Adjustable capacitive coupling structure

A capacitive coupling and adjustable technology, which is applied to circuits, electrical components, waveguide devices, etc., can solve problems such as increased labor costs, extended debugging time, and size deviation of capacitive coupling structures, so as to improve the adjustment range and reduce the difficulty of debugging , Reduce the effect of debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

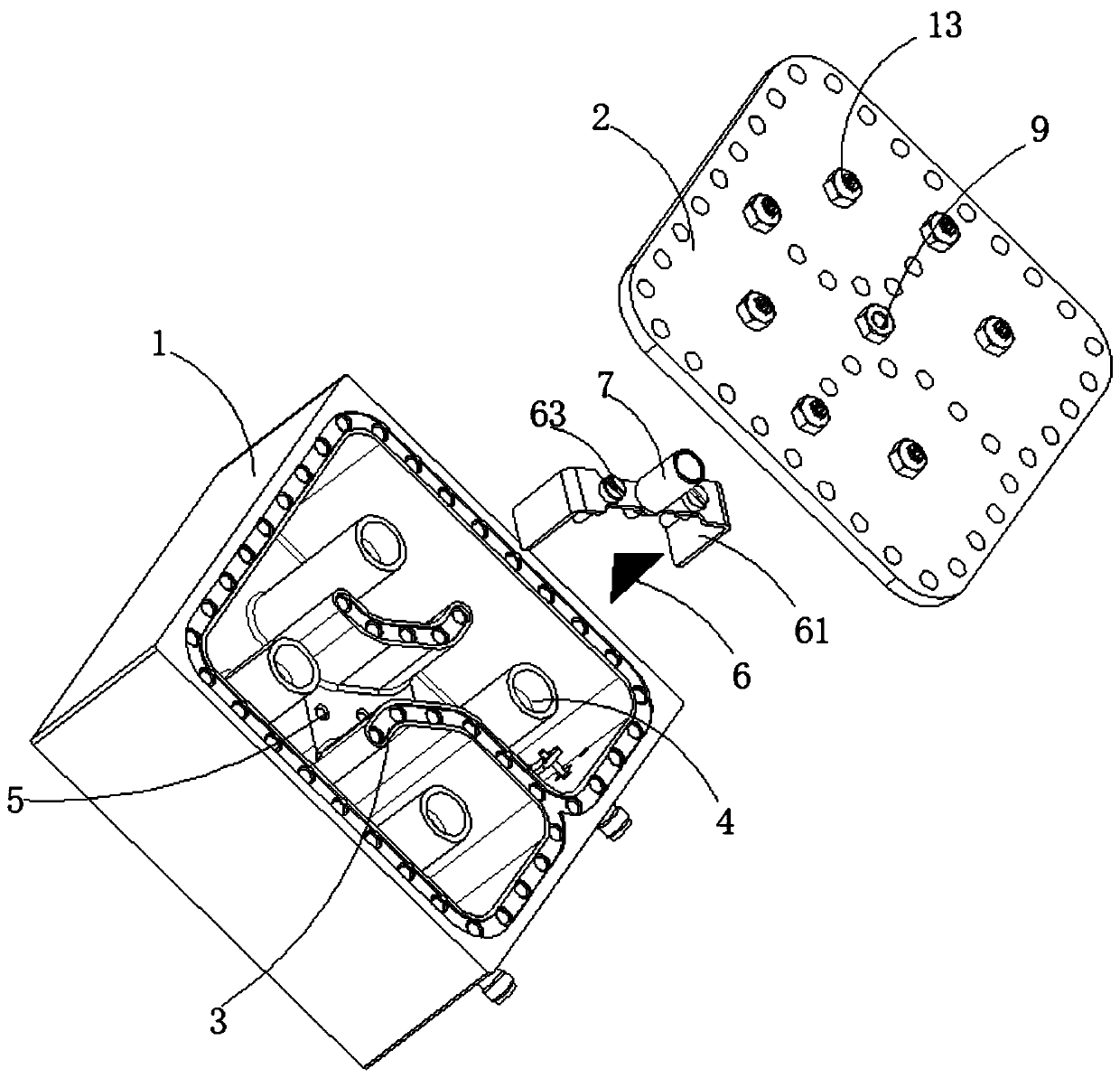

[0035] Such as Figure 1 to Figure 5 The adjustable capacitive coupling structure shown, including

[0036] chamber 1;

