Wire lossless hot stripping device and application method thereof

A wire and spindle technology, used in cable installation devices, cable installation, equipment for dismantling/armored cables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

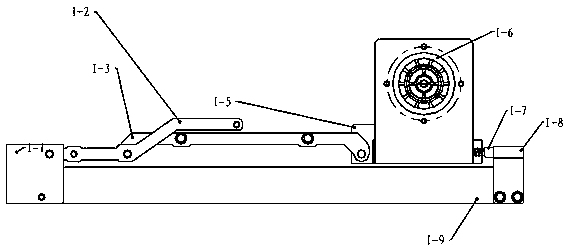

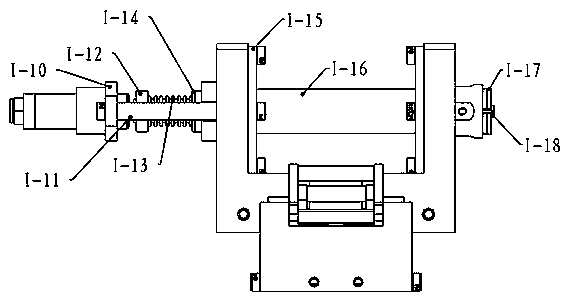

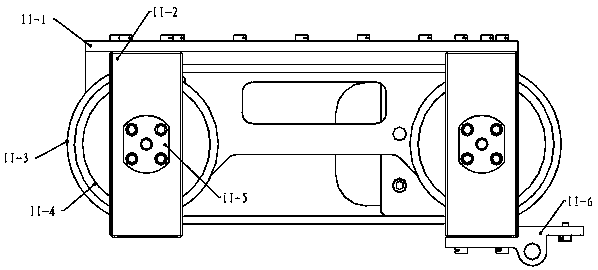

[0035] A wire non-destructive thermal stripping device and a use method thereof are suitable for non-destructive stripping of extra-fine wires. The device is mainly composed of four parts: ①Spindle slider device, which is composed of the main shaft, crank slider mechanism, elastic collet and other parts, is responsible for clamping and rotating the wire, and participating in power connection and disconnection; ②Belt wheel drive device , composed of motor, driving wheel, driven wheel, belt and corresponding bracket, responsible for providing power for the rotation of the main shaft; ③Sliding table tool holder device, consisting of X-direction sliding table, Y-direction sliding table, thermal resistance blade, tool holder, magnetic restraint The device is responsible for the scalding of the wire insulation; ④The base part is composed of bases, support rods, hinge brackets and other parts, and is responsible for connecting the spindle slider device, pulley drive device, and slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com