Drying system for preparing composite aerogel self-insulation template

A technology of composite airgel and drying system, which is applied in the field of drying system for preparing composite airgel self-insulation formwork, which can solve the problems of low drying efficiency, poor drying effect, and inability to turn over the heat insulation felt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

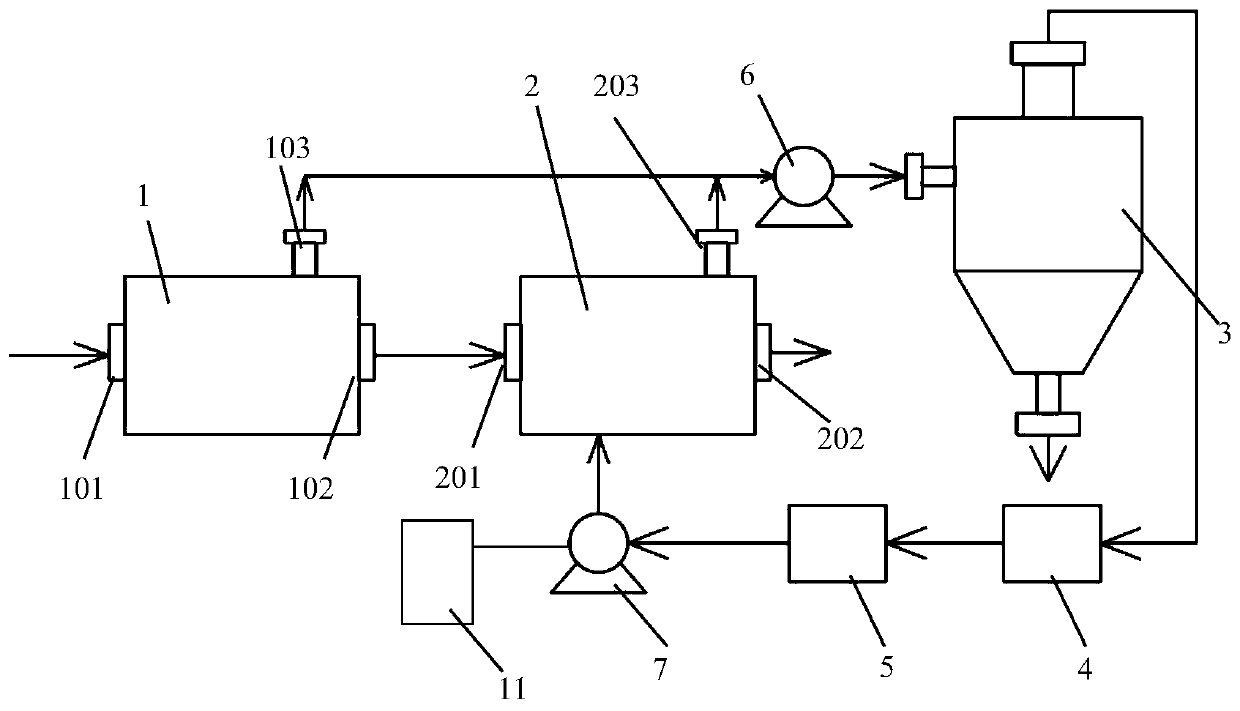

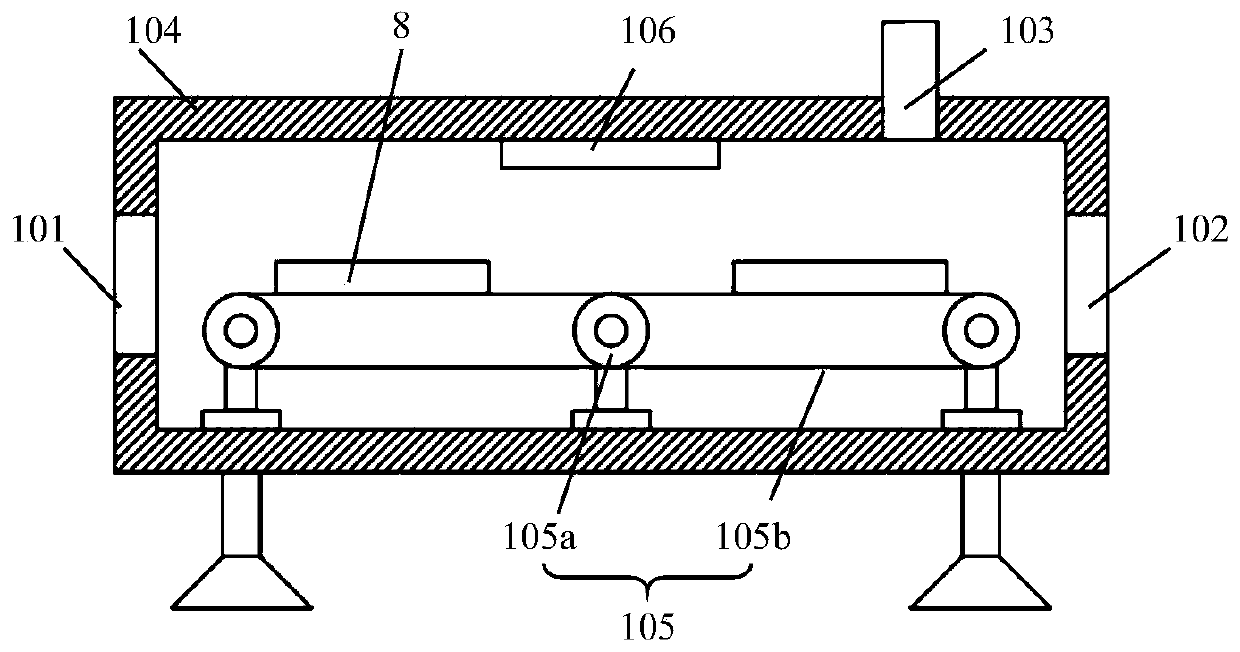

[0039] Such as figure 1 As shown, the present invention provides a drying system, which includes at least a first-stage dryer 1 and a second-stage dryer 2. The first-stage dryer 1 is used to perform the first-stage drying treatment on the composite aerogel self-insulating template 8. The second-stage dryer 2 is used to perform a second-stage drying treatment on the composite aerogel self-insulating template 8. Specifically, the first-stage dryer 1 has at least a first inlet 101 and a first outlet 102. The second-stage dryer 2 has at least a second inlet 201 and a second outlet 202. The composite aerogel self-insulation template 8 can enter the first-stage dryer 1 from the first inlet 101, and is discharged from the first outlet 102 after the first-stage drying process is completed. The composite aerogel self-insulating template 8 after the first-stage drying treatment can enter the second-stage dryer 2 through the second inlet 201 for the second-stage drying treatment. The c...

Embodiment 2

[0045] This embodiment is a further improvement of Embodiment 1, and the repeated content will not be repeated.

