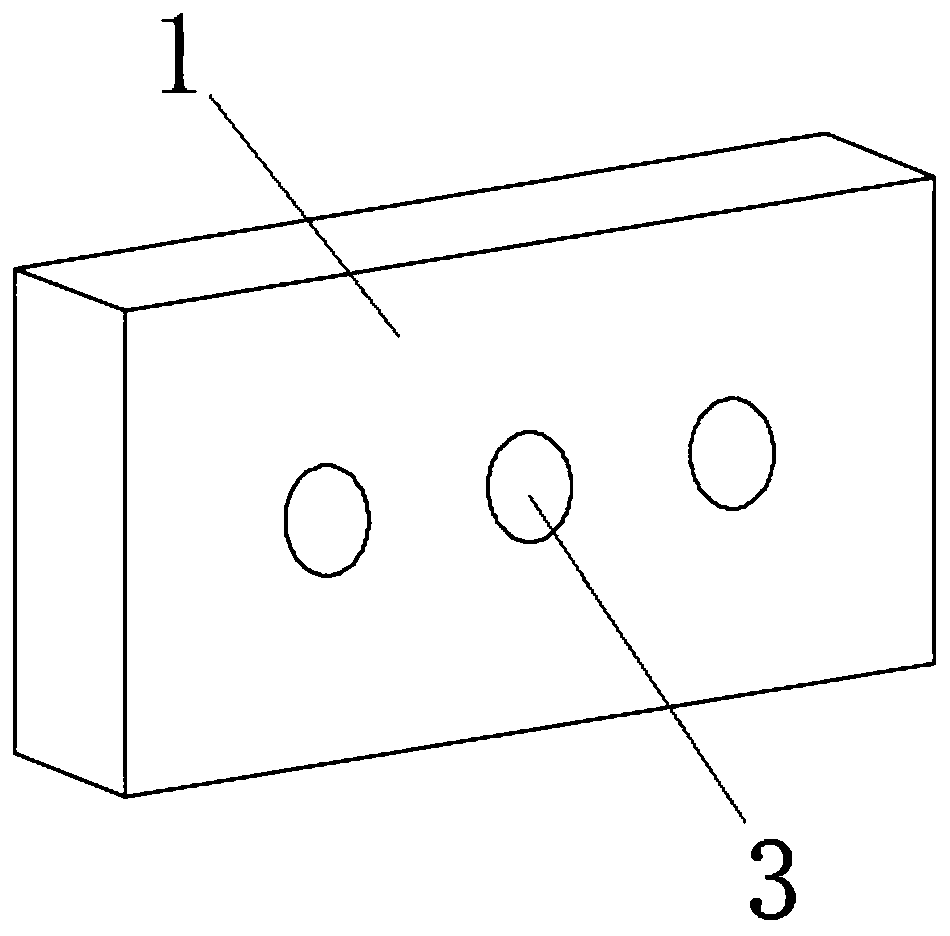

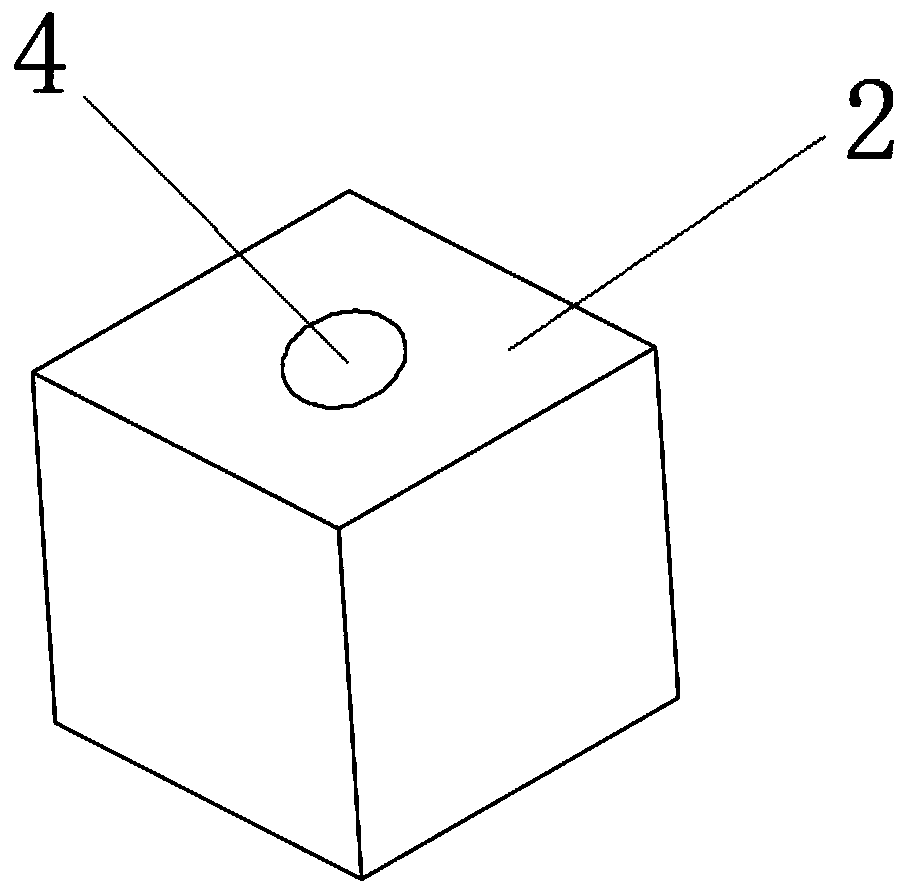

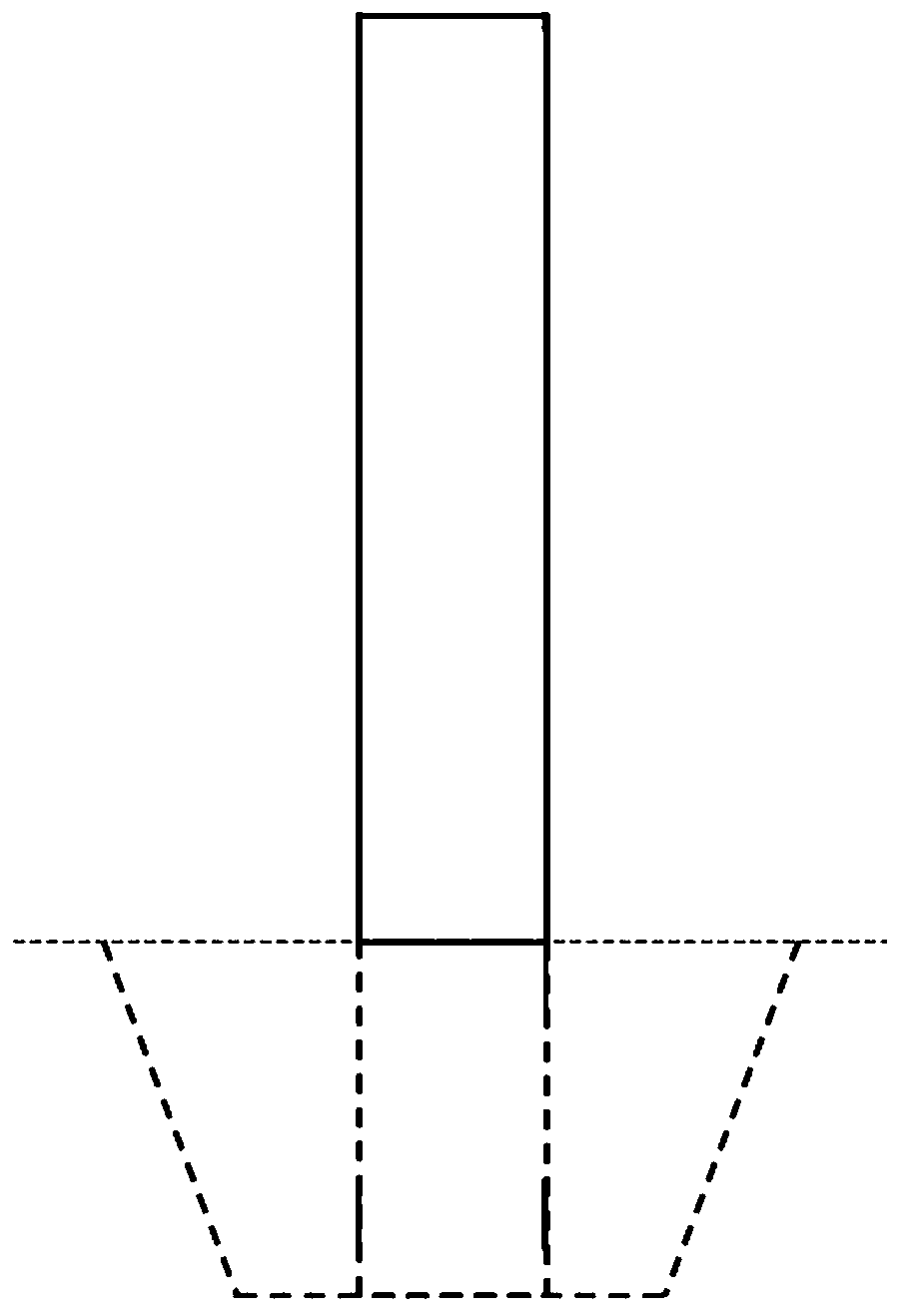

Brick capable of using salt-containing aeolian sand as raw materials and preparation method thereof

A technology for aeolian sand and bricks, applied in the field of bricks and their preparation, can solve the problems of the preparation of mechanical sand barriers, poor environmental adaptability, complicated preparation process, etc. The effect of good curing effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] ①At room temperature, prepare a portion of aeolian sand for use.

[0050] ②At room temperature, prepare a raw material of composite Portland cement P·C32.5 or geotechnical rock 5%-10%, water 8% and salt content 8%.

[0051] ③Under normal temperature, use vibration to make bricks to machine-made bricks.

