A core-shell type sulphoaluminate cement-based high-strength lightweight aggregate and its preparation method

A technology of sulphoaluminate cement and lightweight aggregate, which is applied in the field of building materials, can solve the problems of inconspicuous thermal insulation effect and insufficient strength, and achieve the effects of improving the setting time too fast, enhancing the bearing capacity, and being widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

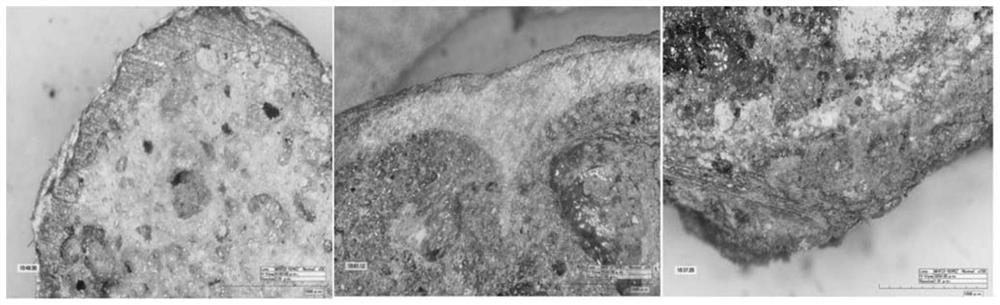

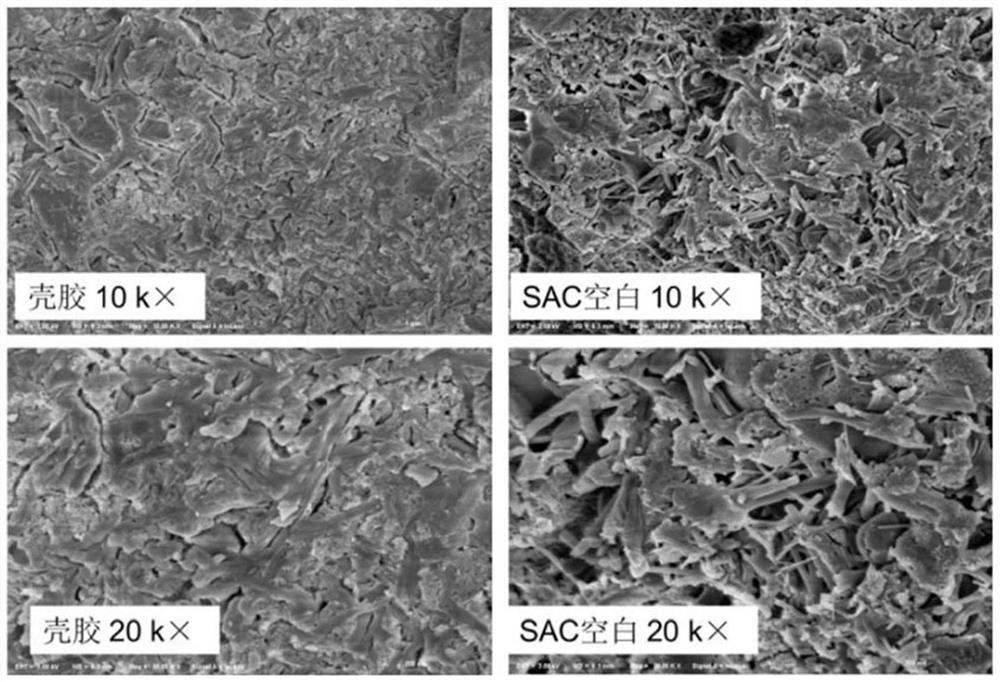

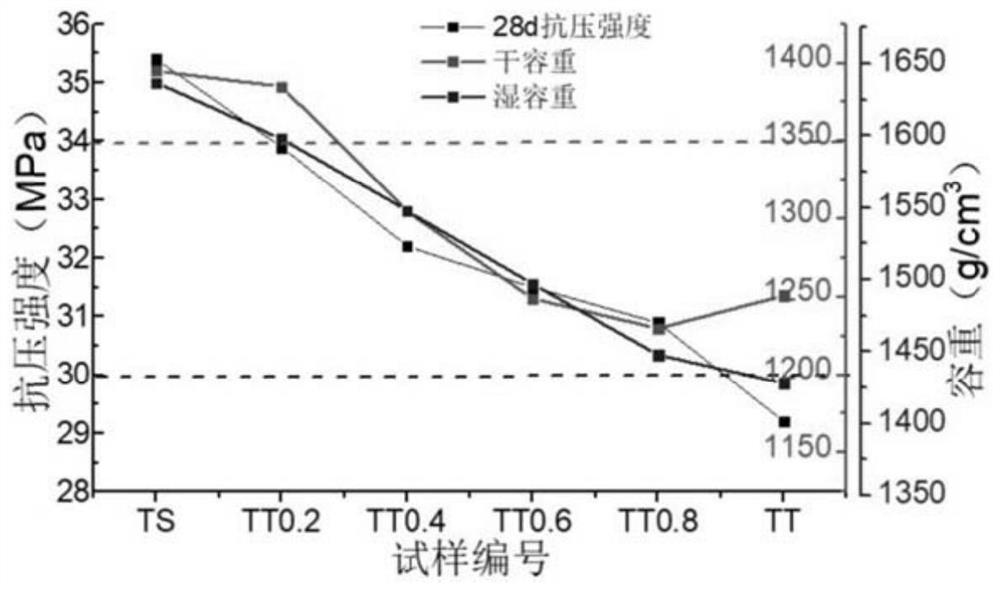

[0038] A core-shell type sulphoaluminate cement-based high-strength lightweight aggregate, the specific preparation method is as follows:

[0039] 1) Weigh the raw material components according to the following proportions by mass: 100 parts of sulphoaluminate cement, 5 parts of ordinary Portland cement, 5 parts of fly ash, 6 parts of silica fume, 1 part of water reducer, and mix according to the proportion The above-mentioned raw materials are placed in a mixer and stirred evenly, and then according to the water-binder ratio of 0.38, the amount of water of standard consistency is added at room temperature, and the stirring is continued until uniform to obtain a sulphoaluminate cement-based cementitious material;

[0040] 2) Soak the fly ash ceramsite in tap water and keep the liquid level 5cm±0.5mm above the ceramsite particles. After pre-wetting treatment for 1 hour to reach the saturated water absorption state, place it in a sugar coating pan, and then spray the sulphoalumina...

Embodiment 2

[0043] A core-shell type sulphoaluminate cement-based high-strength lightweight aggregate, the specific preparation method is as follows:

