Device and method for stripping coating layer of polyimide-coated copper wire

A technology of polyimide and coating layer, which is applied in the field of surface treatment of polymer materials, can solve problems affecting welding quality, copper core surface oxidation, high heating temperature, etc., achieve rapid stripping, reduce copper core oxidation, and reduce copper The effect of core temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

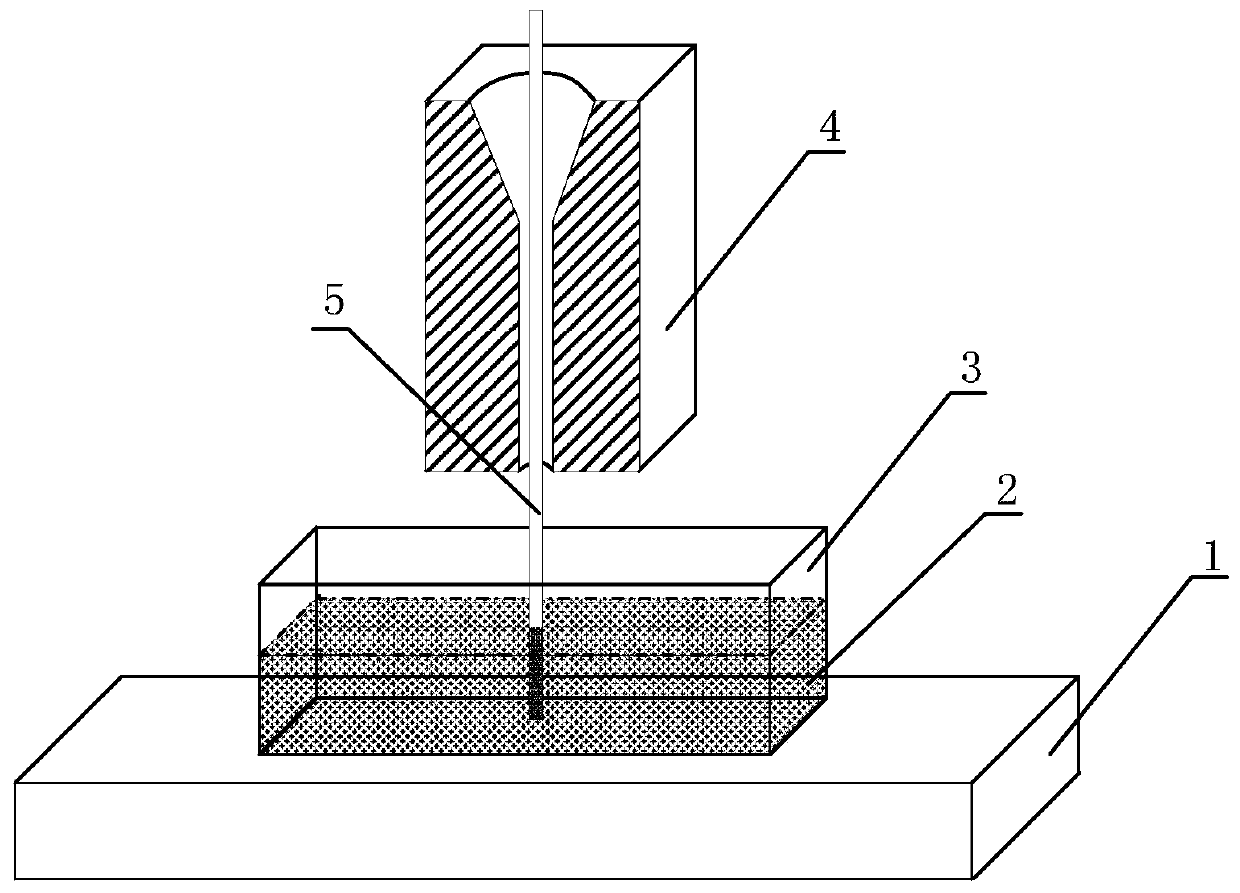

Method used

Image

Examples

Embodiment 1

[0056] Enameled wire diameter 0.15mm, coating thickness 0.01mm. Pour the paint stripping powder into an iron crucible, set the temperature at 200°C, heat until the paint stripping powder is completely melted, and keep it warm for 5 minutes. Pass the enameled wire through the collimator, insert it vertically into the molten liquid, the length of immersion in the liquid is 5mm, let it stand for 8s, and take it out. Rinse in deionized water for 5 seconds, take it out, and blow dry.

[0057] The paint remover 2 includes the following components in mass percent: 13% sodium hydroxide, 42% potassium hydroxide, 20% sodium acetate, and 25% sodium cellulose.