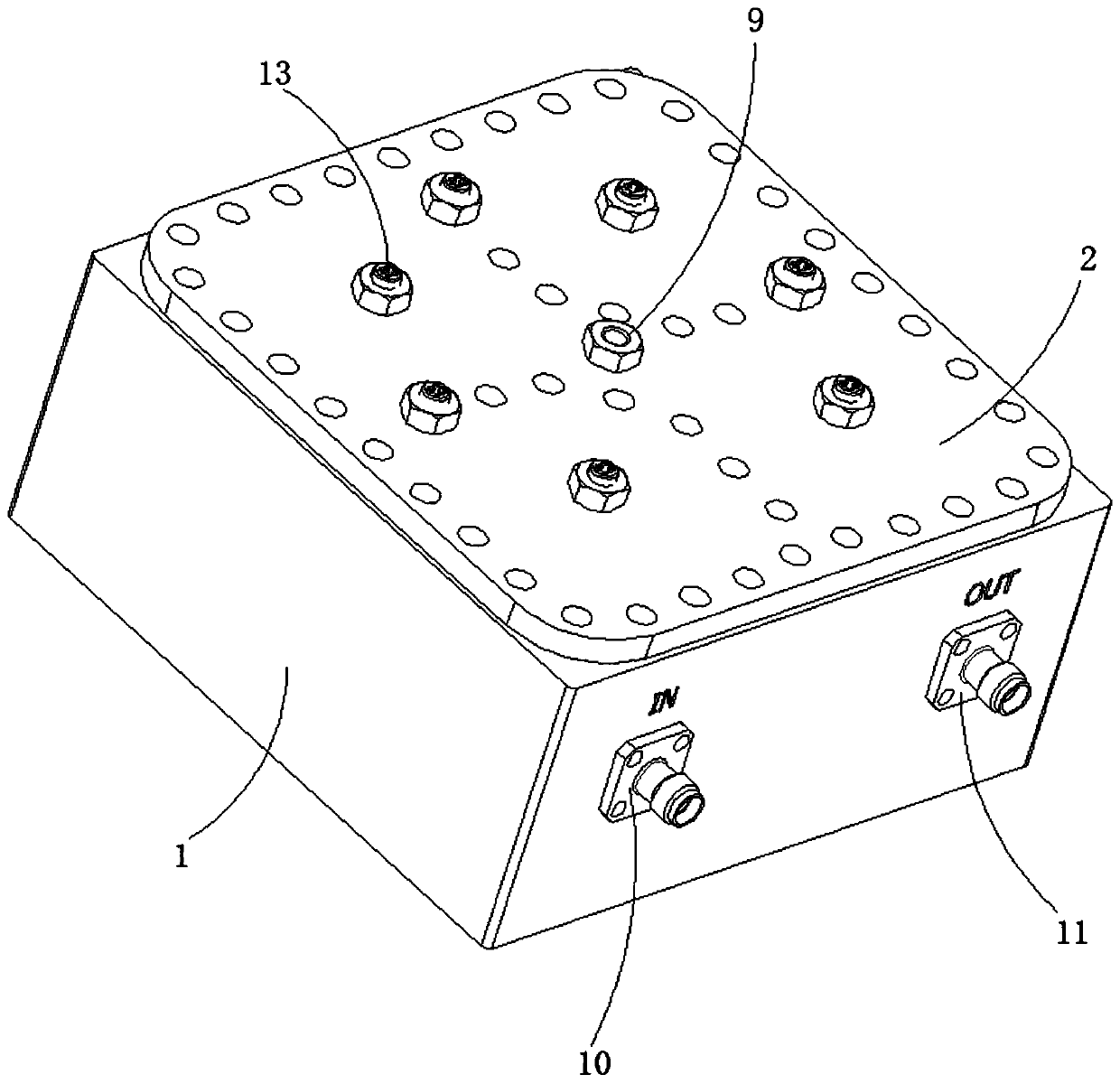

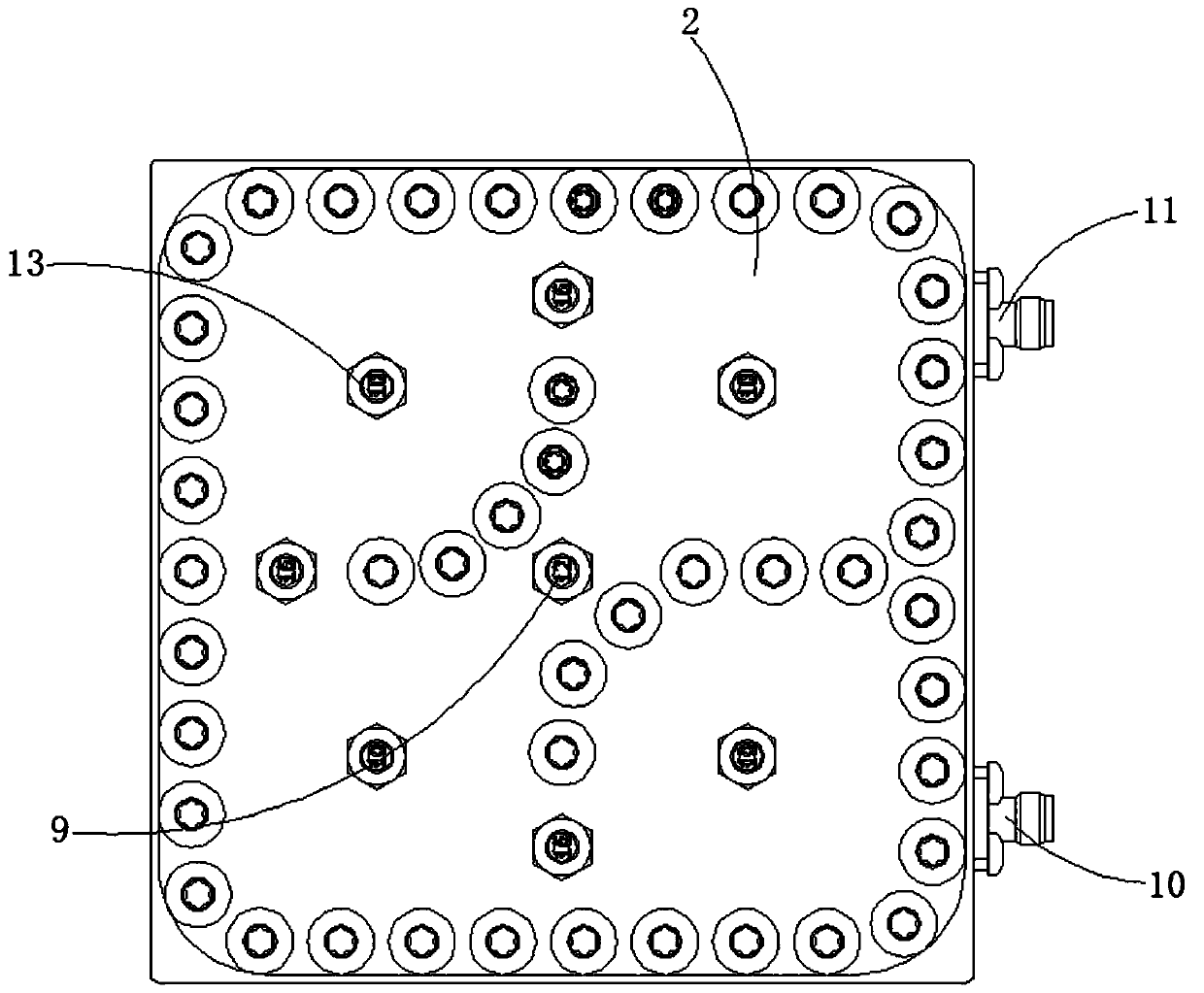

[0037] The cover plate 2 is detachably connected to the top of the cavity 1;

[0038] Also includes

[0039] The partition wall 3 is arranged in the cavity 1, and the cavity 1 is divided into a plurality of resonant cavities by the partition wall 3;

[0040] The resonant rod 4 is arranged in the resonant cavity and fixedly connected to the bottom inner wall of the cavity 1;

[0041] The slot 5 is opened on the partition wall 3

[0042] Capacitive coupling assembly 6: including capacitive coupling copper sheet 61, capacitive support 62 and dielectric screw 63, the dielectric screw 63 is connected in the slot 5, capacitive coupling copper 61 and capacitive support 62 are equipped with Cooperating slotting, the capacitive coupling copper sheet 61 and the capacitive support member 62 are connected to the top of the partition wall 3 through the dielectric sc...

Embodiment 2

[0052] Such as Figure 1-6 The adjustable capacitive coupling structure shown, including

[0053] chamber 1;

[0054] The cover plate 2 is detachably connected to the top of the cavity 1;

[0055] Also includes

[0056] The partition wall 3 is arranged in the cavity 1, and the cavity 1 is divided into a plurality of resonant cavities by the partition wall 3;

[0057] The resonant rod 4 is arranged in the resonant cavity and fixedly connected to the bottom inner wall of the cavity 1;

[0058] The slotted hole 5 is opened on the partition wall 3

[0059] Capacitive coupling assembly 6: including capacitive coupling copper sheet 61, capacitive support 62 and dielectric screw 63, the dielectric screw 63 is connected in the slot 5, capacitive coupling copper 61 and capacitive support 62 are equipped with Cooperating slotting, the capacitive coupling copper sheet 61 and the capacitive support member 62 are connected to the top of the partition wall 3 through the dielectric scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com