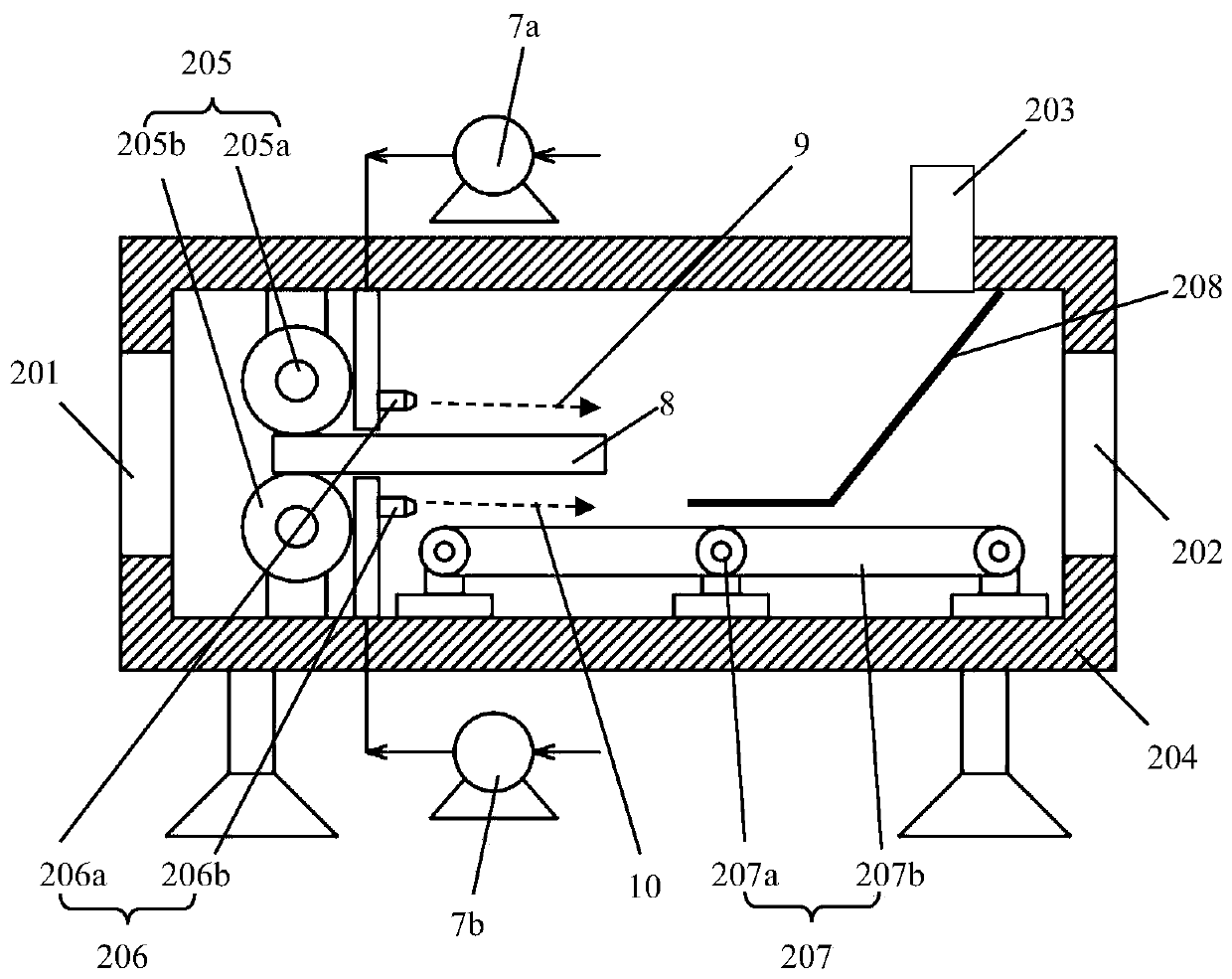

[0046] Such as image 3 As shown, the second-stage dryer 2 at least includes a housing 204, a clamping mechanism 205, a blowing mechanism 206, and a first conveying mechanism 207. The second inlet 201, the second outlet 202 and the second air outlet 203 are all provided on the housing 204. The clamping mechanism 205 is used to clamp the composite aerogel self-insulation template, so that the composite aerogel self-insulation template can be partially suspended. Specifically, the clamping mechanism 205 can clamp the first end of the composite aerogel self-insulating template, thereby making the second end of the composite aerogel suspended. For example, such as image 3 As shown, the clamping mechanism 205 can clamp the left end of the composite aerogel self-insulating template, thereby making the right end of the composite aerogel self-insulating template in a susp...

Embodiment 3

[0052] This embodiment is a further improvement of the foregoing embodiment, and the repeated content will not be repeated.

[0053] Preferably, the second-stage dryer 2 is configured to form a first air flow 9 and a second air flow 10 with different flow rates and alternate flow rates on both sides of the composite aerogel self-insulating template 8 to form alternate pressures. Therefore, the composite aerogel self-insulating template 8 can realize the first-stage air-drying treatment in a manner of presenting a swing state based on the pressure difference. Specifically, the drying system further includes a control box 11. Both the first blower 7a and the second blower 7b are connected to the control box 11, so that the control box 11 can control the first blower 7a and the second blower 7b to realize the first-stage air drying process. The control box 11 is configured to control the second-stage dryer to perform the first-stage air drying treatment in the following manner:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com