Sintering mixed water adding control method based on dual-model collaborative prediction

A control method and dual-model technology, applied in neural learning methods, biological neural network models, character and pattern recognition, etc., can solve the problem of low predictive control efficiency, the moisture content of the mixture cannot meet the process requirements, and the feedforward prediction accuracy is not accurate. It can improve the sintering production efficiency, stabilize the moisture content and improve the granulation index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

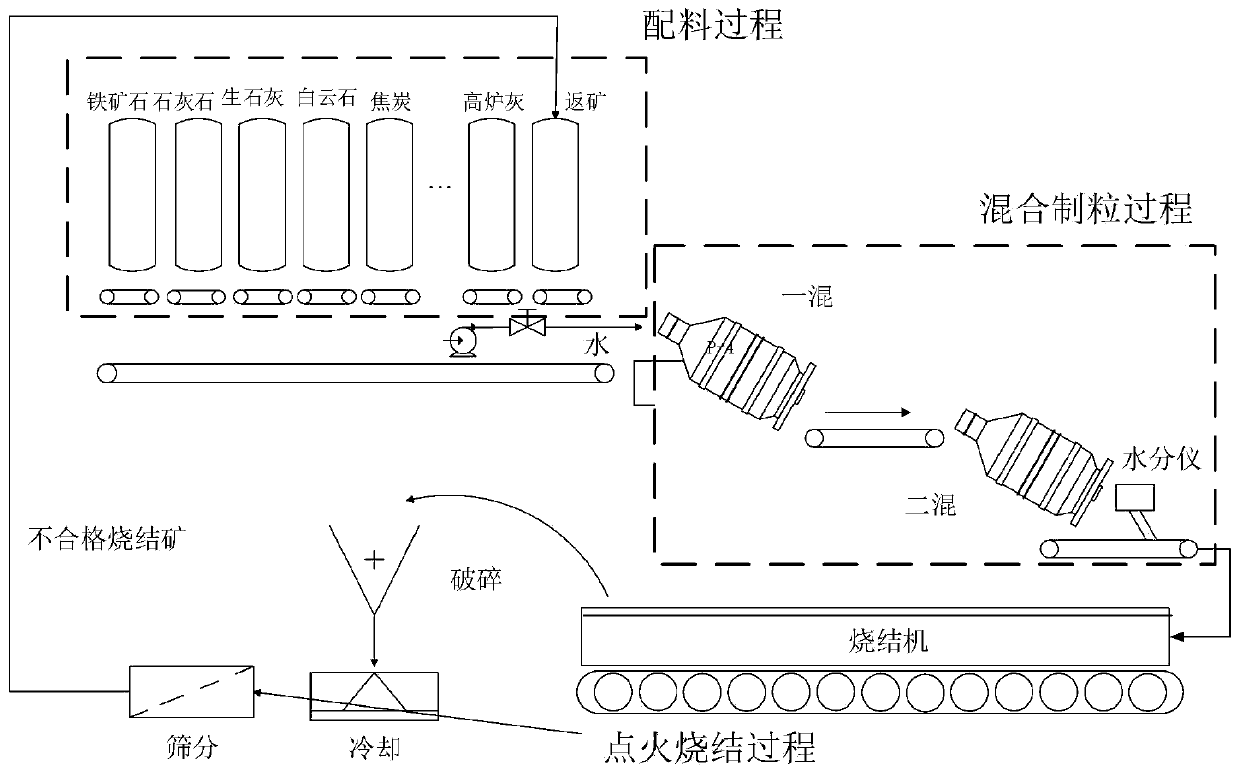

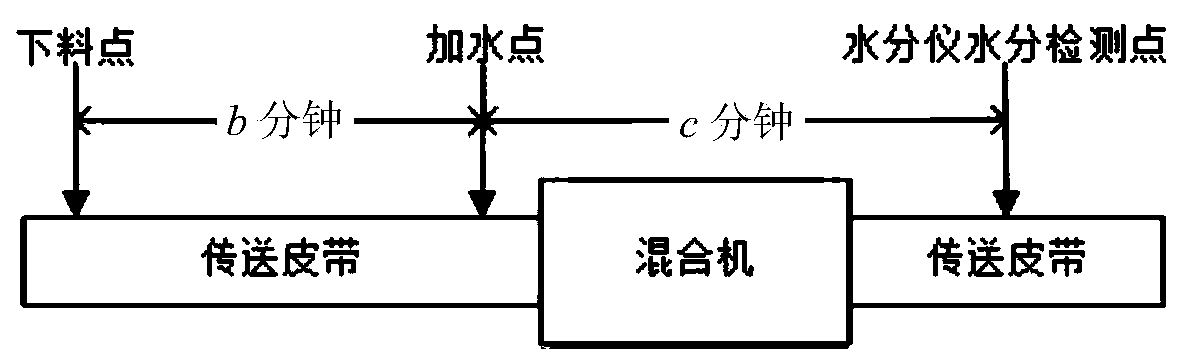

[0040] The invention controls the addition of water for sintering mixing based on double-model cooperative prediction. In this embodiment, the sintering process such as figure 1 As shown, the whole sintering process is to make various raw materials, including powdery materials such as iron ore powder, flux, fuel, etc. Mixing and granulation forms the mixture for sintering, and then the sintering ore can be formed through the distribution of the distribution machine and the sintering of the sintering machine. Among them, a moisture meter is installed at the outlet of the mixing and granulation process to detect the moisture content of the mixture. Such as figure 2 As shown, there is a time delay during sintering and water mixing: from figure 2 It can be seen that, taking the water addition point as the reference point, there is a delay of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com