Preparation method of lithium-aluminum hydrotalcite derivatives applied to sulphate aluminium cement based material with big water cement ratio

A technology of ash ratio sulfoaluminate and cement-based materials, which is applied in the field of preparation of lithium aluminum hydrotalcite derivatives, can solve the problems that the compressive strength cannot meet the requirements, and achieve high compressive strength, good repeatability, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

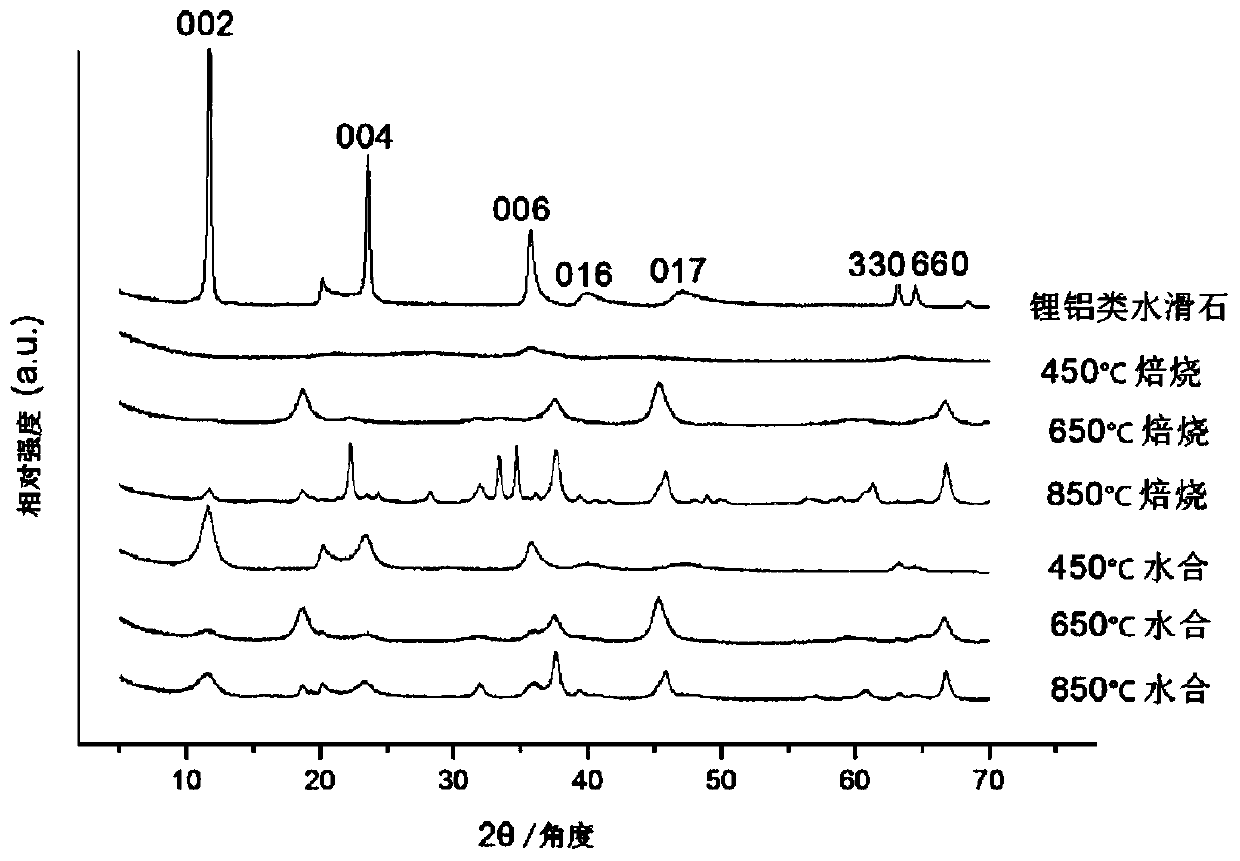

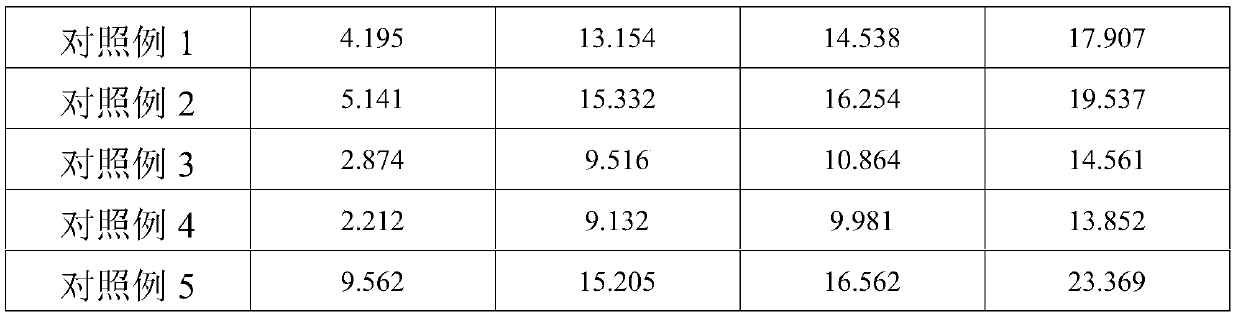

[0033] The preparation method of the lithium-aluminum hydrotalcite derivatives provided by the present invention is firstly to prepare a mixed salt solution and a mixed alkali solution respectively, and react rapidly after the two are mixed, and then undergo heating and reflux crystallization, and post-treatment to obtain lithium-aluminum hydrotalcite , and finally roasted at high temperature to obtain roasted lithium aluminum hydrotalcite derivatives, and then hydrated to obtain hydrated lithium aluminum hydrotalcite derivatives. The preparation method is simple and repeatable; the present invention derives lithium aluminum hydrotalcite As an early strength agent added to the sulphoaluminate cement-based material with a large water-cement ratio, it can significantly improve the early compressive strength of the sulphoaluminate cement-based material under the condition of a large water-cement ratio. Shrinkage occurs, which solves the problem that the compressive strength of exi...

