Binary horizontal burner

A binary horizontal, burner technology, applied in burners, combustion methods, combustion equipment and other directions, can solve problems such as environmental pollution, high energy consumption, carbon deposition, etc., to eliminate potential safety hazards, high energy utilization, environmental protection protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

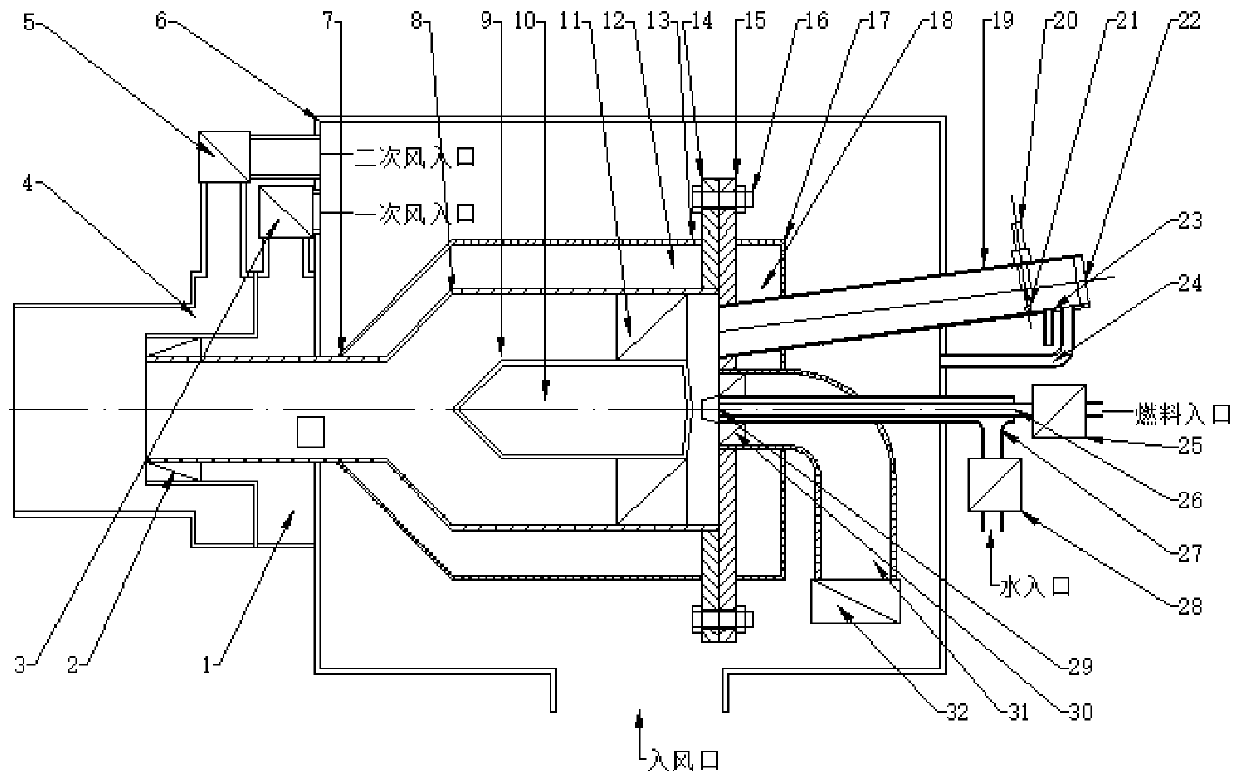

[0024] Specific implementation mode one: as figure 1 As shown, the binary horizontal burner of this embodiment includes a primary air supply chamber 1, a primary air distribution door 3, a secondary air supply chamber 4, a secondary air distribution door 5, a bellows 6, a mouth section 7, a cavity 8, Shock-absorbing heat collector 9, heat-resistant body 10, cavity flange 14, gland flange 15, gland insulation layer guard plate 17, ignition observation tube 19, observation mirror 22, ignition fluid input pipe 23, oxygen supply Pipe 24, fuel pipe 26, water supply pipe 27, mixing nozzle 29, main air duct 31, multiple first wind guide plates 2, multiple wind guide plates 30 and multiple fuel guide plates 11; the main structure of the burner is arranged on the air box 6, the cavity flange 14 and the inlet end of the cavity 8 are fixed as a whole, and the outlet end of the cavity 8 is coaxially connected with the cavity section 7, and the free end of the cavity section 7 is passed th...

specific Embodiment approach 2

[0028] Specific implementation mode two: as figure 1 As shown, in this embodiment, a plurality of fuel guide plates 11 are evenly distributed along the circumferential direction of the damping heat collector 9 . Such a design makes the fuel and water fully mixed and evenly mixed with air for combustion and cracking, and the angle of the guide plate determines the speed of its outlet. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: as figure 1 As shown, the air outlet of the main air duct 31 in this embodiment is uniformly provided with a plurality of air guide plates 30 along its circumferential direction. Such a design makes the air entering the main air duct 31 form a swirl wind, agitating the mixture of fuel and water into the cavity 8 evenly. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com