Marine nuclear power platform reactor pressure vessel support skirt

A technology for pressure vessels and reactors, applied in the fields of reactors, nuclear engineering, nuclear power generation, etc., can solve the problems of inability to clear the root of the bottom weld, leakage, and difficult non-destructive testing of the top weld, so as to achieve easy heat transfer, reduce safety risks, Solving the effect of radiation deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

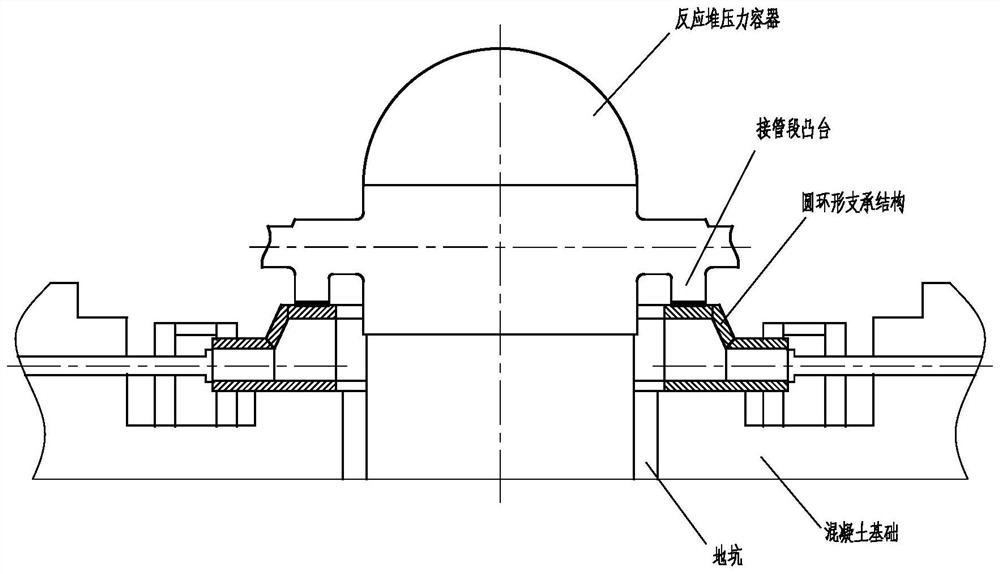

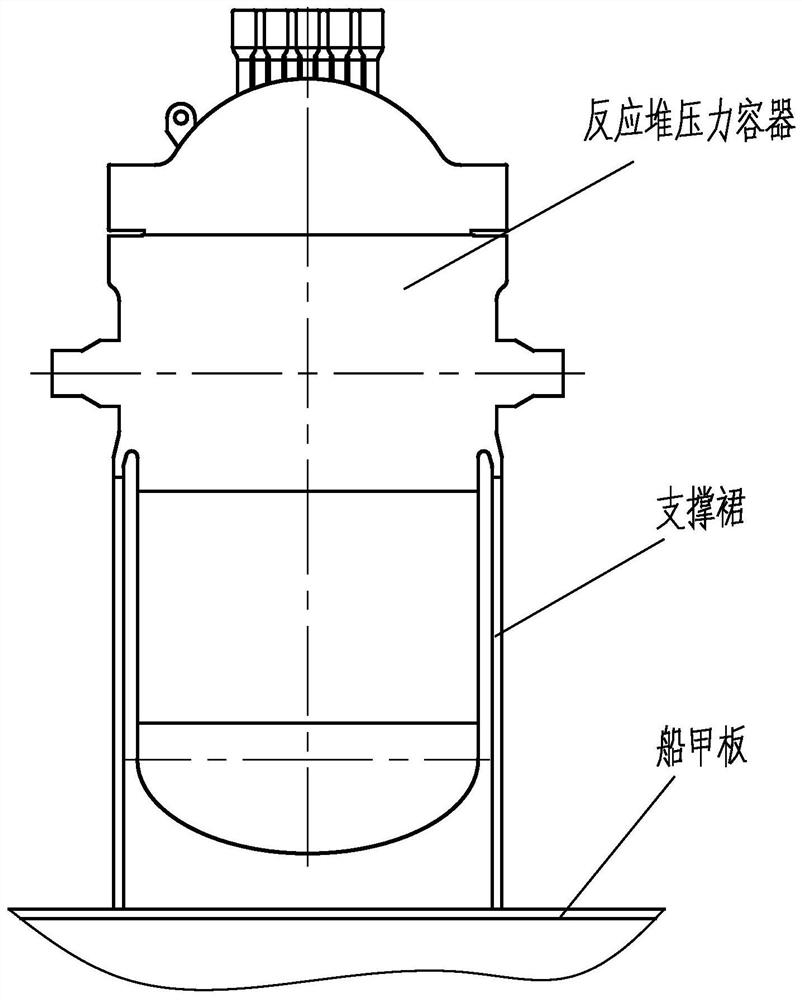

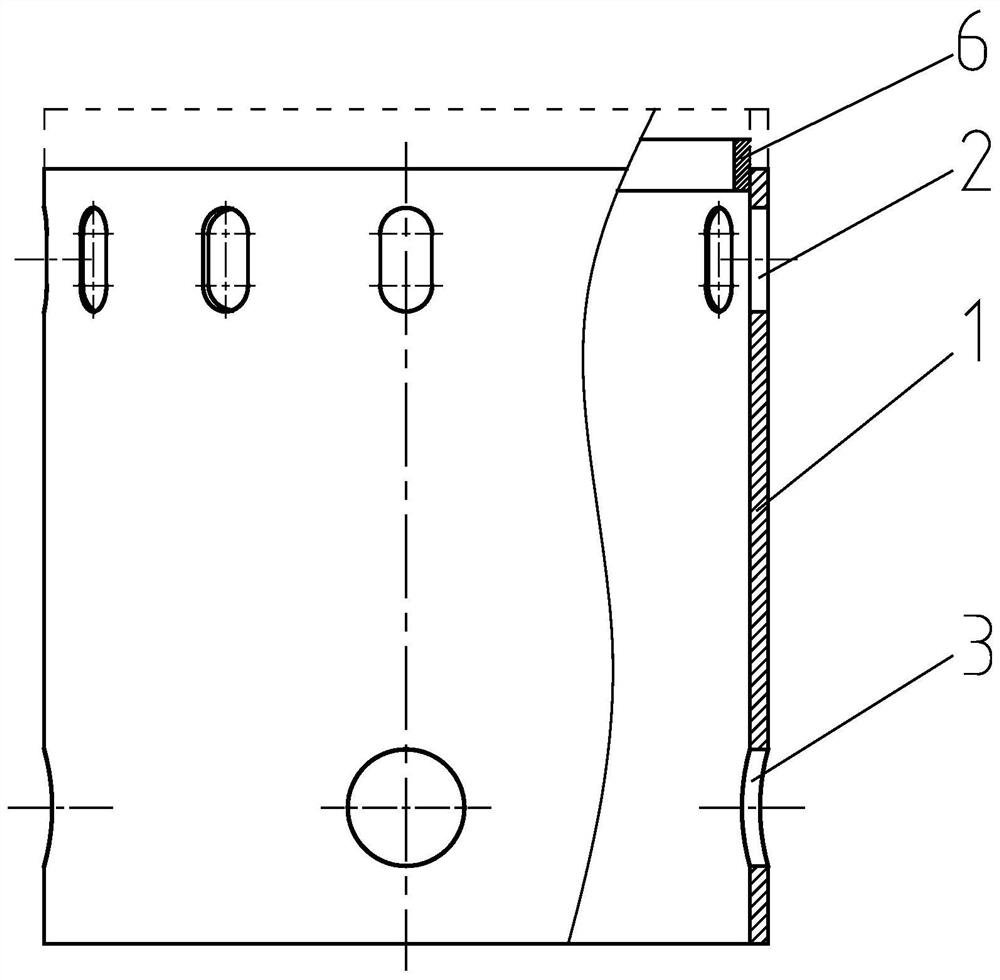

[0024] The reactor pressure vessel support skirt of the marine nuclear power platform as shown in the figure includes a cylinder body 1, which is a thin-walled cylindrical structure, and the upper and lower end surfaces of the cylinder body 1 are welded to the reactor pressure vessel 4 and the containment bottom plate 5 respectively. The upper part of the cylinder body 1 is provided with more than three waist-shaped exhaust holes 2, the long and short axes of the waist-shaped exhaust holes 2 are located in the vertical and horizontal directions respectively, and each waist-shaped exhaust hole 2 is located at the same level , the distance between the center line of the waist circular exhaust hole 2 and the top of the cylinder body 1 is 350mm-450mm, and the bottom of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com