Method for preparing glycitein by taking bean germ as raw material

A technology of glycitein and soybean navel, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problem of no detection of soybean isoflavones, etc., and achieve the effect of low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

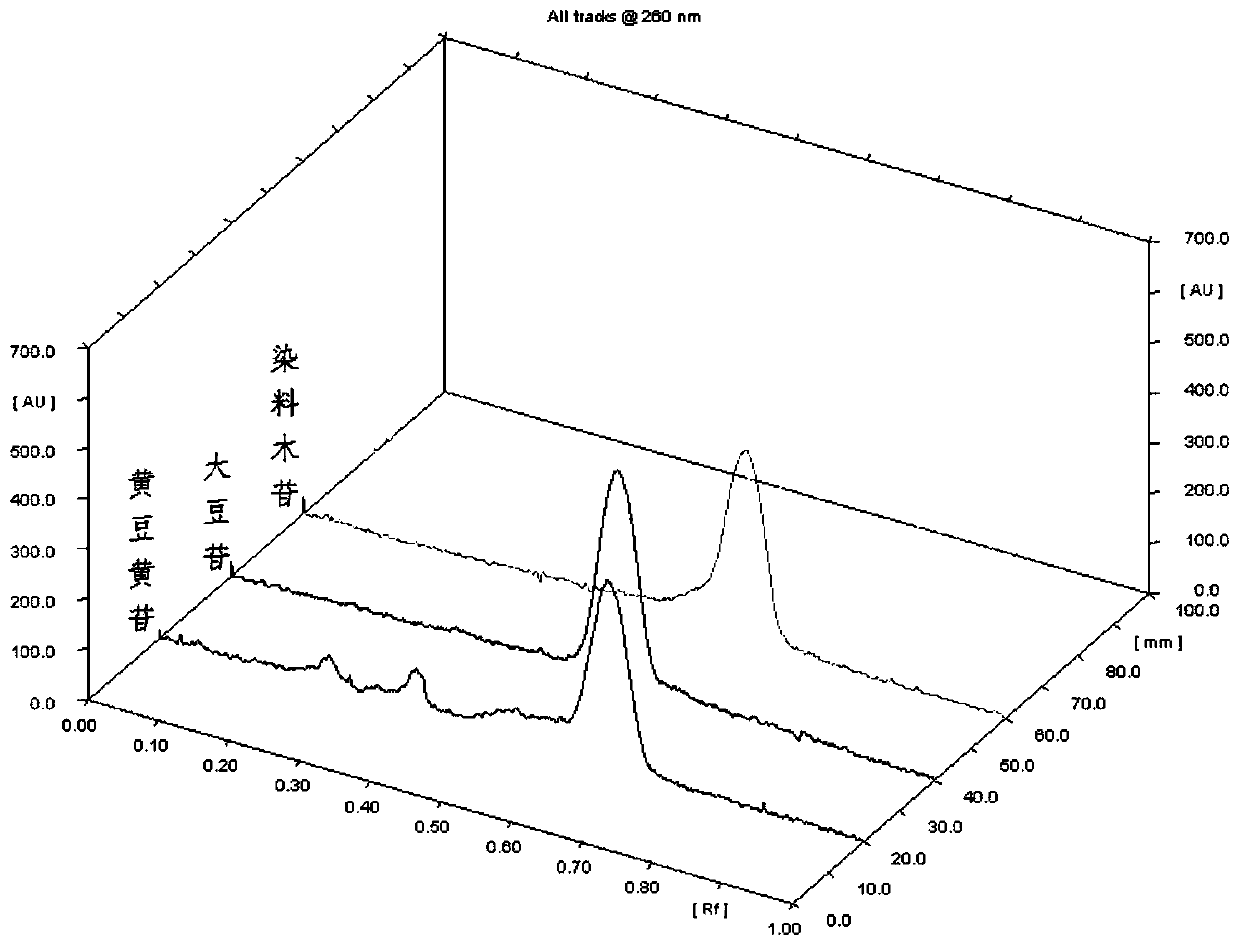

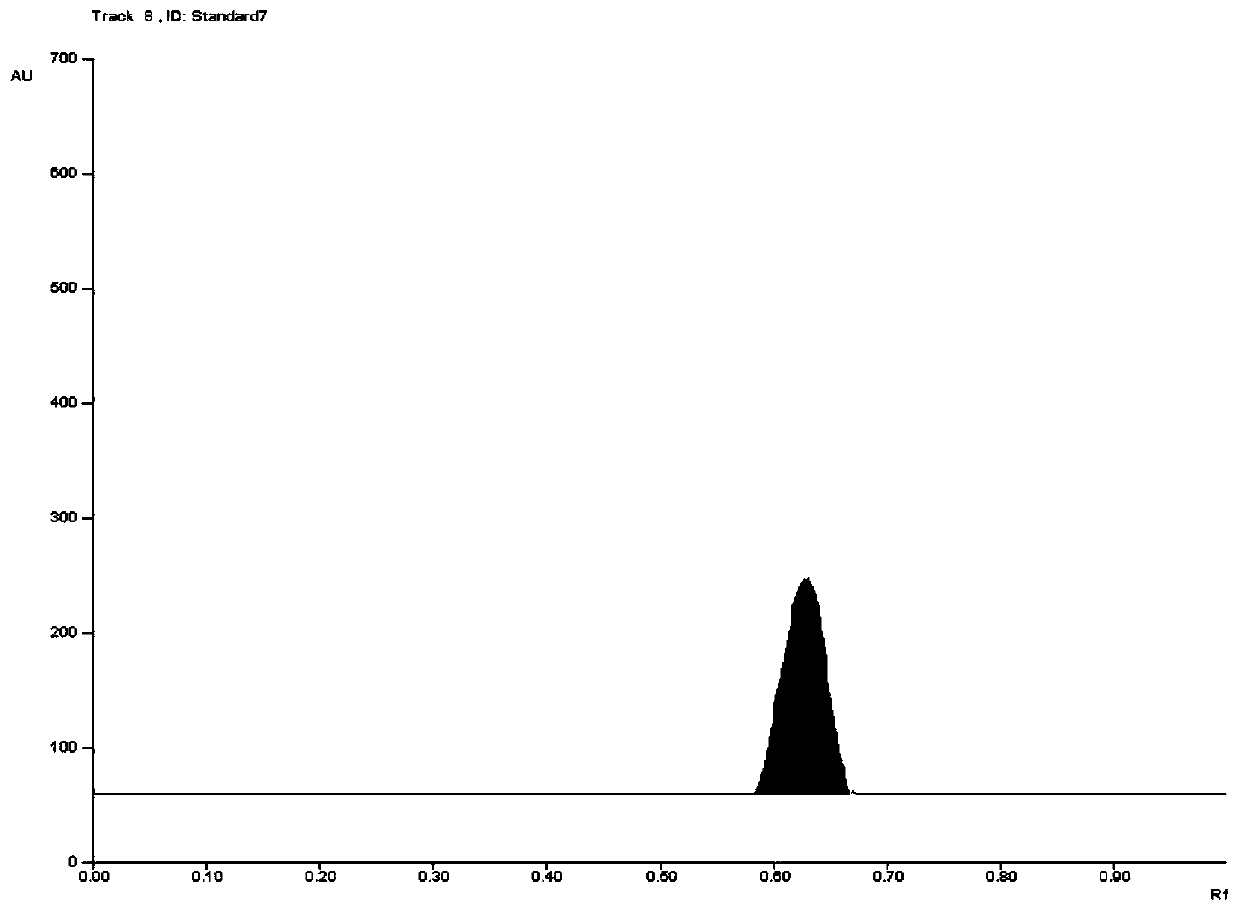

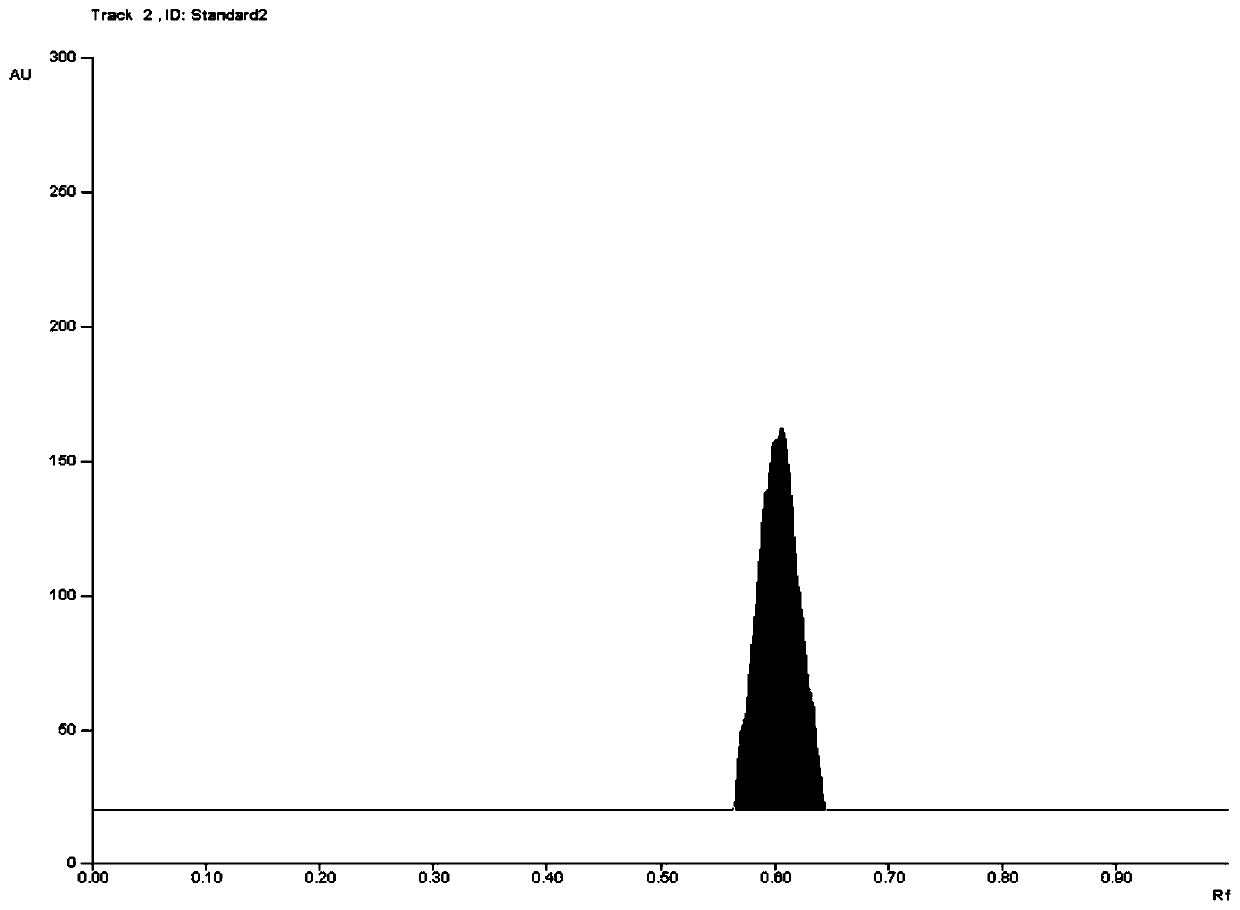

Image

Examples

Embodiment 1

[0038] Take 100g of bean navel powder of 80-100 mesh, add 550mL of 60% ethanol, stir and extract at 50°C for 1h, and spin-evaporate 400mL of the filtrate until the dry matter is 2g. Add 20 mL of n-hexane to the dry matter, shake and extract for 10 min, centrifuge at 1000-1500 r / min for 5 min, discard the supernatant