Preparation method of disposable laminated regenerated cellulose membrane straws

A technology of regenerated cellulose film and regenerated fiber, applied in the direction of table utensils, home utensils, table utensils, etc., can solve problems such as toxic substances and harm to health, and achieve the effect of improving waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

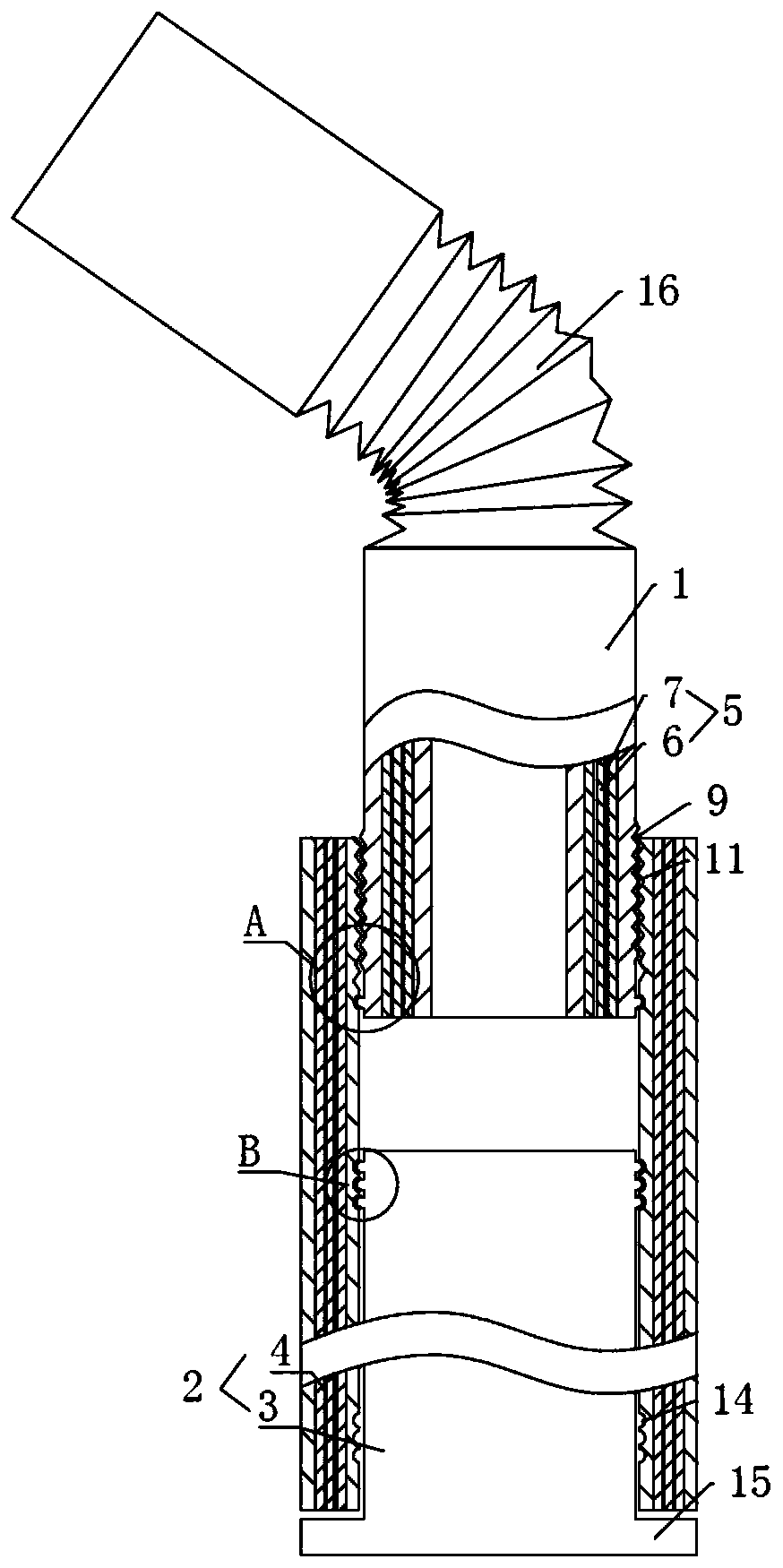

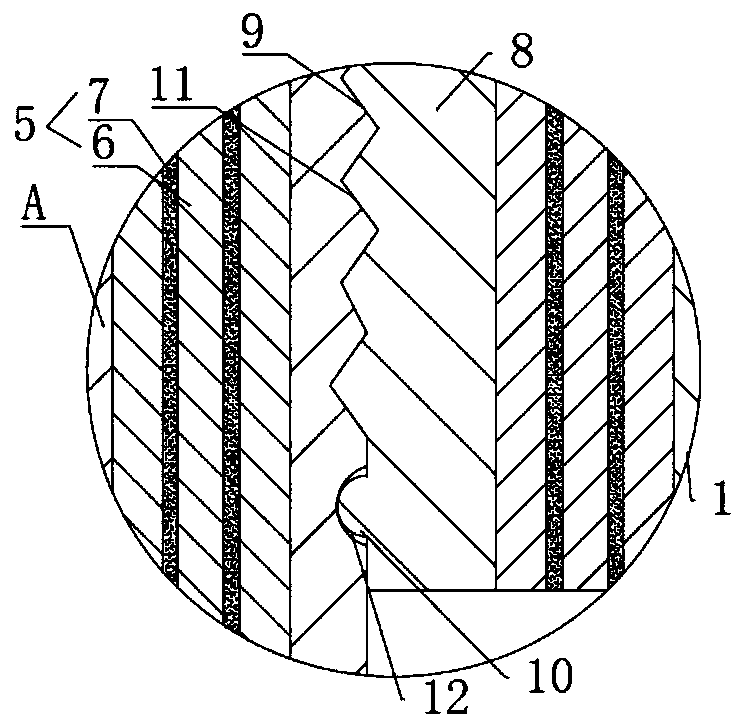

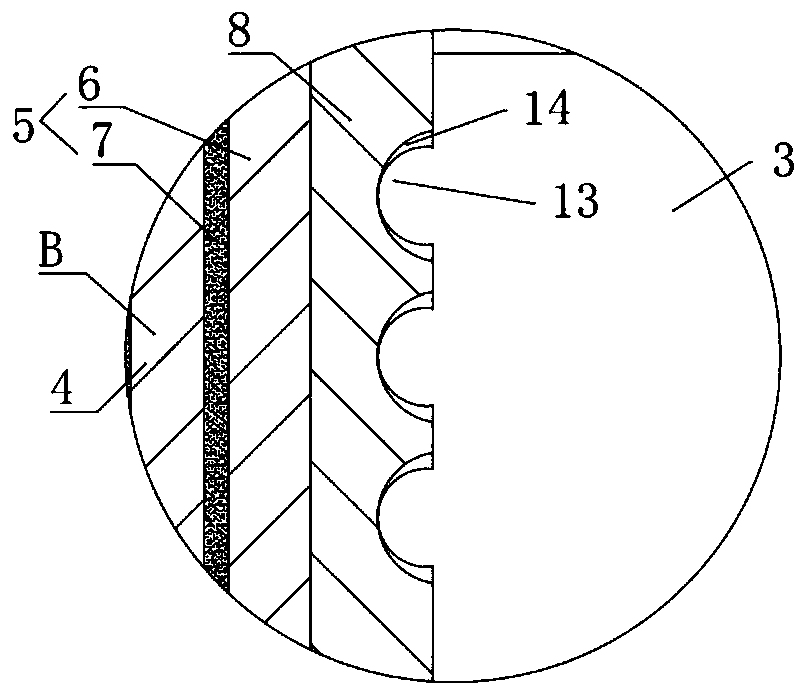

Image

Examples

Embodiment 1

[0026] A manufacturing method of a coated regenerated cellulose film straw in this embodiment, first cut the regenerated cellulose film into rolls with a slitting machine to make it into a suitable size; then glue the regenerated cellulose film according to the thickness of the straw , multi-layer compounding, coiling, cutting, and making into tubes of different specifications; and then coating the composite film tubes, and adding a layer of film to the inner and outer layers of the tubes to make them waterproof, oil-proof, and high-temperature resistant. ; Then dry and shape the coated straws and adjust the humidity to obtain disposable coated regenerated cellulose film straws of different specifications. Taking the production of coated regenerated cellulose film straws with a length of 200mm, a thickness of 0.2mm, and a diameter of 6mm as an example, the specific operation steps are as follows:

[0027] (1) Cutting regenerated fiber film: According to the thickness requireme...

Embodiment 2

