Integrated dedusting, desulfurization and denitrification device for ship exhaust gases

A technology for desulfurization, denitrification, and ship exhaust, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as unfavorable emissions, general mixing rates, and cumbersome treatment methods, and achieve the effect of saving energy and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

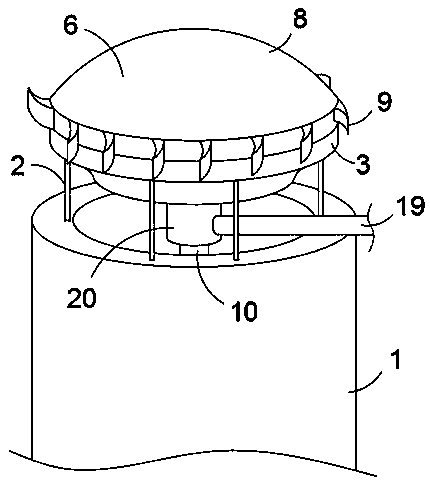

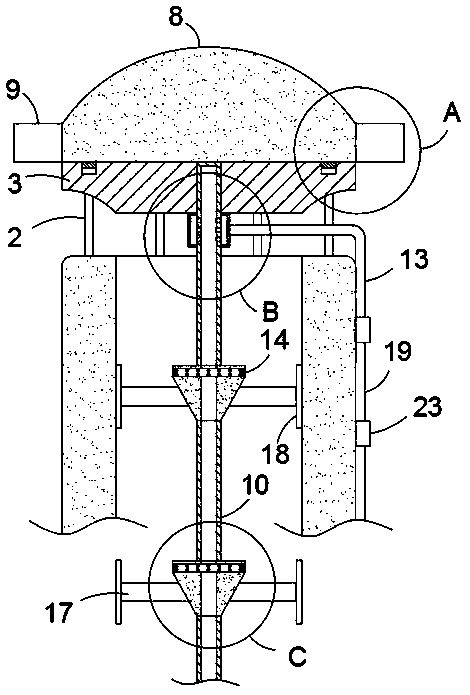

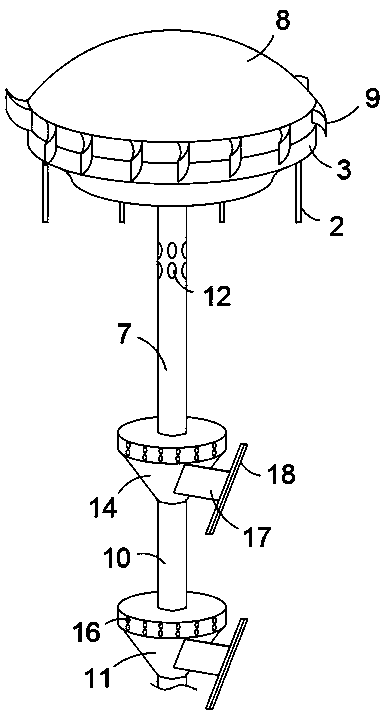

[0028] Such as Figure 1-6 As shown, an integrated dust removal, desulfurization and denitrification device for ship exhaust includes a hull exhaust pipe 1, which is a part of the hull and is used to discharge engine exhaust. There are multiple metal support columns 2 vertically and fixedly connected to the top surface of the platform. The upper ends of the multiple support columns 2 are fixedly connected to the same support block 3 for building a platform. The bottom side of the support block 3 is an arc that floats outward. On the surface, the outer arc surface can guide the high-temperature gas ejected from the exhaust pipe of the hull to the fan blade 9 to further improve the effect and speed of its rotation. The support block 3 is cylindrical, and the upper end of the support block 3 is coaxially provided with The chute 4 is provided with a plurality of matching slide blocks 5 in the chute 4 .

[0029] The upper end of support block 3 is provided with turning mechanism 6...

Embodiment 2

[0035] refer to Figure 7-8 , the difference between this embodiment and embodiment 1 is:

[0036] A plurality of feeding pipes 10 are coaxially slidingly sleeved with a closing cover 24, which is in the shape of a downward bung, and is used to close a plurality of spray holes 16 when the machine is shut down. Directly above the connection block 14, a floating plate 25 is coaxially sleeved on the feeding pipe 10. The floating plate 25 is a high-temperature-resistant lightweight material. A limiting plate 26 for limiting the closure cover 24 is fixedly connected coaxially.

[0037] Compared with Embodiment 1, the advantage of this embodiment is that when the ship is not sailing, since its overall rotating mechanism is in the form of no active power, a small amount of liquid may drop into the hull exhaust pipe 1, which may cause adverse effects, and at the same time There will also be impurities entering the spray hole 16 and causing it to be blocked, so the closing cover 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com