[0052] ④ After the preparation of the sand-fixing sand barrier, it is maintained in a natural environment for 2 days.

[0053] ⑤ After curing, use a standard road strength tester to conduct an unconfined compressive strength test.

[0054] ⑥After the test, see Table 1 and Table 2 for the compressive strength of each proportion.

Embodiment 2

[0056] ①At room temperature, prepare a portion of aeolian sand for use.

[0057] ②At room temperature, prepare a raw material of composite Portland cement P·C32.5 or geotechnical rock 5%-10%, water 8% and salt content 8%.

[0058] ③Under normal temperature, use vibration to make bricks to machine-made bricks.

[0059] ④ After the preparation of the sand-fixing sand barrier, it is maintained in a natural environment for 2 days.

[0060] ⑤ After curing, carry out the dry-wet cycle test.

[0061] ⑥After 20 times of dry-wet cycle test, see Table 1 and Table 2 for the compressive strength of each proportion.

Embodiment 3

[0063] ①At room temperature, prepare a portion of aeolian sand for use.

[0064] ②At room temperature, prepare a raw material of composite Portland cement P·C32.5 or geotechnical rock 5%-10%, water 8% and salt content 8%.

[0065] ③Under normal temperature, use vibration to make bricks to machine-made bricks.

[0066] ④ After the preparation of the sand-fixing sand barrier, it is maintained in a natural environment for 2 days.

[0067] ⑤ After curing, conduct a freeze-thaw cycle test.

[0068] ⑥ After 20 freeze-thaw cycle tests, see Table 1 and Table 2 for the compressive strength of each mix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com