[0044] 1) Weigh the raw material components according to the following proportions by mass: 100 parts of sulphoaluminate cement, 10 parts of ordinary Portland cement, 15 parts of fly ash, 2 parts of silica fume, 1 part of water reducer, and The above-mentioned raw materials are placed in a mixer and stirred evenly, and then according to the water-binder ratio of 0.38, the amount of water of standard consistency is added at room temperature, and the stirring is continued until uniform to obtain a sulphoaluminate cement-based cementitious material;

[0045] 2 Soak the fly ash ceramsite in tap water and keep the liquid level 5cm±0.5mm above the ceramsite particles. After pre-wetting treatment for 1 hour to reach the saturated water absorption state, place it in a sugar coating pan, and then spray the sulphoaluminate cement-based cementitious ...

Embodiment 3

[0048] A core-shell type sulphoaluminate cement-based high-strength lightweight aggregate, the specific preparation method is as follows:

[0049] 1) Weigh the raw material components according to the following proportions by mass: 100 parts of sulphoaluminate cement, 15 parts of ordinary Portland cement, 10 parts of fly ash, 6 parts of silica fume, 1 part of water reducer, and The above-mentioned raw materials are placed in a mixer and stirred evenly, and then according to the water-binder ratio of 0.38, the amount of water of standard consistency is added at room temperature, and the stirring is continued until uniform to obtain a sulphoaluminate cement-based cementitious material;

[0050] 2) Soak the fly ash ceramsite in tap water and keep the liquid level 5cm±0.5mm above the ceramsite particles. After pre-wetting treatment for 1 hour to reach the saturated water absorption state, place it in a sugar coating pan, and then spray the sulphoaluminate cement-based cementitious...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com