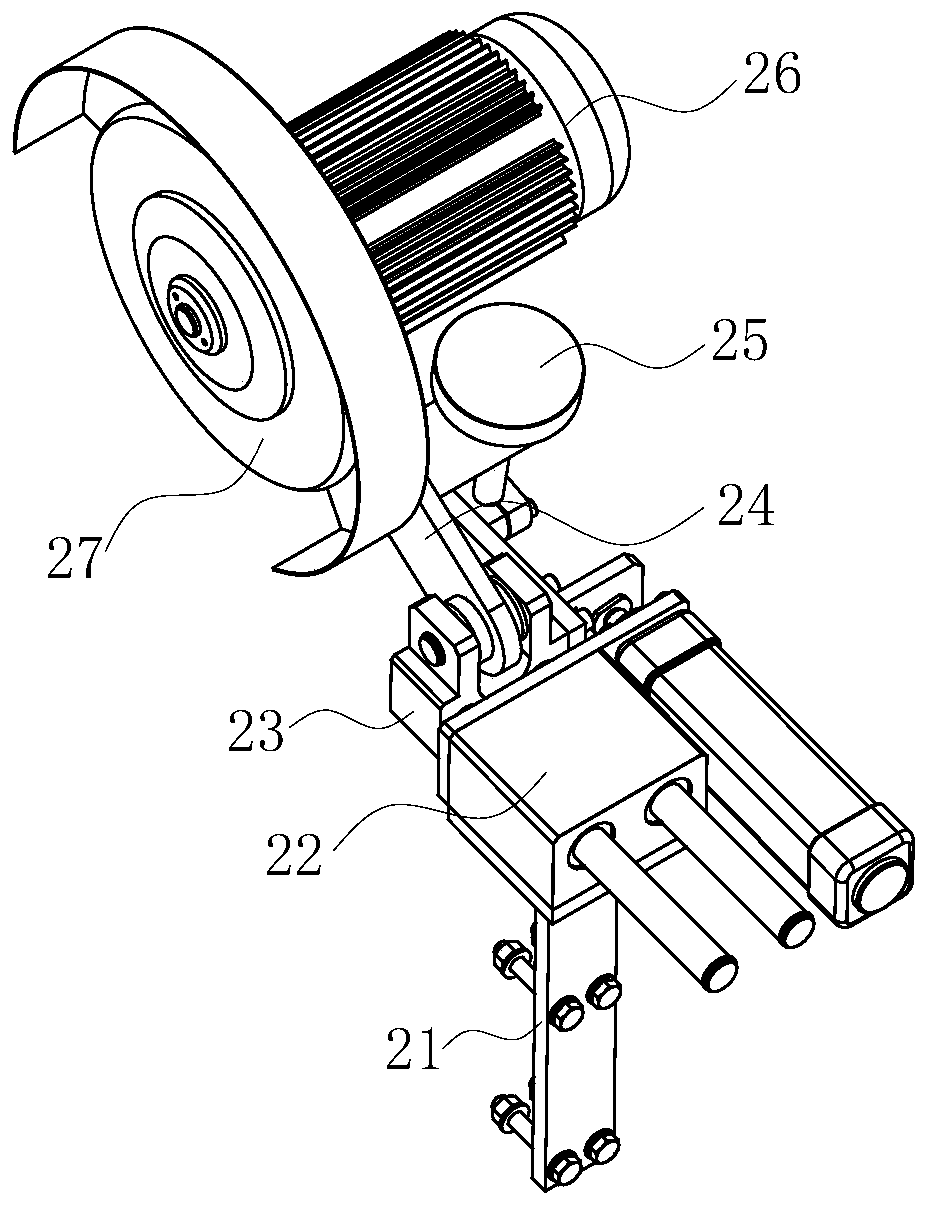

[0037] use Figure 1-Figure 7 A method for producing an ALC plate with multiple lengths according to an embodiment of the present invention is described as follows.

[0038] Such as Figure 1-Figure 7 Shown, a kind of method for multi-length production ALC plate of the present invention, the method may further comprise the steps:

[0039] S1: Processing of raw materials: Raw materials include fly ash, cement, lime, gypsum and aluminum powder. Before the production is confirmed, these raw materials are transported into the factory by car, and the lump quicklime and gypsum entering the factory are broken into powder respectively. After storage, pay attention to ensure that the raw materials are dry during storage;

[0040] S2: Raw material ratio: batching is to measure, adjust the temperature and concentration of various raw materials that have been prepared and stored for use, and feed them to the mixing equipment in turn according to the process requirements. , to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com