[0036] A manufacturing method of a coated regenerated cellulose film straw in this embodiment, first cut the regenerated cellulose film into rolls with a slitting machine to make it into a suitable size; then glue the regenerated cellulose film according to the thickness of the straw , multi-layer compounding, coiling, cutting, and making into tubes of different specifications; and then coating the composite film tubes, and adding a layer of film to the inner and outer layers of the tubes to make them waterproof, oil-proof, and high-temperature resistant. ; Then dry and shape the coated straws and adjust the humidity to obtain disposable coated regenerated cellulose film straws of different specifications. Taking the production of coated regenerated cellulose film straws with a length of 250mm, a thickness of 0.3mm and a diameter of 6.5mm as an example, the specific operation steps are as follows:

[0037] (1) Cutting regenerated fiber film: According to the thickness requirem...

Embodiment 3

[0046] A manufacturing method of a coated regenerated cellulose film straw in this embodiment, first cut the regenerated cellulose film into rolls with a slitting machine to make it into a suitable size; then glue the regenerated cellulose film according to the thickness of the straw , multi-layer compounding, coiling, cutting, and making into tubes of different specifications; and then coating the composite film tubes, and adding a layer of film to the inner and outer layers of the tubes to make them waterproof, oil-proof, and high-temperature resistant. ; Then dry and shape the coated straws and adjust the humidity to obtain disposable coated regenerated cellulose film straws of different specifications. Taking the production of coated regenerated cellulose film straws with a length of 280mm, a thickness of 0.5mm, and a diameter of 7mm as an example, the specific operation steps are as follows:

[0047](1) Cutting regenerated fiber film: According to the thickness requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com