to obtain residue. Add 20 mL of ethyl acetate to the slag, shake and extract for 15 minutes, centrifuge at 1000-1500 r / min for 10 minutes to obtain the supernatant, remove the ethyl acetate by rotary evaporation to obtain 10.7 mg glycitein, the purity of glycitein is 88%.

Embodiment 2

[0040] Take 100g of bean navel powder of 80-100 mesh, add 600mL of 55% ethanol, stir and extract at 60°C for 1h, and spin-evaporate 450mL of the filtrate until the dry matter is 1.5g. Add 15 mL of n-hexane to the dry substance, shake and extract for 20 minutes, centrifuge at 1000-1500 r / min for 10 minutes, discard the supernatant to obtain residue. Add 15 mL of ethyl acetate to the slag, extract by shaking for 20 min, centrifuge at 1000-1500 r / min for 5 min to obtain the supernatant, remove the ethyl acetate by rotary evaporation to obtain 11 mg of glycitein, the purity of glycitein is 90%.

Embodiment 3

[0042] Take 100g of bean navel powder of 80-100 mesh, add 500mL of 65% ethanol, stir and extract at 55°C for 45 minutes, and spin-evaporate 350mL of the filtrate until the dry matter is 2g. Add 20 mL of n-hexane to the dry substance, shake and extract for 15 minutes, centrifuge at 1000-1500 r / min for 8 minutes, discard the supernatant to obtain residue. Add 20 mL of ethyl acetate to the slag, extract by shaking for 20 min, centrifuge at 1000-1500 r / min for 8 min to obtain the supernatant, remove the ethyl acetate by rotary evaporation to obtain 10.4 mg glycitein, the purity of glycitein is 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com