Method for manufacturing non-woven refined dry flax punched felt

A manufacturing method, the technology of fine-drying hemp, which is applied in textiles and papermaking, non-woven fabrics, and improved hand-feeling fibers, etc., can solve the problems of hemp fiber being punctured, a large amount of raw material planting, and high tensile strength, and achieve full degumming , reduce fracture, reduce the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

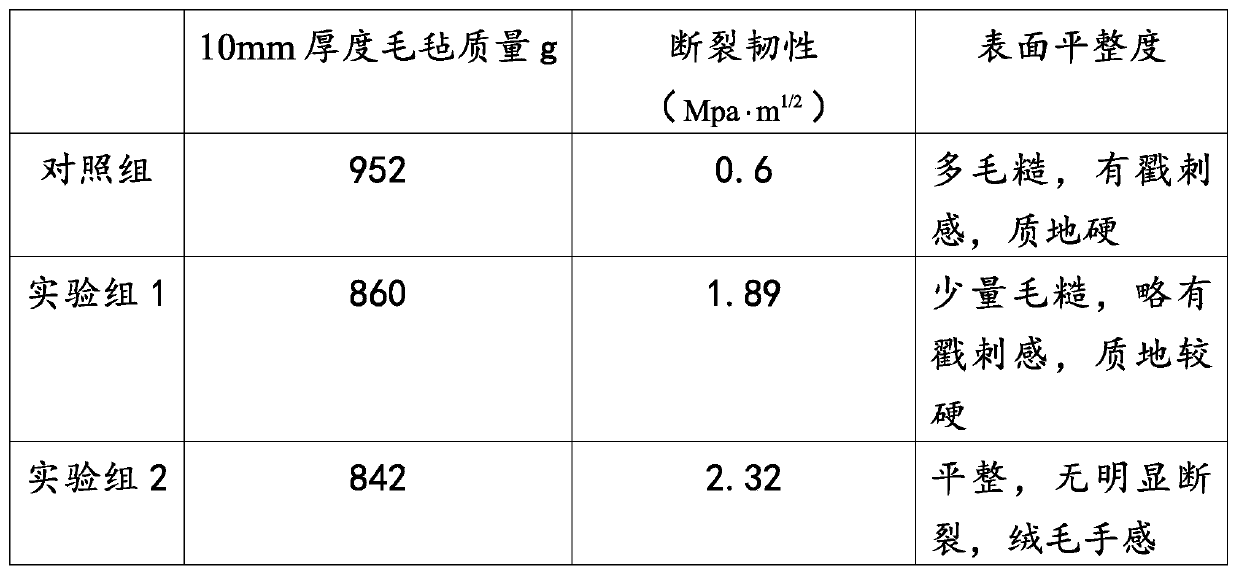

Examples

Embodiment Construction

[0015] The steps of the manufacturing method of the present invention are as follows: the fine-dried hemp is firstly subjected to degumming treatment, and the processed refined-dried hemp and Mongolian hemp fibers are mixed according to a mass ratio of 1:1 and added to an opener, and after being opened for 30 minutes, they are poured into a cotton mixing box for refining. Opening treatment, the finely opened raw cotton material is fed into the cotton box by air pressure and poured into the carding machine. The carding machine entangles the fibers of the raw cotton material in the forward direction into a mesh felt board. After forming a web, take the tray and put the mesh felt The board is placed on the tray, and the surface is sprayed with a special fiber softening agent. The amount of fiber softening agent is immersed in the mesh felt board, soaked for 1 hour, and dried in a drying oven. When the fluffiness of the mesh felt board reaches 450, stop drying , using acupuncture e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com