A method for segmental heating and spinning of sheet metal

A spinning forming and segmental heating technology, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven billet temperature, product scrapping, and low flame heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

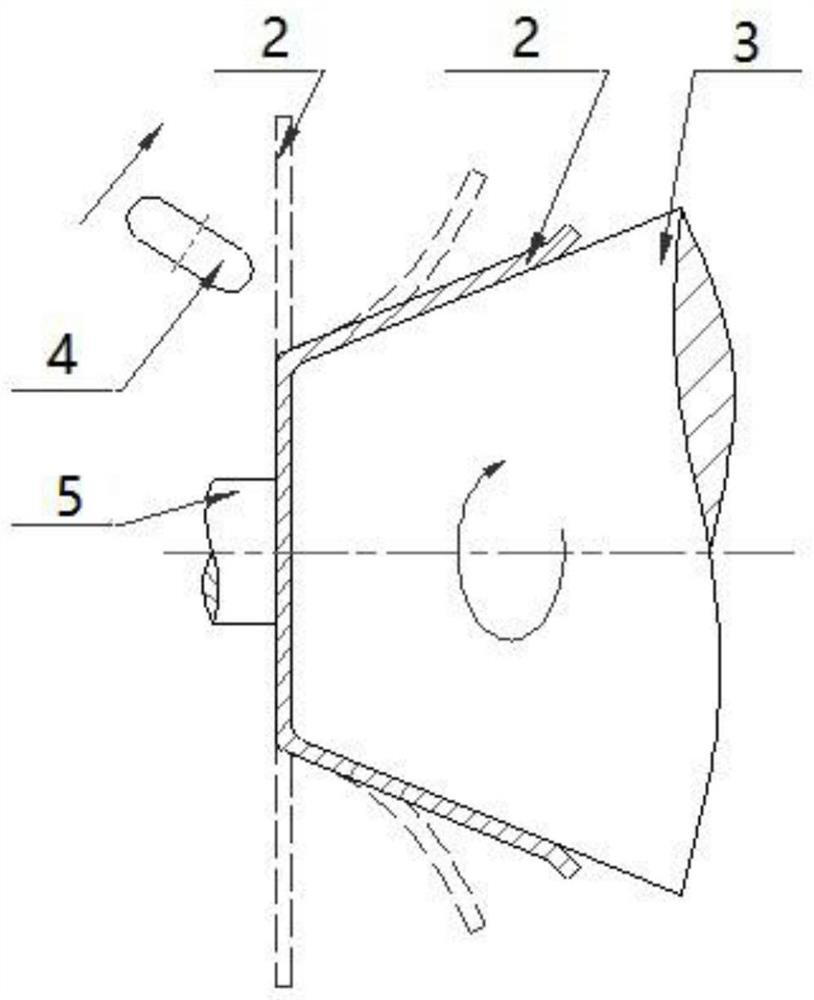

Image

Examples

Embodiment 1

[0052] Step 1: Design of the feed track of the rotary wheel: Design the feed track of the rotary wheel according to the structure of the part. Generally, the plate blank adopts the method of multi-pass spinning. By adjusting the appropriate thinning rate, this test is carried out for 5 passes. press forming;

[0053] Step 2: Select the number of induction heaters: In order to adapt to the complex shape of the blank in the spinning process, the length of each induction heater is generally greater than 50mm, and the displacement and rotation angle of each induction heater is controlled by the mechanical arm of the CNC equipment, and Select the appropriate number of segmented induction heaters according to the structure of the part to be processed to meet the requirement that the total length of the induction heater is not less than the length of the busbar of the part.

[0054] Step 3: Design the motion trajectory of the induction heater:

[0055] ①Before the spinning starts, t...

Embodiment 2

[0061] Step 1: Rotary wheel feed trajectory design: Design the rotary wheel feed trajectory according to the part structure. Generally, the plate-shaped blank adopts the method of multi-pass spinning. By adjusting the appropriate thinning rate, this test is carried out for 9 passes. press forming;

[0062] Step 2: Select the number of induction heaters: In order to adapt to the complex shape of the blank in the spinning process, the length of each induction heater is generally greater than 50mm, and the displacement and rotation angle of each induction heater is controlled by the mechanical arm of the CNC equipment, and Select the appropriate number of segmented induction heaters according to the structure of the part to be processed to meet the requirement that the total length of the induction heater is not less than the length of the busbar of the part.

[0063] Step 3: Design the motion trajectory of the induction heater:

[0064] ①Before the spinning starts, the track of...

Embodiment 3

[0070] Step 1: Rotary wheel feed trajectory design: Design the rotary wheel feed trajectory according to the part structure. Generally, the plate-shaped blank adopts the method of multi-pass spinning. By adjusting the appropriate thinning rate, this test is carried out 7 passes. press forming;

[0071] Step 2: Select the number of induction heaters: In order to adapt to the complex shape of the blank in the spinning process, the length of each induction heater is generally greater than 50mm, and the displacement and rotation angle of each induction heater is controlled by the mechanical arm of the CNC equipment, and Select the appropriate number of segmented induction heaters according to the structure of the part to be processed to meet the requirement that the total length of the induction heater is not less than the length of the busbar of the part.

[0072] Step 3: Design the motion trajectory of the induction heater:

[0073] ①Before spinning starts, the trajectory of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com