Invisible appliance production method

An invisible appliance and production method technology, applied in medical science, dentistry, laser welding equipment, etc., can solve the problems of affecting the patient's wearing and orthodontic effect, and the smoke and dust are unfavorable to the quality of the appliance, so as to reduce subsequent quality defects and have a beautiful appearance. , The effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

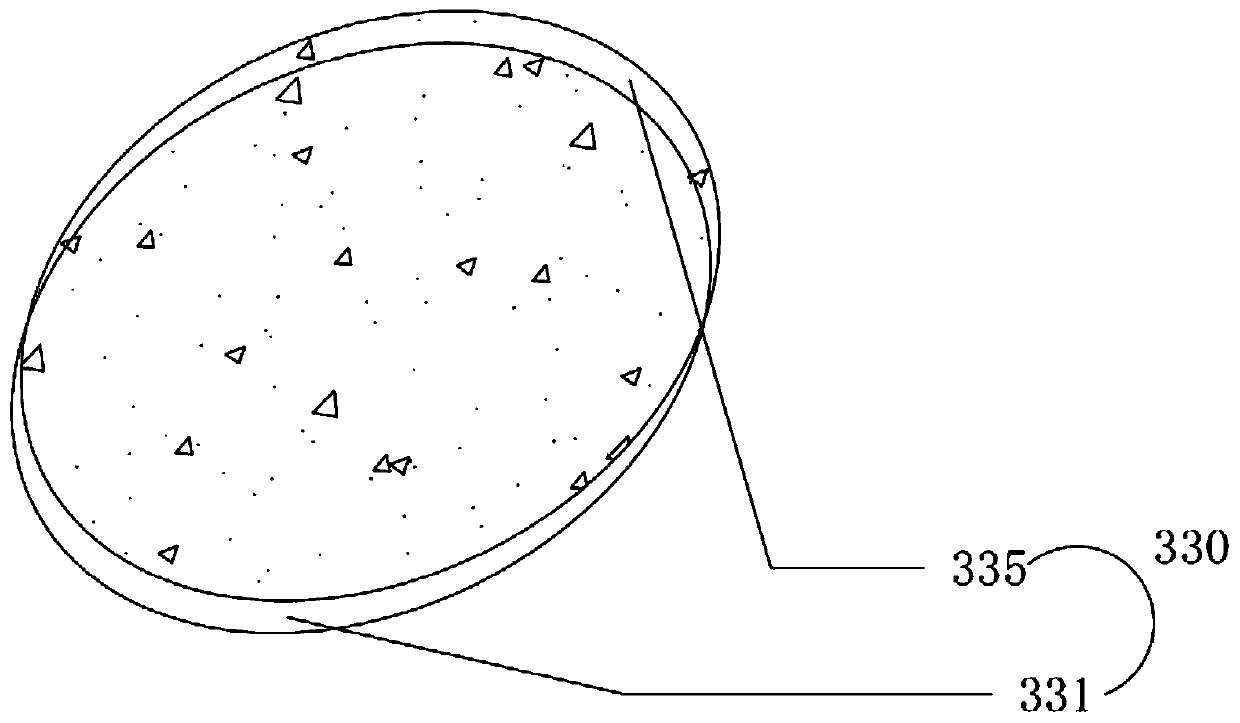

[0054] See image 3 , the invisible aligner production method of the present embodiment comprises the following steps:

[0055] Provide a diaphragm 331 for making invisible aligners; provide a process film 335;

[0056] A layer of process film 335 is set on the outer surface of the diaphragm 331 to obtain a diaphragm composite film 330; in the diaphragm composite film, the process film 335 is substantially equal in size to the diaphragm 331, and the process film 335 can cover the position of the cutting path The film at the place; specifically, the process film 335 and the film 331 are combined in a rolling manner, and in an alternative embodiment, the process film 335 and the film 331 can also be pasted, Electrostatic or hot pressing mode combination; Specifically, the specific operation mode of process film being arranged on the diaphragm can be to cover the continuous process film 335 on the continuous diaphragm 331 first, and then obtain the circular composite film 330 by...

Embodiment 2

[0065] See Figure 4 , the invisible aligner production method of the present embodiment comprises the following steps:

[0066] Provide a diaphragm 431 for making invisible aligners; provide a process film 435; the size of the process film 435 is smaller than the diaphragm 431;

[0067] A layer of process film 435 is set on the outer surface of the diaphragm 431 to obtain a diaphragm composite film 430; in this embodiment, the process film 435 is combined with the diaphragm 431 in a sticky manner In an embodiment, the process film 435 and the diaphragm 431 can also be combined by static electricity, extrusion, hot pressing, etc.; the process film 435 can cover the diaphragm at the position of the cutting path; specifically, it can be continuous The process film 435 is arranged on the continuous film sheet 431, and then cut to obtain Figure 4 The disc-shaped diaphragm composite membrane 430 shown in ; or it can also be that the circular diaphragm 431 and the process film 43...

Embodiment 3

[0076] See Figure 5 , the invisible aligner production method of the present embodiment comprises the following steps:

[0077] Provide a diaphragm 531 for making invisible aligners; provide a process film 535; the size of the process film 535 is smaller than the diaphragm 531, and is U-shaped;

[0078] A layer of process film 535 is set on the outer surface of the diaphragm 531 to obtain a diaphragm composite film 530; in this embodiment, the process film 535 is electrostatically combined with the diaphragm 531, and in addition In an embodiment, the process film 535 and the diaphragm 531 can also be combined by pasting, extrusion, hot pressing, etc.; the process film 535 can cover the diaphragm at the position of the cutting path, but the process film 535 It does not cover the part of the film 531 other than the position of the invisible aligner; specifically, the process film 535 can be continuously placed on the continuous film 531 first, and then cut to obtain Figure 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com