Full hydraulic intelligent shaft umbrella drill

A fully hydraulic and intelligent technology, applied in drilling equipment, earthwork drilling, support devices, etc., can solve the problems of full working face, dust and noise without improvement, low drilling efficiency, etc., and achieve flexible and intelligent operation The effect of high level and fast switching between translation and anti-translation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

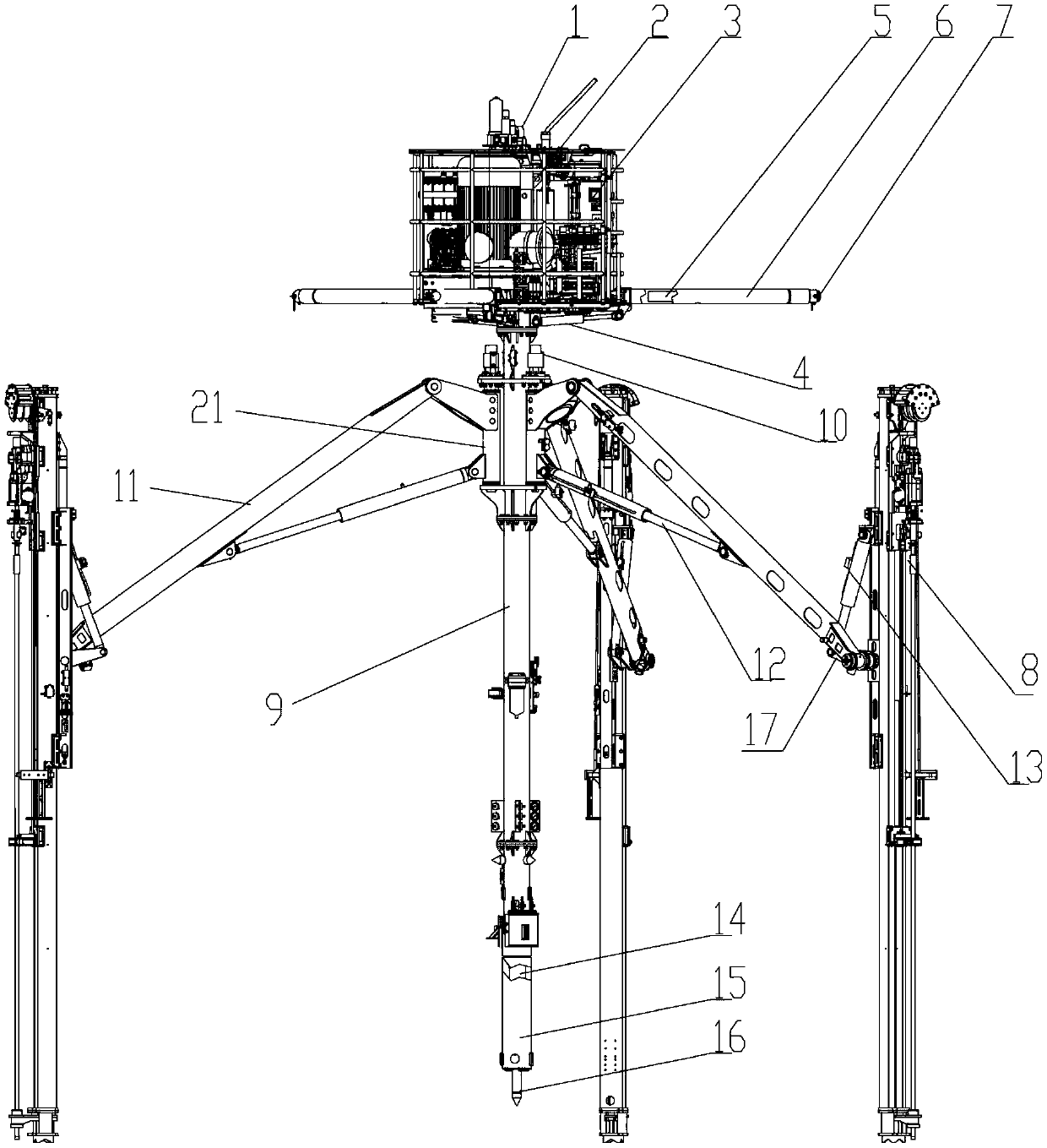

[0029] Embodiment: Referring to the accompanying drawings, the fully hydraulic intelligent shaft parachute drill of the present embodiment includes:

[0030] The retractable support column 9 is provided with a work platform on the top of the support column 9, and side supports 6 are respectively hinged on both sides of the work platform; two turning cylinders 4 are arranged, one end of the turning cylinder 4 is hinged with the side support 6, and the other end Hinged on the support column 9; each side support 4 is coaxially provided with a telescopic oil cylinder 5, and a positioner 7 is connected to the end of the piston rod of the telescopic oil cylinder 5, and the positioner 7 can extend out of the side support 6;

[0031] A sleeve 21 is sleeved on the outside of the support column 9, and the sleeve 21 is driven by the rotary cylinder 10 to rotate around the axis of the support column 9;

[0032] The umbrella drill also has a translation system, which includes: a carriage 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com