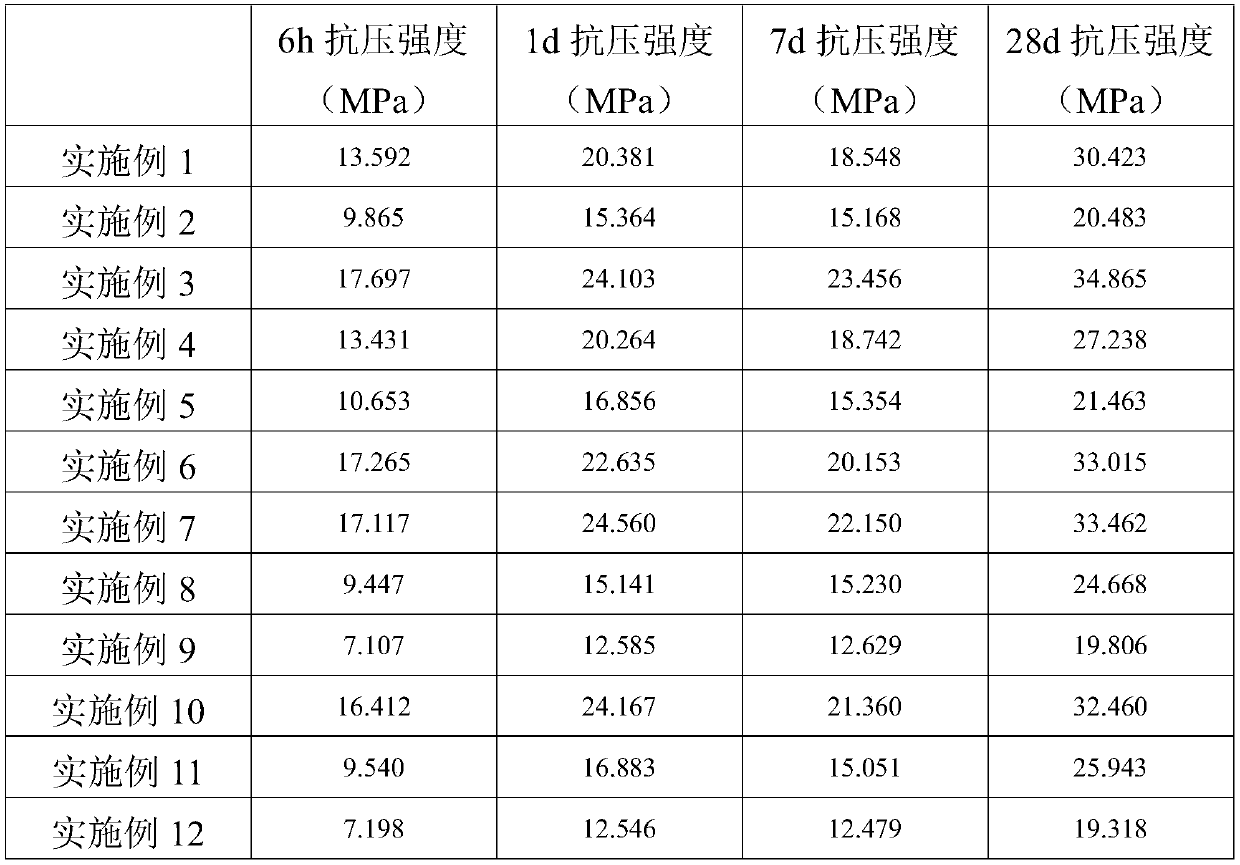

Embodiment 1

[0057] The preparation method of lithium aluminum hydrotalcite derivatives in this embodiment comprises the following steps:

[0058] S1, weigh 27.58g LiNO respectively 3 and 37.574g Al(NO 3 ) 3 ﹒ 9H 2 O was dissolved in deionized water to prepare a 250ml mixed salt solution; then weigh 16g of NaOH and 2.650g of NaOH 2 CO 3 Dissolve in deionized water to prepare 250ml mixed alkali solution;

[0059] S2, the 250ml mixed salt solution and the 250ml mixed alkali solution prepared in step S1 are quickly introduced into the full back-mixing explosive nucleation reactor at the same rate of addition and mixed, and reacted rapidly for 3 minutes to obtain a mixed slurry;

[0060] S3, transferring the mixed slurry obtained in step S2 into a reaction kettle, heating to reflux at 95° C. for 5 h, and centrifuging and washing with deionized water until neutral to obtain lithium aluminum hydrotalcite (LiAl-LDH);

[0061] S4, drying the LiAl-LDH obtained in step S3 at 50° C., grinding ...

Embodiment 2

[0066] In the present embodiment, in step S1, weigh 27.58g Li respectively 2 CO 3 and 37.574g Al 2 (SO 4 ) 3 ﹒ 18H 2 O was dissolved in deionized water to prepare a 250ml mixed salt solution; then weigh 16g of KOH and 2.650g of K 2 CO 3 Dissolve in deionized water to prepare 250ml mixed alkali solution;

[0067] In step S4, the calcination at 650° C. was replaced and the temperature was maintained for 3 h to obtain the calcined LiAl-LDH derivative.

[0068] Sulphoaluminate cement-based materials include yellow and white materials. In the yellow material, there are 93g of clinker, 7g of sodium bentonite, 1.5g of naphthalene-based water reducer, and 0.25g of sodium gluconate. g. Weigh the roasted lithium-aluminum hydrotalcite derivatives prepared above according to 0.8% of the total amount of sulfoaluminate cement-based materials, and disperse them in externally mixed water by ultrasonication for 3 minutes at a power of 150W, and the roasted lithium-aluminum hydrotalci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com