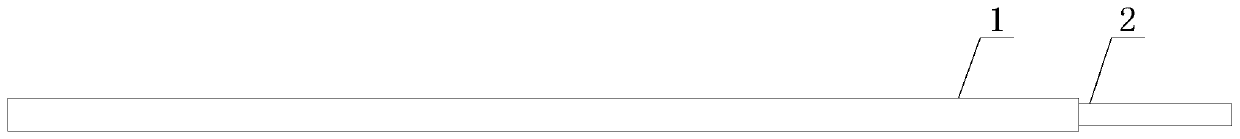

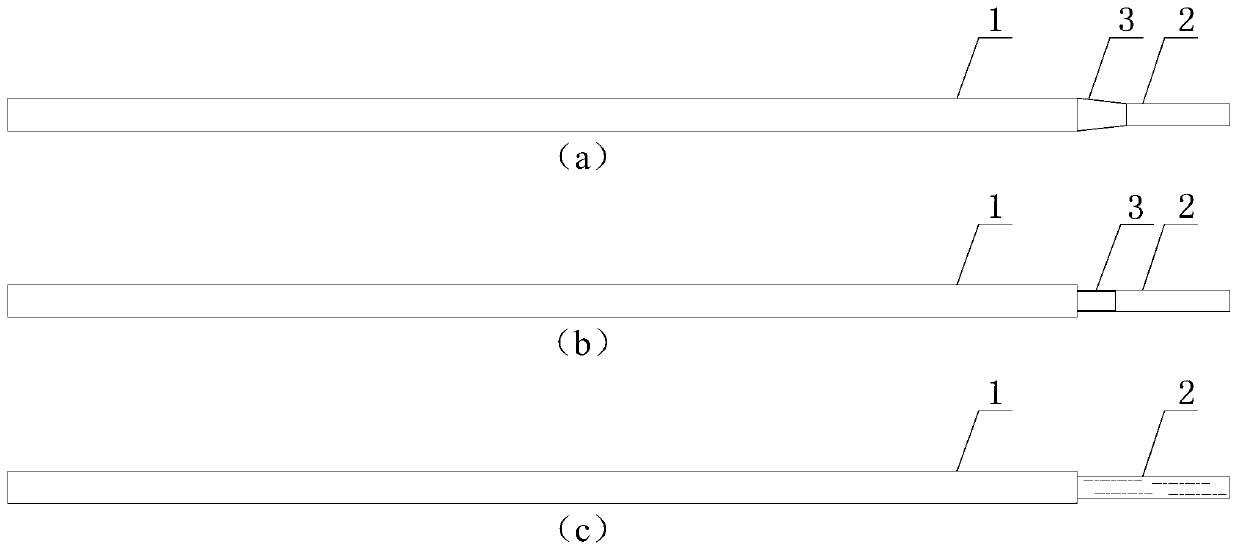

[0058] The surface of the copper core of the enameled wire after removing the coating layer in the embodiment of the present invention is bright and free of oxidation, the coating is completely removed without residue, the boundary is neat and there is no transition, the coating stripping length is 5 mm, and the schematic diagram...

Embodiment 2

[0060] The diameter of the enameled wire is 0.2mm, and the thickness of the coating is 0.015mm. Pour the paint stripping powder into an iron crucible, set the temperature at 210°C, heat until the paint stripping powder is completely melted, and keep it warm for 5 minutes. Pass the enameled wire through the collimator, insert it vertically into the molten liquid, and immerse it in the liquid to a length of 15 mm, let it stand for 10 seconds, and then take it out. Rinse in deionized water for 5 seconds, take it out, and blow dry.

[0061] The paint remover 2 includes the following components in mass percentage: 11% sodium hydroxide, 44% potassium hydroxide, 18% sodium acetate, and 27% sodium cellulose.

[0062] The surface of the copper core of the enameled wire after removing the coating layer in the embodiment of the present invention is bright and free of oxidation, the coating is completely removed without residue, the boundary is neat and there is no transition, and the coa...

Embodiment 3

[0064] The wire diameter of the enameled wire is 0.3mm, and the thickness of the coating is 0.02mm. Pour the paint stripping powder into an iron crucible, set the temperature at 210°C, heat until the paint stripping powder is completely melted, and keep it warm for 5 minutes. Pass the enameled wire through the collimator, insert it vertically into the molten liquid, and immerse it in the liquid for a length of 10 mm, let it stand for 12 seconds, and then take it out. Rinse in deionized water for 5 seconds, take it out, and blow dry.

[0065] The paint remover 2 includes the following components in mass percentage: 114% sodium hydroxide, 45% potassium hydroxide, 21% sodium acetate, and 20% sodium cellulose.

[0066] The surface of the copper core of the enameled wire after removing the coating layer in the embodiment of the present invention is bright and free from oxidation, the coating is completely removed without residue, the boundary is neat and there is no transition, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com